Efficient asphalt melting device for road construction

A technology of road construction and melting device, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of reduced melting rate and large area of solid asphalt, and achieve the effects of ensuring stability, avoiding waste, and accelerating melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

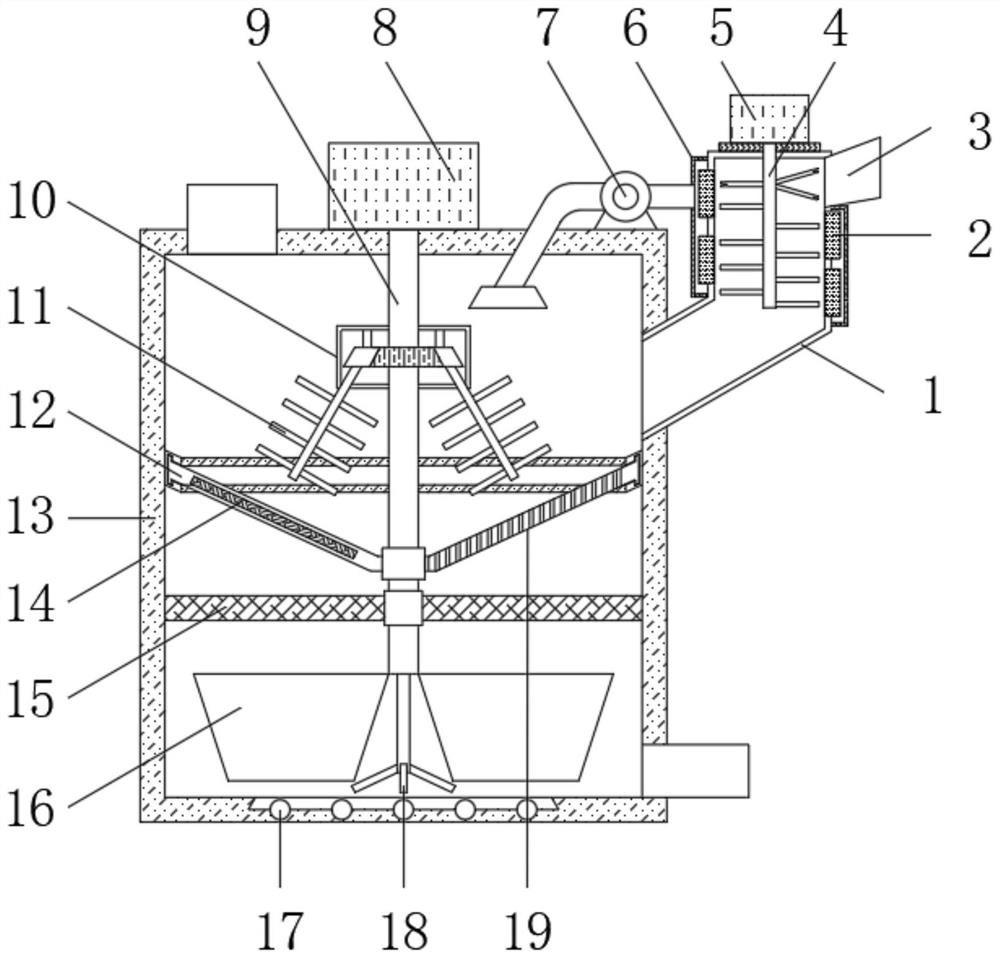

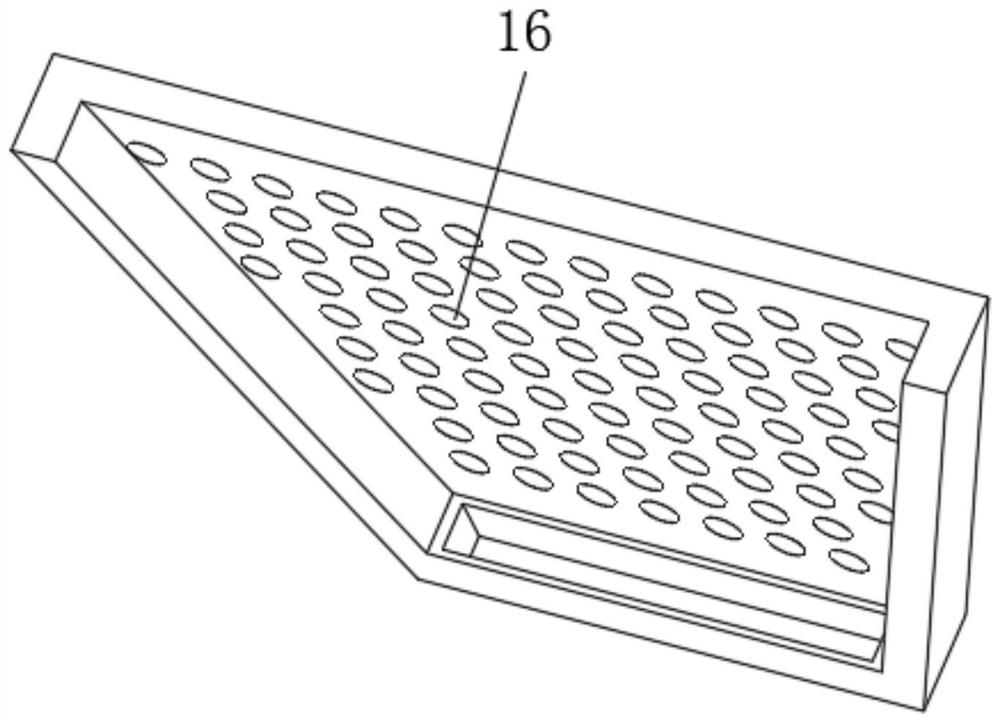

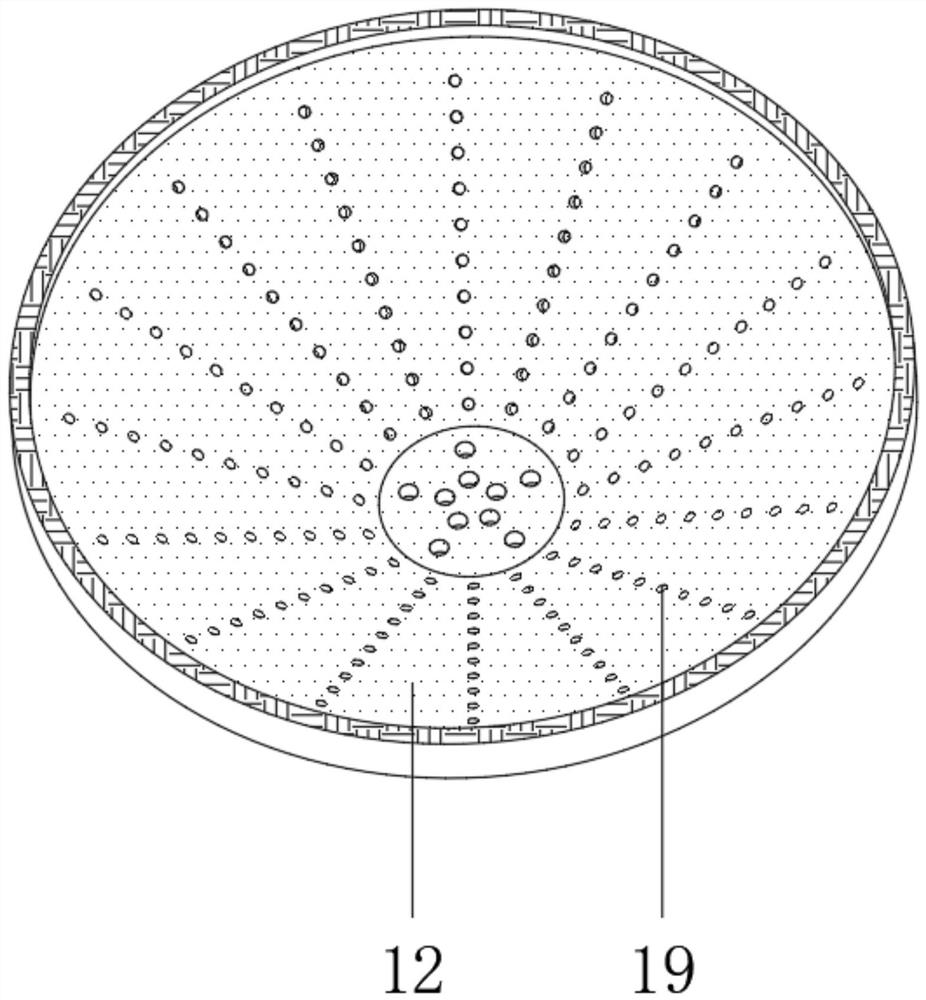

[0026] refer to Figure 1-4 , an asphalt high-efficiency melting device for road construction, comprising a housing 13, a crushing cylinder 1 is fixedly inserted into the upper end of the outer wall of one side of the housing 13, and a crushing motor 5 is installed on the top of the crushing cylinder 1 through bolts, and the bottom end of the crushing motor 5 passes through The coupling rotates and installs a crushing roller 4, and the upper end of the peripheral outer wall of the crushing roller 4 is fixedly equipped with a scraping rod, and the middle and lower end of the peripheral outer wall of the crushing roller 4 is fixedly installed with crushing rods that are equally spaced and successively reduced. There is a feed hopper 3, and the outer wall of the crushing cylinder 1 is plugged with equidistant semiconductor refrigeration chips 2, the outer wall of the crushing cylinder 1 is fixedly installed with a heat recovery sleeve 6, and the outer wall of the top end of the sh...

Embodiment 2

[0036] refer to Figure 5 , a high-efficiency asphalt melting device for road construction, further, a feeding cylinder 21 is inserted on one side of the housing 13, and a sealing ring is inlaid at the connection between the feeding cylinder 21 and the housing 13, and the feeding cylinder 21 is located on the ring slide rail At the lower end, the outer wall of one side of the feeding cylinder 21 is provided with a feeding motor 20 through bolts, and the feeding motor 20 is fixedly installed with a screw feeding blade 22 through a rotating shaft, and the outer wall of the other side of the feeding cylinder 21 is provided with a drug outlet, and the top of the feeding cylinder 21 is fixed at an angle. A medicine feeding hopper is plugged in, and a support frame is installed between the lower end of the outer wall on one side of the housing 13 and the feeding cylinder 21 through bolts.

[0037] Working principle: The feeding cylinder 21 is inserted through one side of the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com