Fly ash high-efficiency single-stage water washing method and harmless treatment process

A harmless treatment and fly ash technology, applied in the field of fly ash treatment, can solve the problems of large investment and operating costs, many equipment and treatment pools, and low washing efficiency, and achieve low investment costs, high washing efficiency, and low occupation small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The fly ash in this embodiment is selected from the incineration fly ash produced by a waste incineration power plant, and its composition and content are as shown in Example 1 in Table 1;

[0063] The fly ash harmless treatment process in the present embodiment comprises the following steps:

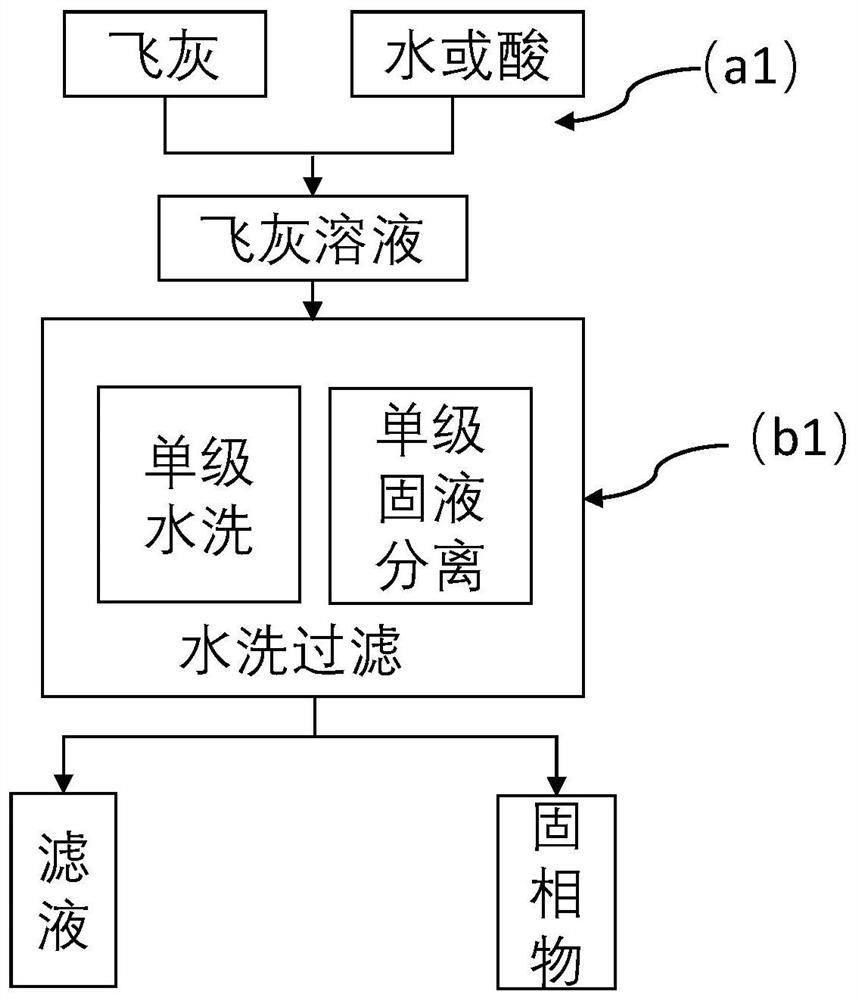

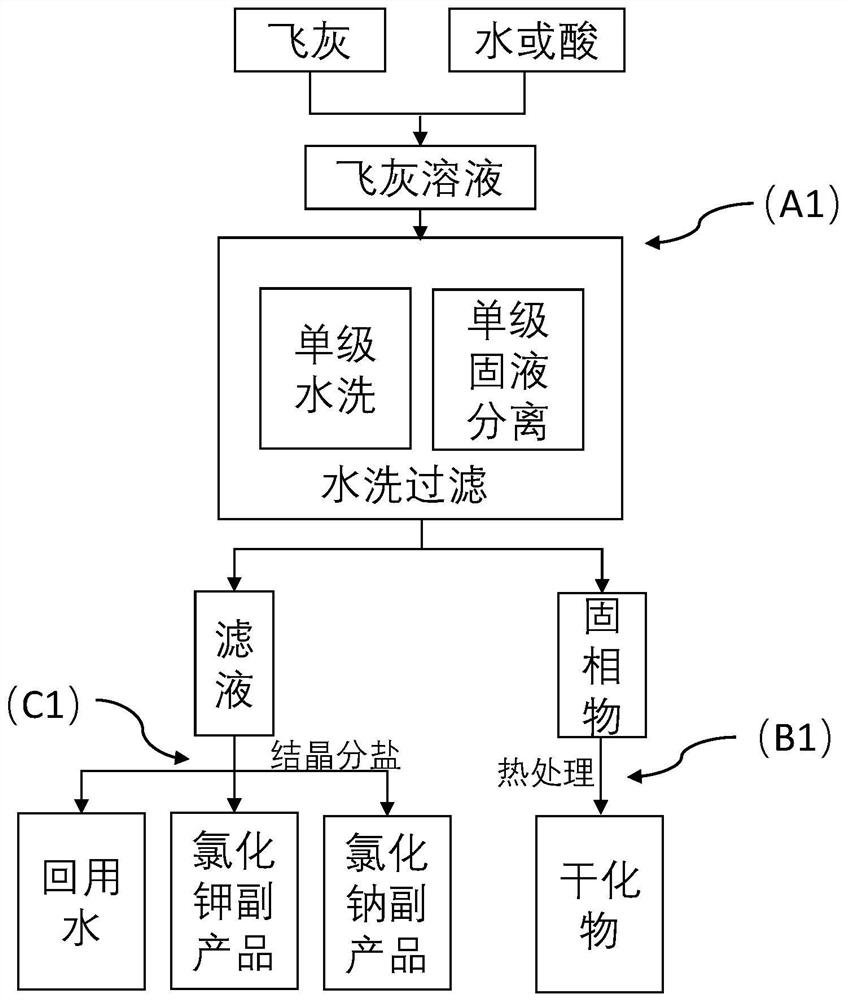

[0064] (A) Single-stage water washing and filtration of fly ash:

