Three-electrode discharge plasma auxiliary ball-milling tank

A discharge plasma and ball milling tank technology, which is applied in the fields of powder metallurgy and mechanical alloying, can solve the problems of affecting continuous use, discharge interruption, and short service life, so as to prevent discharge interruption, promote crushing and refinement, and improve powder activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

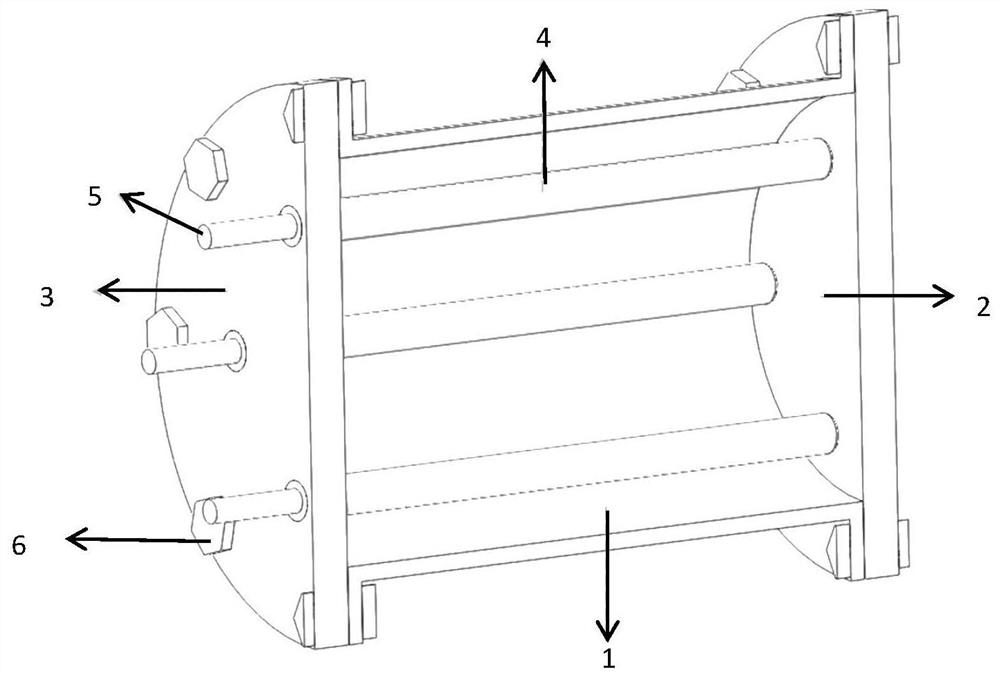

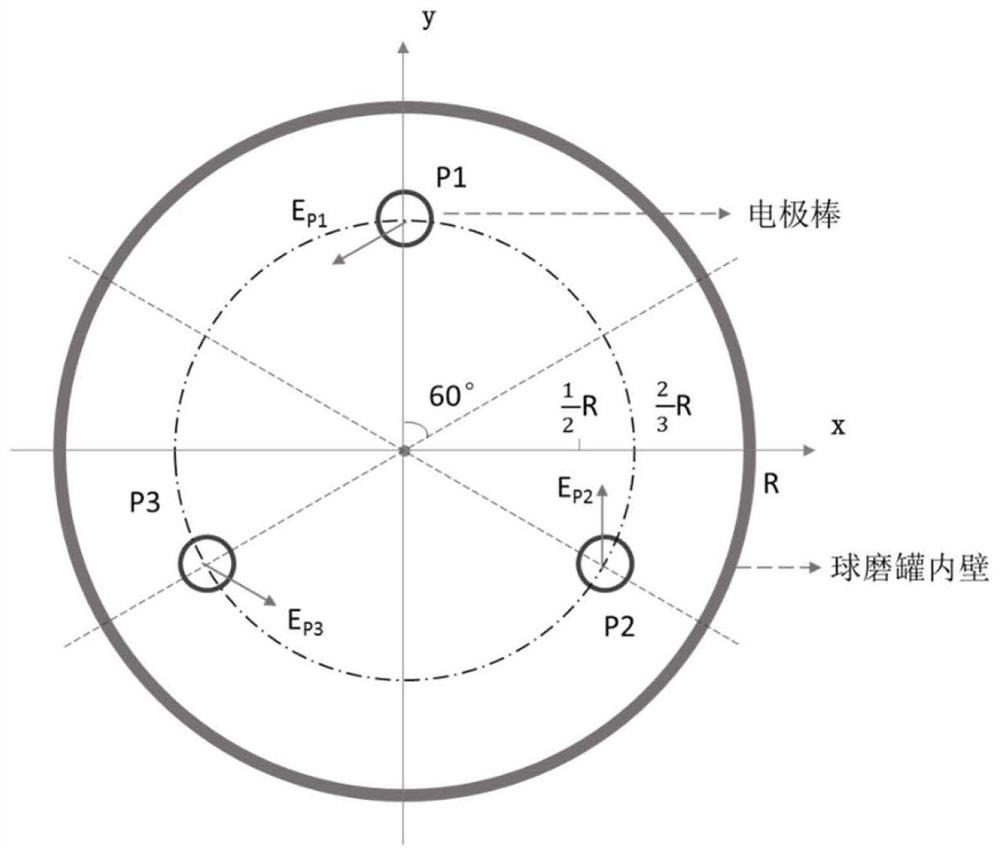

[0021] The three-electrode discharge plasma auxiliary ball grinding in the present invention includes a connecting cylinder 1, a rear cover 2, a front cover 3, and a three-dimensional electrode stick 4, such as figure 1 Indicated. Among them, the material of the connection cylinder 