Rotor, permanent magnet synchronous motor and manufacturing method of rotor

A manufacturing method and rotor technology are applied in the field of permanent magnet synchronous motor, rotor manufacturing, and rotor, which can solve the problems of difficult actual production and difficult stator insert production, and achieve the effect of reducing cogging torque and optimizing magnetic field distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

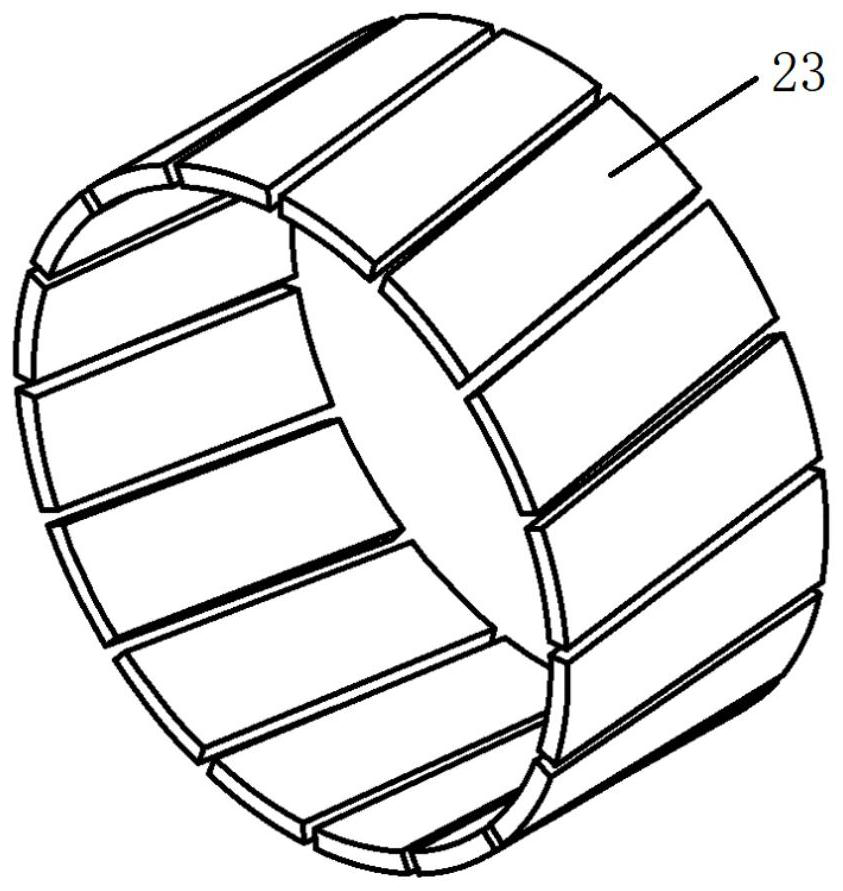

[0054] as attached figure 1 As shown, it is a rotor provided by an embodiment of the present invention, and the rotor includes:

[0055] Spindle 1;

[0056] The first rotor core part 2; a plurality of first rotor slots 3 spiraling along the first direction are evenly distributed in the circumferential direction of the first rotor core part 2;

[0057] The second rotor core part 4; the circumferential direction of the second rotor core part 4 is uniformly distributed with a plurality of second rotor slots 5 spiraling along the second direction; the second rotor slots 5 are connected with the first rotor The groove 3 communicates; the second direction is opposite to the first direction.

[0058] In this embodiment, both the first rotor core part 2 and the second rotor core part 4 are fixed on the rotating shaft 1 . Since the helical directions of the first rotor slot 3 and the second rotor slot 5 are opposite and the first rotor slot 3 and the second rotor slot 5 are arranged s...

Embodiment 2

[0072] An embodiment of the present invention also provides a permanent magnet synchronous motor, which includes: a motor housing, a stator, and the rotor described in any one of Embodiment 1.

[0073] In this embodiment, a permanent magnet synchronous motor is prepared by using the motor housing, the stator, and the rotor in the first embodiment, and the permanent magnet synchronous motor has all the advantages of the rotor in the first embodiment.

Embodiment 3

[0075] An embodiment of the present invention also provides a rotor manufacturing method, including the processing technology of the rotating shaft 1, the processing technology of the rotor core, the processing technology of the magnetic steel sheet and the assembly technology of the rotor.

[0076] As a preferred embodiment of the present invention, the processing technology of the rotating shaft 1 includes:

[0077] The OEM workpiece is clamped on the worktable of the vertical machining center with X-axis rotation function by clamping at one end and thimble at the other end;

[0078] The vertical milling cutter is used to process the OEM workpiece; the diameter of the vertical milling cutter is selected according to the width of the rotor groove on the rotor, so as to ensure that the width of the rotor groove and the tooth width of the rotor punch are transitionally matched; the spindle of the vertical machining center The speed is 1500rpm-2000rpm, and the axial feed speed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com