Polyimide reaction kettle capable of rotating bidirectionally and dissipating heat efficiently

A polyimide, two-way rotation technology, applied in chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, chemical instruments and methods, etc., can solve thermal insulation, poor thermal conductivity, polymerization solution Increased viscosity, uneven temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

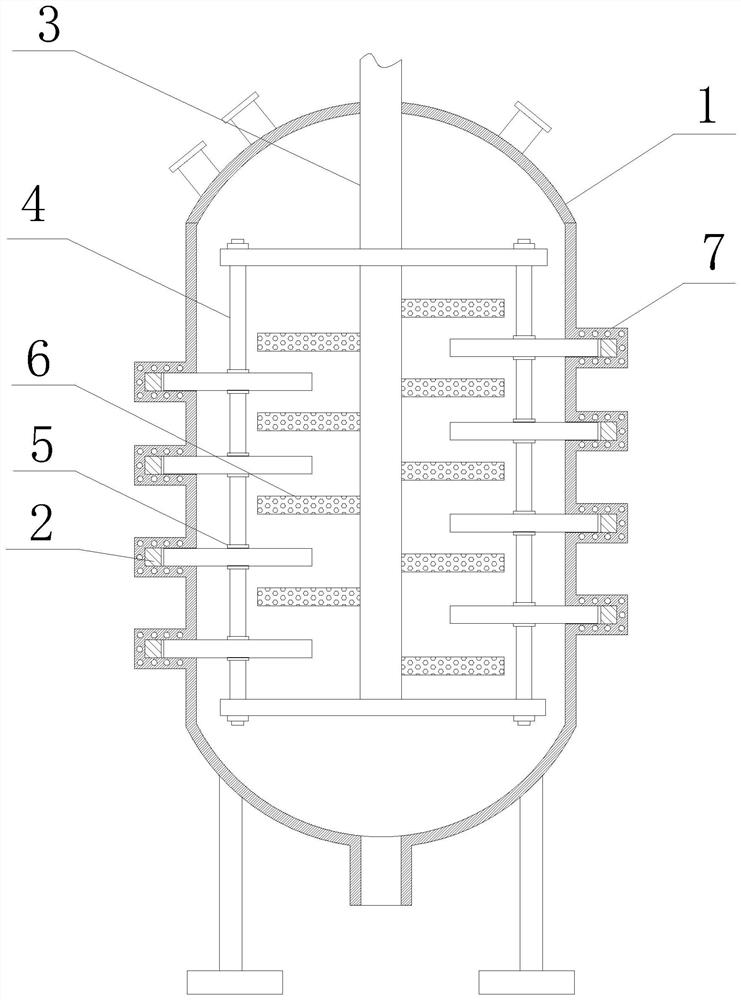

[0020] refer to figure 1 , a polyimide reaction kettle with two-way rotation and high-efficiency heat dissipation proposed by the present invention, comprising: a kettle body 1 and a driving mechanism, wherein: the inner surface of the kettle body 1 is embedded with a ring gear 2 coaxial with it, and the kettle body 1 There is a radiator inside.

[0021] The radiator includes a central rod 3, a plurality of auxiliary rods 4 and a plurality of rotating disks 5, the central rod 3 is connected with the driving mechanism and can be driven to rotate by the driving mechanism, and each auxiliary rod 4 is circumferentially arranged on the outside of the central rod 3 and connected with the central rod. 3 is fixedly connected so that it rotates with the rotation of the central rod 3. Each rotating disk 5 is rotated and installed on each sub-rod 4 in one-to-one correspondence. The rotating disk 5 is made of heat-conducting material, and the outer contour of the rotating disk 5 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com