[0065] For pretreatment, fly ash and industrial desalted water are added into the mixing tank at a mass ratio of 1:2.5-4.5 and stirred for 15 minutes. Adjust the pH to 7-9;

[0066] Washing and filtering, the prepared fly ash solution is simultaneously subjected to single-stage water washing and single-stage solid-liquid separation to obtain solid phase and filtrate; in the single-stage washing process, the mass ratio of water consumption to original fly ash is 1-2.5 : 1, the control washing time is 1~2.5h; It is known that chloride ion content is 0.5~1wt% in the solid phase thing through testing; The compositio...

Embodiment 2

[0072] The fly ash in this embodiment is selected from the dedusting ash produced by a sintering machine in a steel factory, and its composition and content are as shown in Example 2 in Table 1;

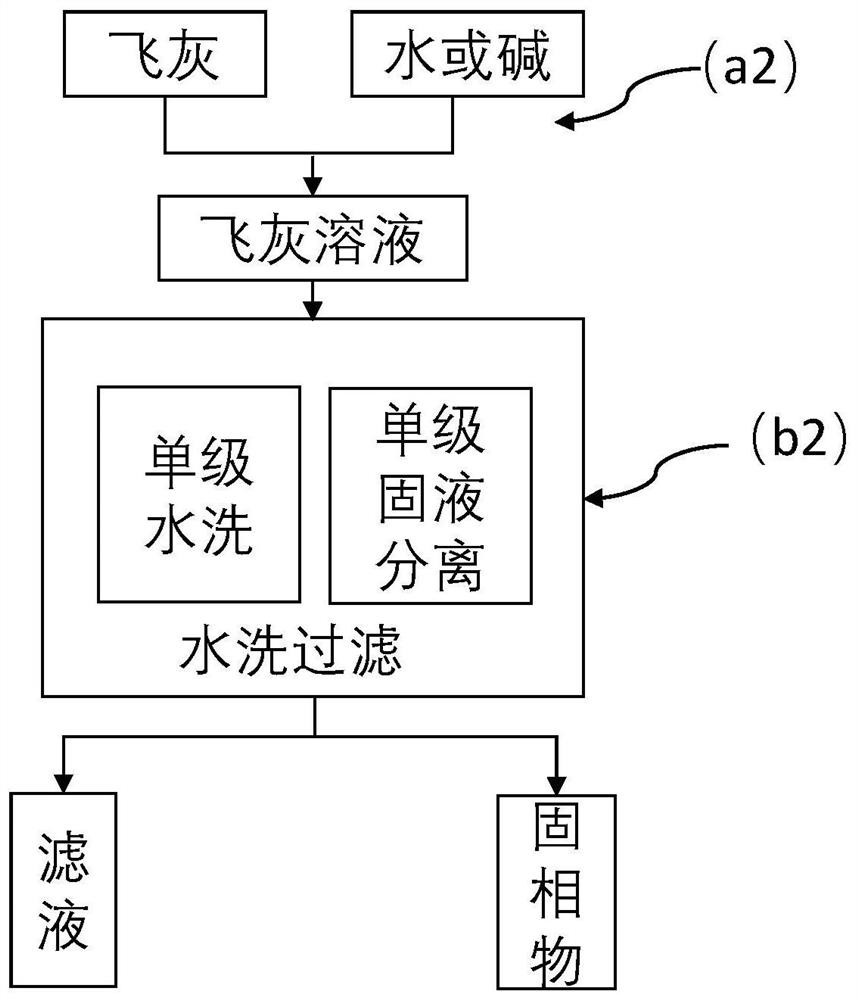

[0073] The fly ash harmless treatment process in the present embodiment comprises the following steps:

[0074] (A) Single-stage water washing and filtration of fly ash:

[0075] For pretreatment, fly ash and industrial desalinated water are added into the mixing tank at a mass ratio of 1:2.5-4.5 and stirred for 10 minutes, and after mixing evenly, a fly ash solution with a solid content of 15-35wt% is obtained; the industrial desalinated water is mixed with hydrochloric acid Adjust the pH to 7-9;

[0076] Wash and filter with water, and carry out single-stage water washing and single-stage solid-liquid separation of the prepared fly ash solution synchronously to obtain solid phase and filtrate; in the single-stage water washing process, the mass ratio of water consumption to origin...

Embodiment 3

[0082] The fly ash in this embodiment is selected from the incineration fly ash produced by a waste incineration power plant, and its composition and content are as shown in Example 3 in Table 1;

[0083] The fly ash harmless treatment process in the present embodiment comprises the following steps:

[0084] (A) Single-stage water washing and filtration of fly ash:

[0085] For pretreatment, fly ash and industrial desalinated water are added to the mixing tank at a mass ratio of 1:2.5-4.5 and stirred for 30 minutes, and after mixing evenly, a fly ash solution with a solid content of 15-35wt% is obtained; the industrial desalinated water is mixed with hydrochloric acid Adjust the pH to 7-9;

[0086] Water washing and filtration, the above prepared fly ash solution is simultaneously subjected to single-stage water washing and single-stage solid-liquid separation to obtain solid phase and filtrate; in the single-stage water washing process, the mass ratio of water consumption to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com