Water pipe purification device with self-repairing function

A purification device and self-repairing technology, which is applied in the direction of pipe components, water pollutants, water treatment sites, etc., can solve the problems of repairing undamaged parts, affecting service life, leaking of sealing rings, etc., so that it is not easy to break and reduces the probability of clogging , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

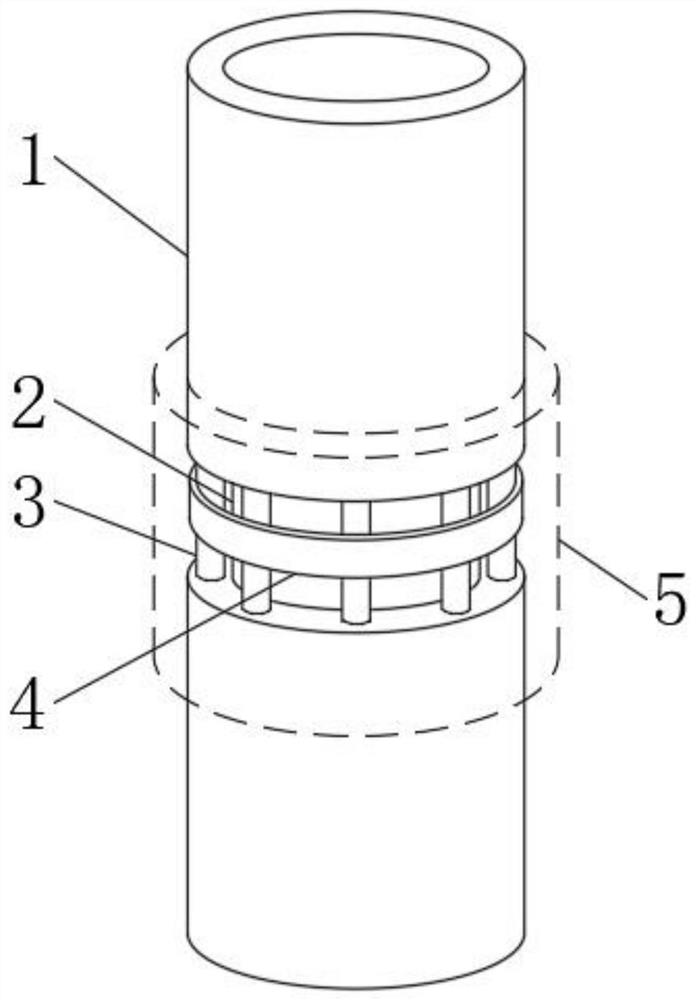

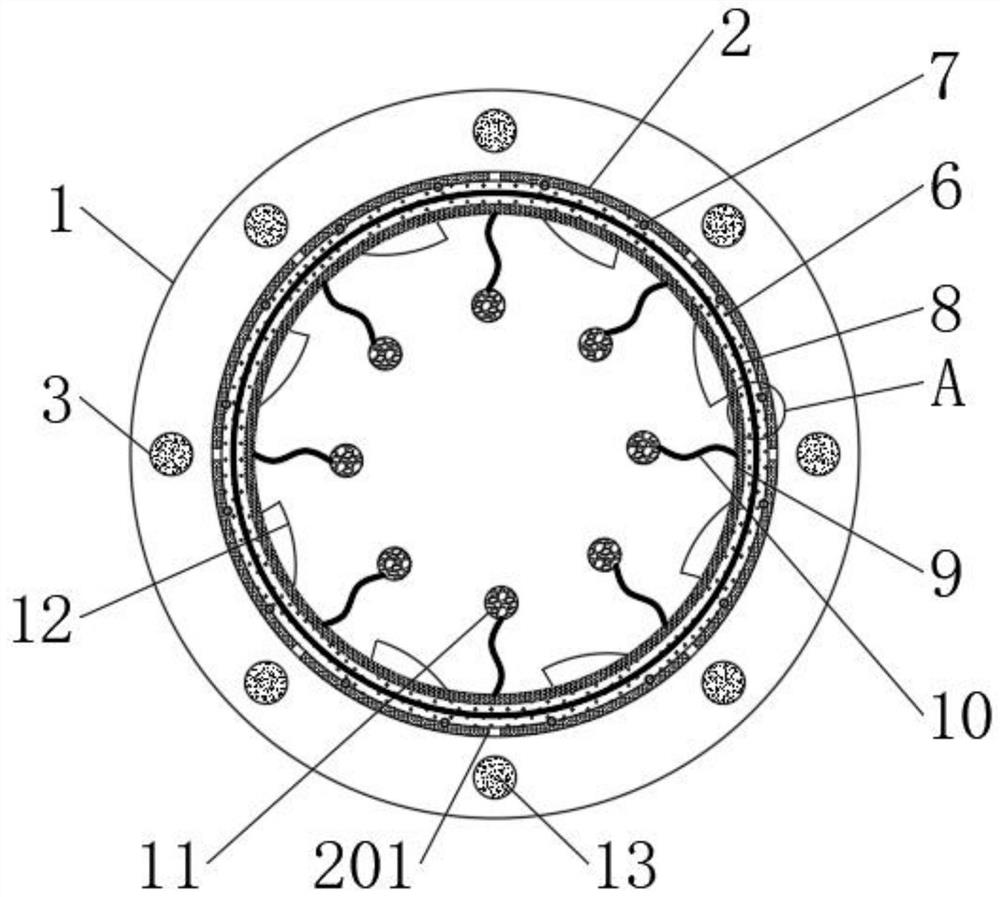

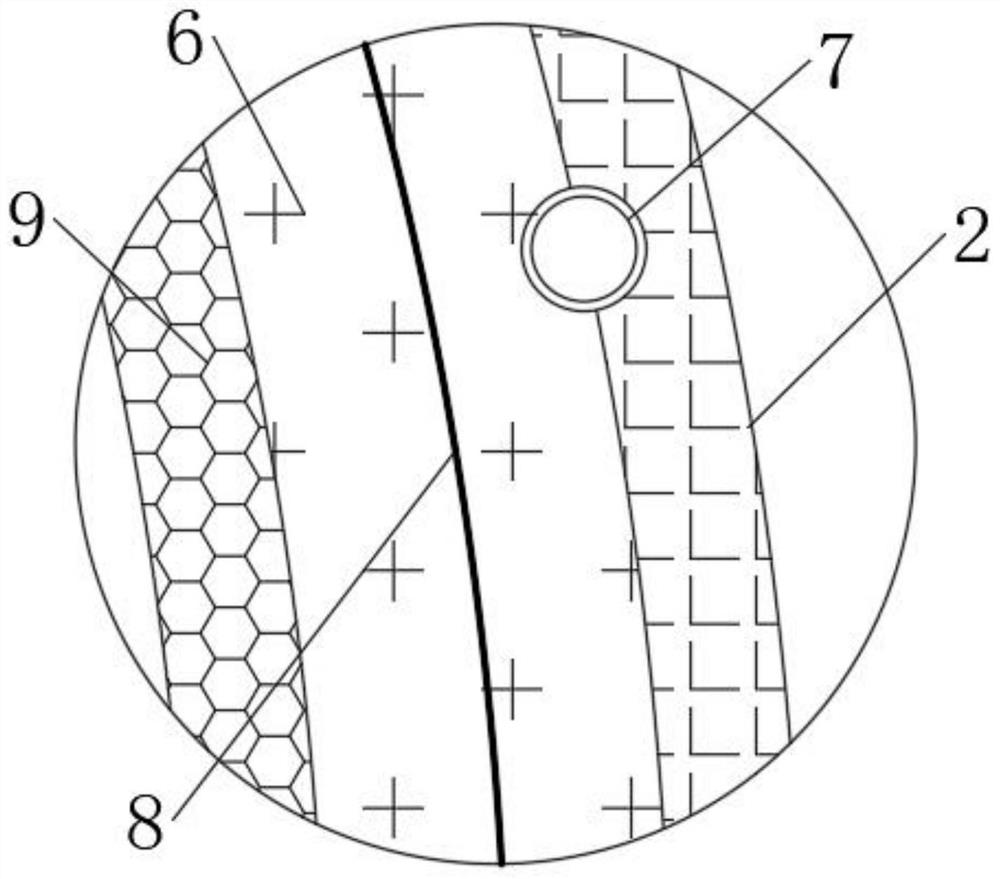

[0043] see Figure 1-2 , a water pipe purification device with self-repairing function, comprising a pair of pre-connection pipes 1, a connecting sealing pipe 2 is fixed between the pair of pre-connecting pipes 1, the connecting sealing pipe 2 is located inside the pre-connecting pipe 1, and the connection between the pair of pre-connecting pipes 1 There are a plurality of evenly distributed space-limiting support tubes 3 fixedly connected between them. The space-limiting support tubes 3 are located outside the connecting sealing tube 2. The outer end of the connecting sealing tube 2 is dug with a plurality of evenly distributed release holes 201. The release holes 201 and The limit support tube 3 communicates, and the inner wall of the connecting sealing tube 2 is fixedly connected with a sealing layer 6, the inner wall of the sealing layer 6 is fixedly connected with an activated carbon adsorption net 9, and the inner wall of the activated carbon adsorption net 9 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com