Lead reducing slag treating method and device

A processing method and processing device technology, applied in the direction of improving process efficiency, etc., can solve the problems of waste of resources, high zinc and lead content, etc., and achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

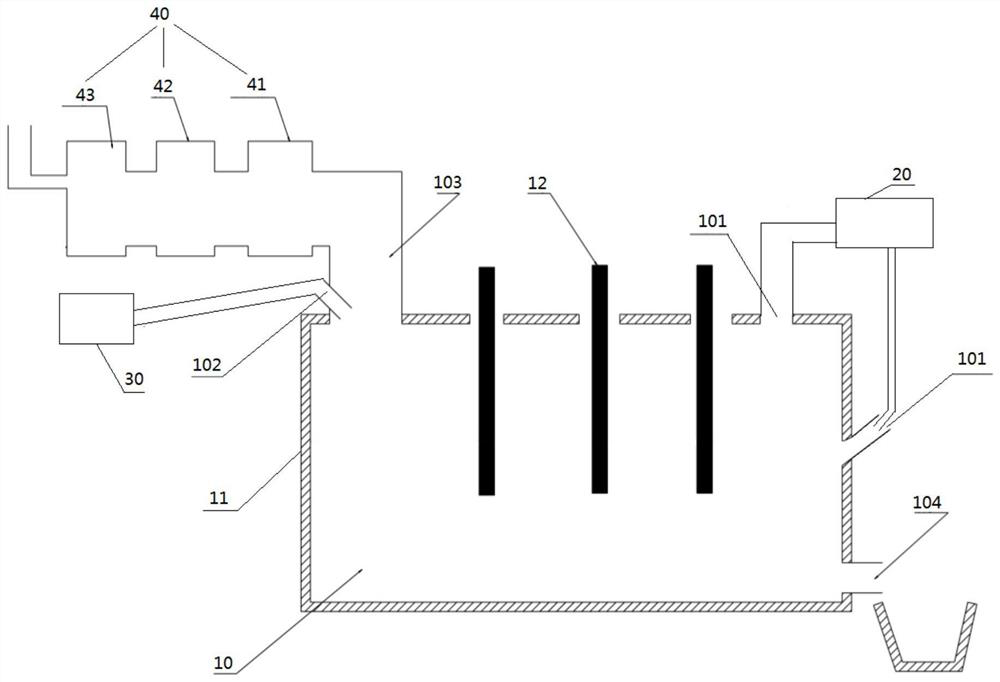

[0062] use figure 1 As shown in the processing device, the CR furnace includes a shell and an electrode. There is a cavity inside the shell, and the electrode passes through the shell and extends into the cavity for heat supply. The volume of the part where the electrode extends into the cavity accounts for the total volume of the cavity. 5.5% of volume. The way of adding the reducing agent is to directly add the reducing agent inlet on the top of the shell, and pass the granular reducing agent into the cavity through the belt conveyor. An air leakage port is arranged above the molten pool on the side of the shell.

[0063] The lead reduction slag is added into the CR furnace in the form of liquid hot slag by the launder, and the lignite particles of 5-30mm are transported to the chamber through the belt conveyor, and the amount added is 6% of the lead reduction slag to increase the temperature of the slag in the furnace To 1460°C, the power density in the cavity is 210kW / m ...

Embodiment 2

[0067] use figure 1 As shown in the processing device, the CR furnace includes a shell and an electrode. There is a cavity inside the shell, and the electrode passes through the shell and extends into the cavity for heat supply. The volume of the part where the electrode extends into the cavity accounts for the total volume of the cavity. 5.5% of volume. The reducing agent is added by wire feeding. There are 15 wire feeding holes with a diameter of 20mm on the top and side of the shell. The carbon powder wire is coke powder wrapped in aluminum skin with a thickness of 0.1mm, and the carbon content is 99wt%. An air leakage port is arranged above the molten pool on the side of the shell.

[0068] The lead reduction slag is added into the CR furnace in the form of liquid hot slag by the launder, and the carbon powder is fed into the chamber to raise the temperature of the slag in the furnace to 1470°C, and the power density in the chamber is 220kW / m 2 , carry out electrothermal...

Embodiment 3

[0072] use figure 1 As shown in the processing device, the CR furnace includes a shell and an electrode. There is a cavity inside the shell, and the electrode passes through the shell and extends into the cavity for heat supply. The volume of the part where the electrode extends into the cavity accounts for the total volume of the cavity. 5.5% of volume. The way of adding the reducing agent is spraying the top and side spray guns of the shell. One spray gun is set on the top and two spray guns are installed on the side, which are used to spray the powdered reducing agent with nitrogen as the carrier. An air spray gun is arranged above the molten pool at the side of the housing for injecting air into the molten pool.

[0073] The lead reduction slag is added into the CR furnace in the form of liquid hot slag using a launder. The powdered reducing agent is coke powder with a particle size higher than 200 mesh powder accounting for ≥ 50 wt%, and the amount added is 5% of the lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com