Continuous combined extrusion blooming method for difficult-to-deform superalloy ingot

A high-temperature alloy and composite extrusion technology, applied in the direction of metal extrusion dies, etc., can solve the problems of low material utilization rate and production efficiency, uneven deformation structure, insufficient extrusion ratio, etc., to improve material yield and increase Uniformity and flatness of tissue, effect of reducing residual stress level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Adopt the method described in the present invention to carry out the step of continuous compound extrusion blanking to GH710 alloy ingot as follows:

[0047] Step 1. Extrusion mold preparation

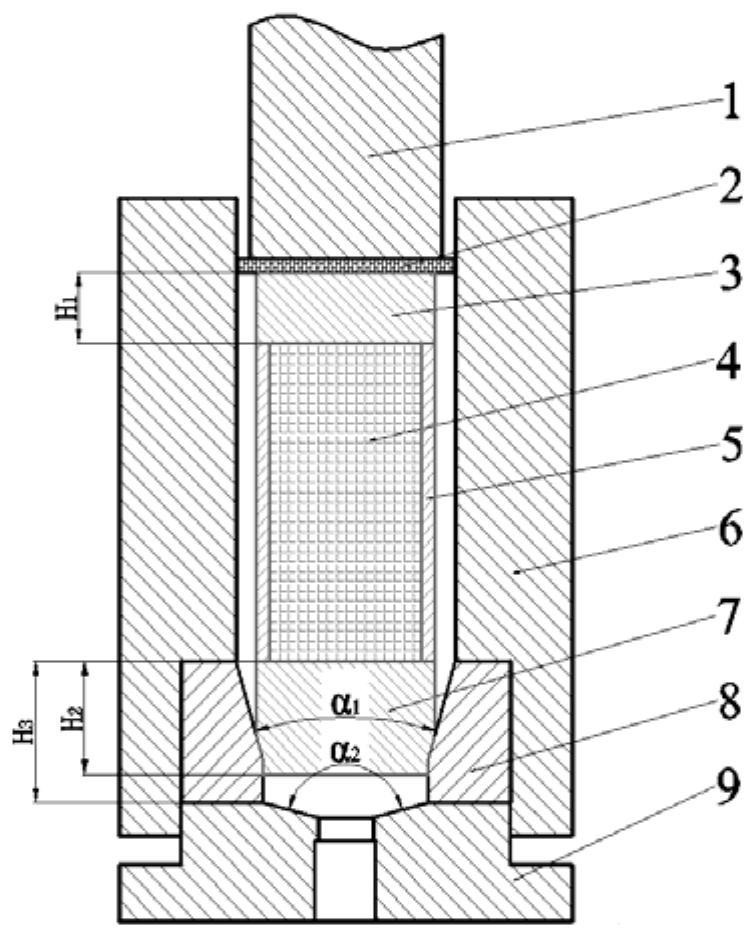

[0048] like figure 1 As shown, the method adopts an extrusion molding die including a punch 1, an extrusion steel pad 2, an extrusion cylinder 6, a reducing die 8, a positive extrusion die 9, a reducing die 8 and a forward extrusion die. The cooperation between the pressing die 9 and the extrusion barrel 6 is a transition fit, and is coaxial with the center line of the punch 1. The diameter reducing extrusion die 8 is composed of one insert, and the section reduction rate is designed to be 30%. Cone angle α 1 is 30°, the extrusion ratio of positive extrusion die 9 is designed to be 9:1, and the die cone angle α 2 is 160°;

[0049] Step 2. Package welding

[0050] The jacket material is made of 304 stainless steel. The unilateral gap between the inner diameter of the jacket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com