Cooler

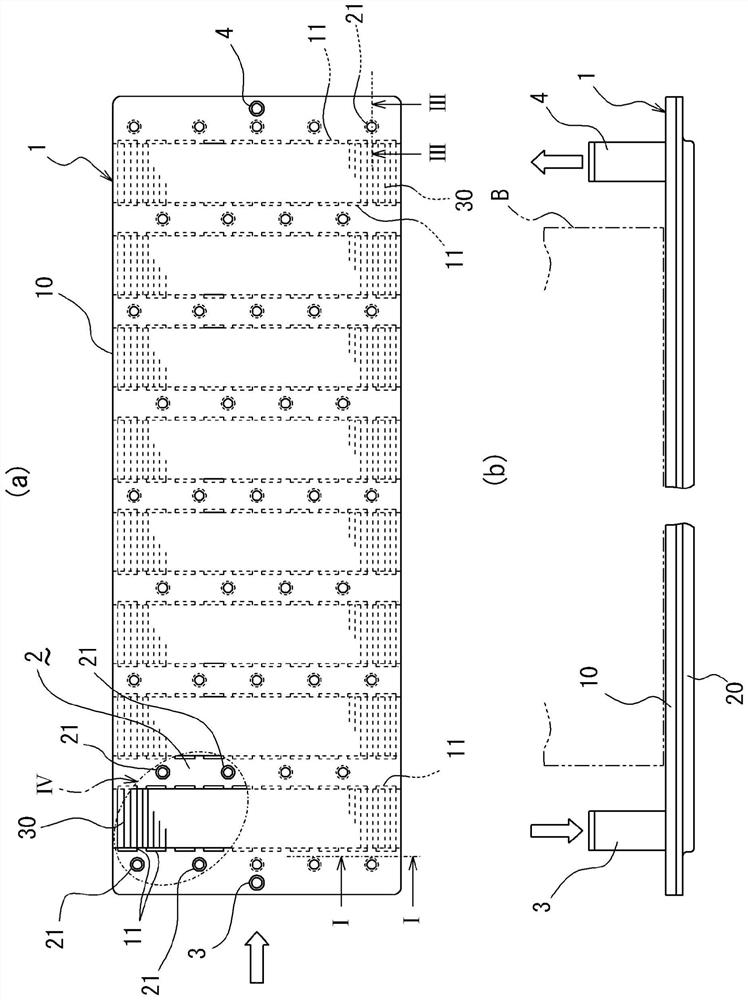

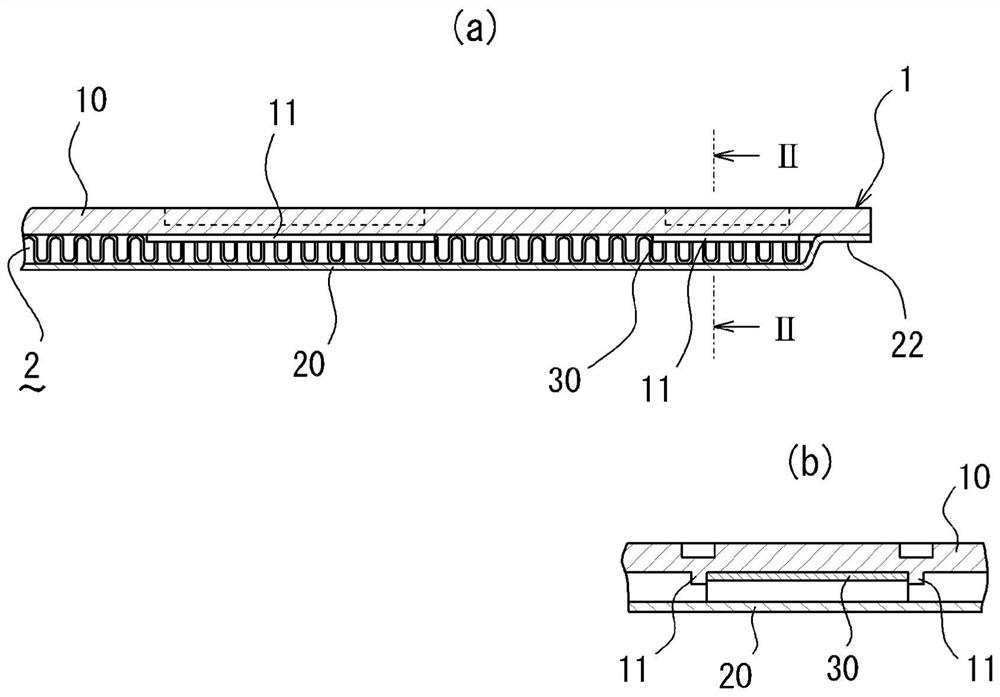

A cooler and refrigerant technology, applied in cooling/ventilation/heating transformation, semiconductor devices, electric solid devices, etc., can solve the problems of inability to cool batteries efficiently and uniformly, temperature unevenness, etc., achieve efficient and uniform cooling, suppress Effect of temperature deviation and suppression of turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Hereinafter, the analysis for examining the temperature nonuniformity (temperature variation) on the surface of the coolers (Examples 1 and 2) of the present invention and coolers not provided with protrusions (Comparative Examples 1 and 2) will be described.

[0065]

[0066] ·Corrugated fins

[0067] Thickness: 0.3mm, gap (distance between mountains and valleys): 1.5mm, length: 100mm

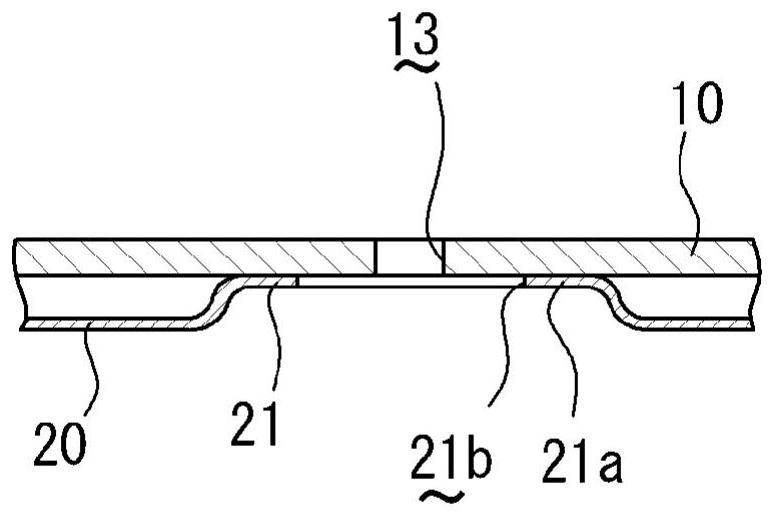

[0068] · Protrusion

[0069] Height: 1mm, Width: 2mm

[0070] ·Heating Department

[0071] Calorific value: 360W×2

[0072]

[0073] Density: 1038kg / m 3

[0074] Viscosity: 0.00128Pa·s

[0075] Specific heat: 3482J / (kgK)

[0076] Thermal conductivity: 0.424W / (mK)

[0077] Assume that the periphery of the cooler is all insulated, and all heat generated is cooled by heat exchange between the corrugated fins and the refrigerant. ANSYS Icepak R18.1 was used in the analysis.

[0078] Under the above conditions, after analyzing the situation where the refrigerant flow rate is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com