A film-like diffusion source forming machine

A diffusion source and forming machine technology, applied to spraying devices with movable outlets, electrical components, spraying devices, etc., can solve problems such as production difficulties, achieve the effects of improving stability, fast and convenient adjustment, and increasing space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

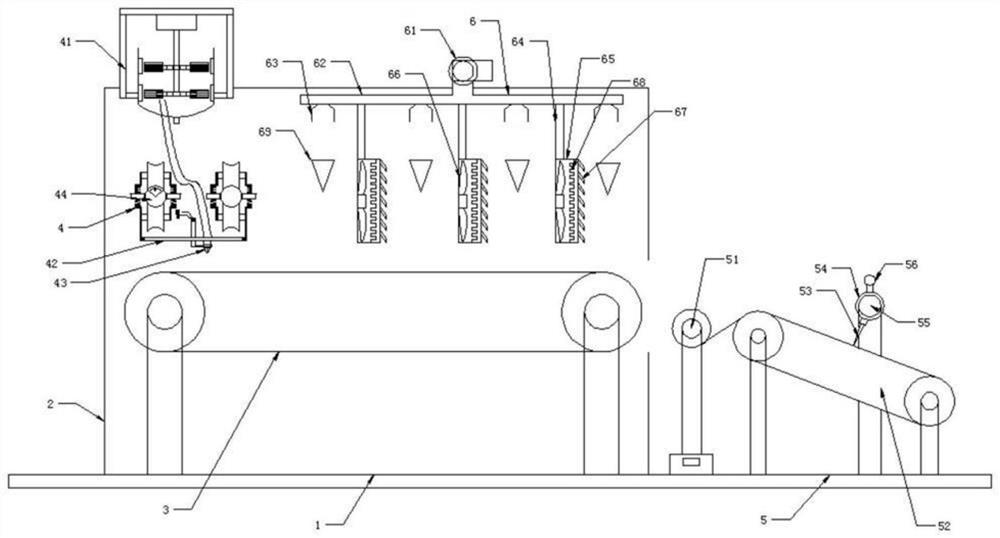

[0014] figure 1 It is a structural schematic diagram of a film-like diffusion source molding machine of the present invention, a film-like diffusion source molding machine, which is characterized in that it includes a base 1 and a frame 2, and a film-forming transfer roller 3 is arranged on the base 1, The film-forming conveying roller 3 comprises two groups of horizontal rollers parallel to each other and a stainless steel conveyor belt connecting the two rollers. One end of the film-forming conveying roller 3 is provided with a spraying device 4 and the other end is provided with a cutting device 5. One side of the spraying device 4 is provided with a drying device 6, and the spraying device 4 includes an emulsion mixing tank 41, the emulsion mixing tank 41 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com