Underground cable safe laying method

An underground cable and safety technology, which is applied in the field of power cables, can solve the problems of no cable laying monitoring, the lower part is easily damped, and the construction is inconvenient, and achieves the effect of convenient construction, enhanced shock absorption effect, and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

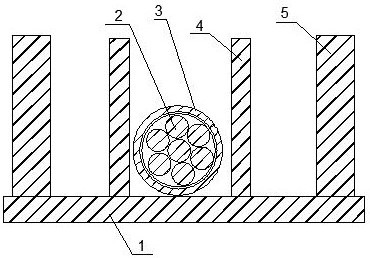

[0035] like Figure 1-2 As shown, the present embodiment provides a method for safely laying underground cables, comprising the following steps:

[0036] S1: Investigate the terrain and the presence or absence of obstacles in the section where the cable line passes, check and record the length of each section;

[0037] S2: Pouring protective foundation;

[0038] S3: Excavating cable trenches;

[0039] S4: Implant the protective foundation and lay cables.

[0040] In the step S3, the excavation depth of the cable trench is 1-1.5m. In case of obstacles or areas with shallow permafrost, it should be deepened appropriately: the corner of the cable trench should be dug into an arc shape, and the allowable bending radius of the cable should be ensured: where the cable joint is introduced into the building or from the pole The residual pit for spare cable margin shall be dug out.

[0041] In the step S4, the bottom plate is implanted first, then cables are laid, the cover plate ...

Embodiment 2

[0043] like Figure 1-2 As shown, this embodiment provides a method for safely laying underground cables, which is an improvement on the basis of Embodiment 1:

[0044] In the step S2, the protection foundation is formed by pouring concrete.

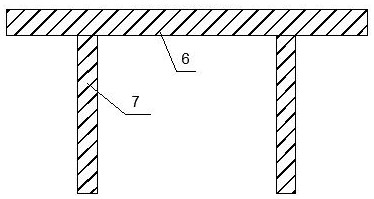

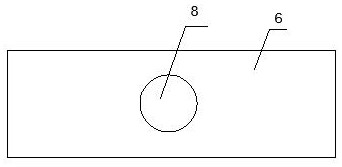

[0045] The protective foundation includes a cover plate 6, a base plate 1, and two side plates 5 arranged at both ends of the base plate 1; the base plate 1 is provided with a first support plate 4, and the cover plate 6 is provided with a second Support plate 7.

[0046] The bottom plate 1, the side plate 5 and the first support plate 4 are formed by one-time pouring, and the cover plate 6 and the second support plate 7 are formed by one-time pouring.

[0047] Two first support plates 4 are arranged on the bottom plate 1 , and the cable is located between the two first support plates 4 .

[0048] Two second support plates 7 are arranged on the cover plate 6 , and when closed, the two second support plates 7 are respectively located b...

Embodiment 3

[0055] like Figure 1-2 As shown, this embodiment provides a method for safely laying underground cables, which is an improvement on the basis of Embodiment 2:

[0056] In the step S4, the bottom plate is implanted first, then cables are laid, the cover plate is implanted, and soil is taken for backfilling.

[0057] Lay a layer of fine sand with a thickness of 2-3cm between the two first support plates, and then lay the cable, after that, lay fine sand on the surface of the cable, at the same height as the first support plate, the first support plate and the side plate A layer of fine sand with a thickness of 2-3cm is also laid in between, and the cover plate is implanted, compacted, backfilled with soil, and compacted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com