1 is a metal material, the front cover 3, and the material of the rear cover 2 can be polytetrafluoroethylene or high purity ceramics. The conductive battery of the parallel electrode rod 4 simultaneously accesses the plasma power source positive, the entire metal can body access the plasma power supply negative electrode, and the discharge of different electrodes is independent of each other.

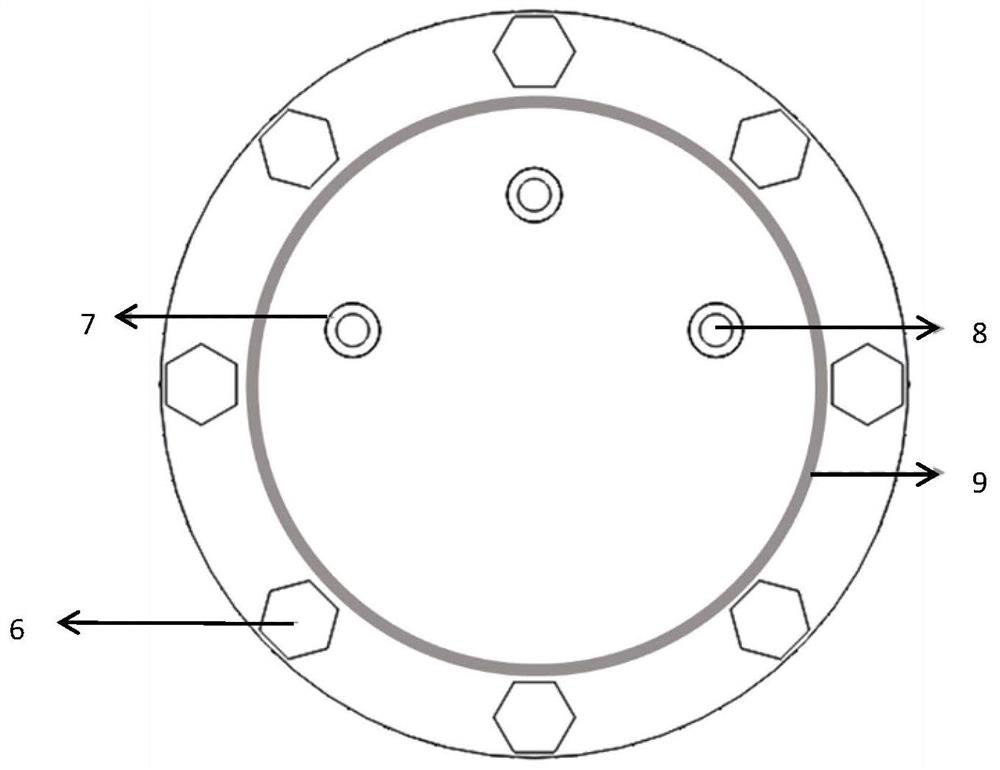

[0022] The front cover 3, the surface of the rear cover 2 and the connection cylinder 1 are provided with an annular sealing groove and a plurality of through holes, and the rear cover is fixed to the connecting cylinder through the bolt 6 of the rear cover, respectively, and The contact between the cover and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com