Reactive brilliant yellow dye and composite reactive brown dye

A technology for reactive brilliant yellow and brown dyes, applied in the field of dyes, can solve the problems of poor reproducibility of compositions and low practicability of composite reactive brown dyes, and achieve the effects of good compatibility, shortened dyeing process time, and pure color light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

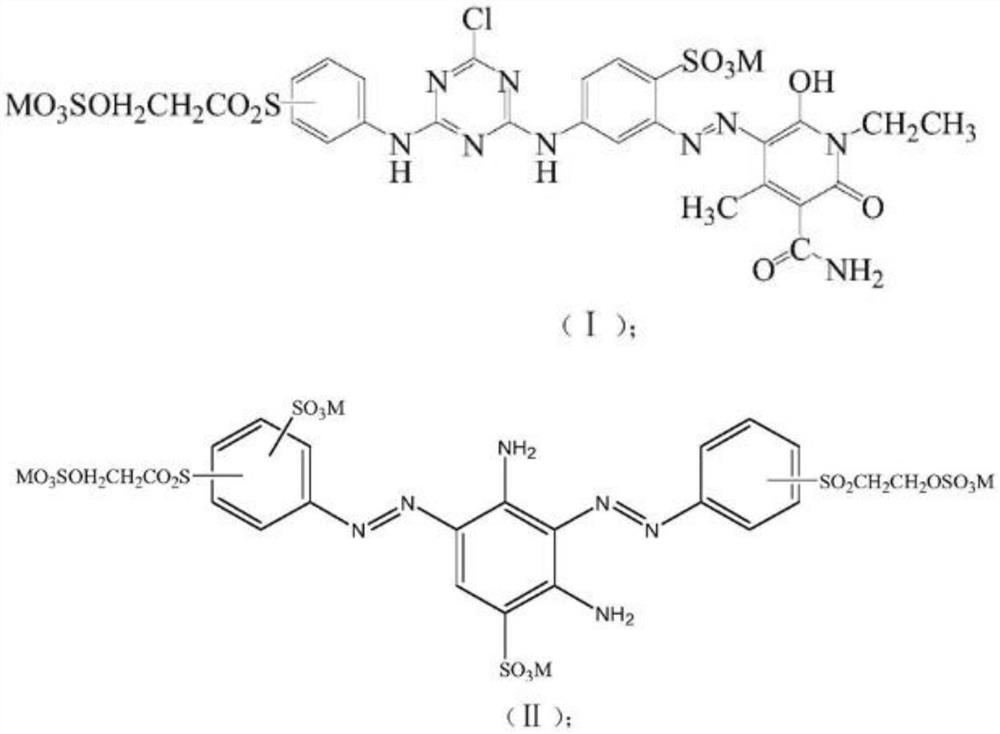

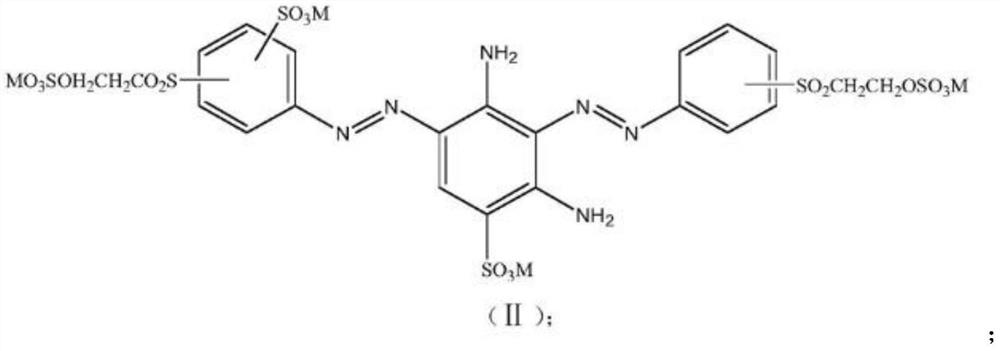

[0034] A reactive brilliant yellow dye and composite reactive brown dye, including reactive brilliant yellow dye comprising component A shown in formula (I) and component B shown in formula (II);

[0035]

[0036] Wherein, M in formula (I) and formula (II) is independently H, Na, K or Li;

[0037] Formula (I) accounts for 6-12% of the mass percentage of reactive brilliant yellow dye;

[0038] Formula (II) accounts for 80-90% of the mass percentage of reactive brilliant yellow dye;

[0039] The active brilliant yellow dye also includes alkali metal sulfate with a mass percent content of 5-8%.

