Modified PP material, preparation method and application thereof

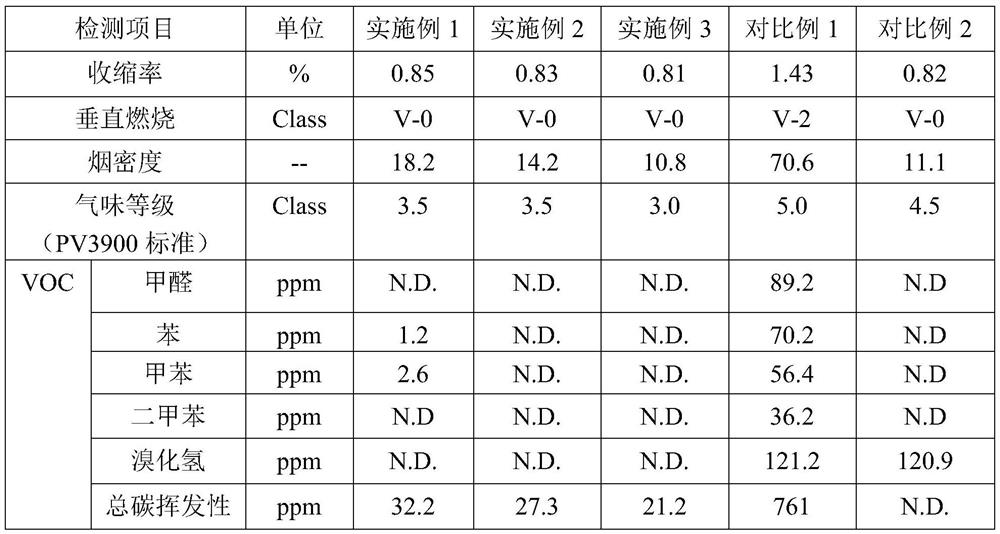

A modification and antioxidant technology, applied in the field of modified PP materials and its preparation, can solve the problems of high smoke density, high VOC content, and large material odor during flame retardancy, so as to improve flame retardancy efficiency and reduce shrinkage , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

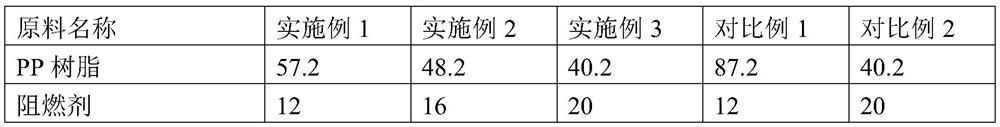

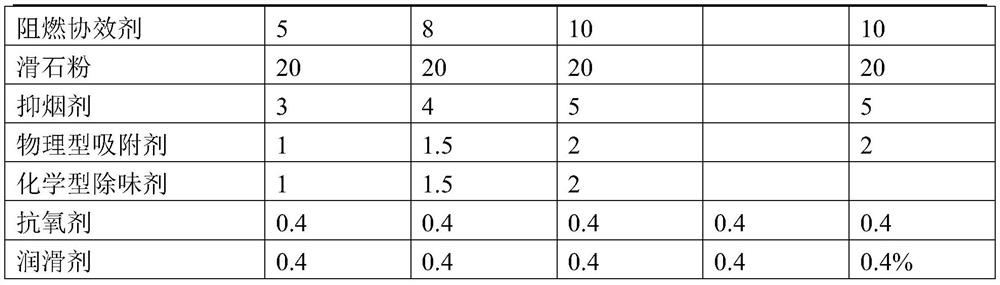

[0051] A kind of modified PP material, its raw material formula is shown in Table 1, and its preparation method comprises the following steps: mix PP resin with flame retardant, flame retardant synergist, talcum powder, smoke suppressant, physical type adsorbent, chemical Type deodorant, antioxidant, and lubricant are put into the high mixer and mixed evenly, then fed from the main feeding port of the extruder, melted, extruded, and granulated in the extruder to obtain modified PP materials .

[0052] The preparation method of the chemical type deodorant in the embodiment 1-3 is: immerse the activated carbon with the pore diameter of 100um in the silver nitrate solution with a concentration of 1mol / L, and let it stand for 48h under the environment of 50°C, so that the silver nitrate solution is fully immersed in the It can be obtained in the pores of activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com