[0040] Among the present invention, alkali metal sulfate is selected from the combination of one or more in sodium sulfate, potassium sulfate and lithium sulfate.

[0041] The preparation method of reactive brilliant yellow dye comprises the following steps: carry out diazotization reaction with hydrochloric acid and sodium nitrite to p-position ester, obtain diazonium salt, then mi...

Embodiment 2

[0054] A reactive brilliant yellow dye and composite reactive brown dye, including reactive brilliant yellow dye comprising component A shown in formula (I) and component B shown in formula (II);

[0055]

[0056] Wherein, M in formula (I) and formula (II) is independently H, Na, K or Li;

[0057] Formula (I) accounts for 8-12% of the mass percentage of reactive brilliant yellow dye;

[0058] Formula (II) accounts for 80-85% of the mass percentage of reactive brilliant yellow dye;

[0059] The active brilliant yellow dye also includes alkali metal sulfate with a mass percent content of 5-8%.

[0060] Among the present invention, alkali metal sulfate is selected from the combination of one or more in sodium sulfate, potassium sulfate and lithium sulfate.

Embodiment 3

[0062] A reactive brilliant yellow dye and a composite reactive brown dye include a composite brown dye, the composite brown dye includes dye A, dye B and dye C, the dye is formula (II), and the parts by weight of each component are: 85 parts of dye A, 40 parts of dye B, 20 parts of dye C;

[0063] The structural formula of dye A is:

[0064]

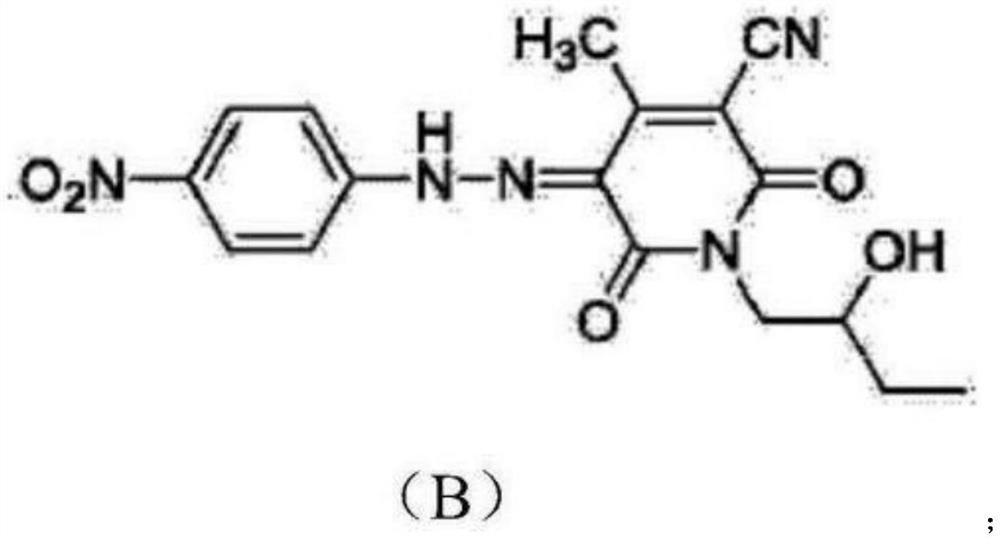

[0065] The structural formula of dye B is:

[0066]

[0067] The structural formula of dye C is:

[0068]

[0069] Among the present invention, composite brown dyestuff also includes C.I reactive orange 107, reactive dark blue M-R, C.I reactive blue 203, reactive deep red and reactive red SHE are active ingredients, supplemented with standardized auxiliary agent system.

[0070] In the present invention, the mass content of the active ingredient is 85-90%.

[0071] Among the present invention, standardization auxiliary agent is selected from one or more in sodium sulfate, diffusing agent NNO, diffusing agent MF, alkali-resis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap