Zirconia ceramic acne needle and preparation method thereof

A zirconia ceramic, acne technology, applied in medical science, surgery, etc., can solve the problems of skin damage, easy infection, easy to rust, etc., to achieve the effect of good compactness, not easy to hide dirt and dirt, and easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

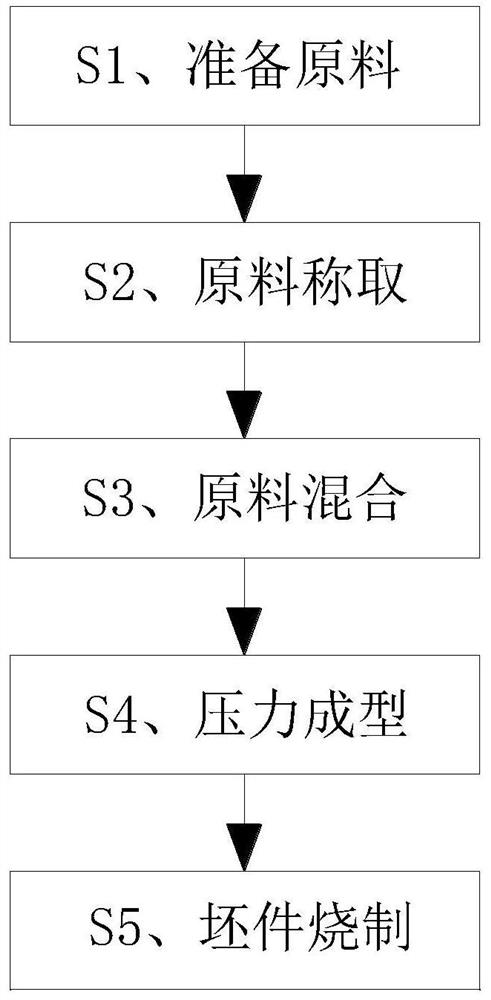

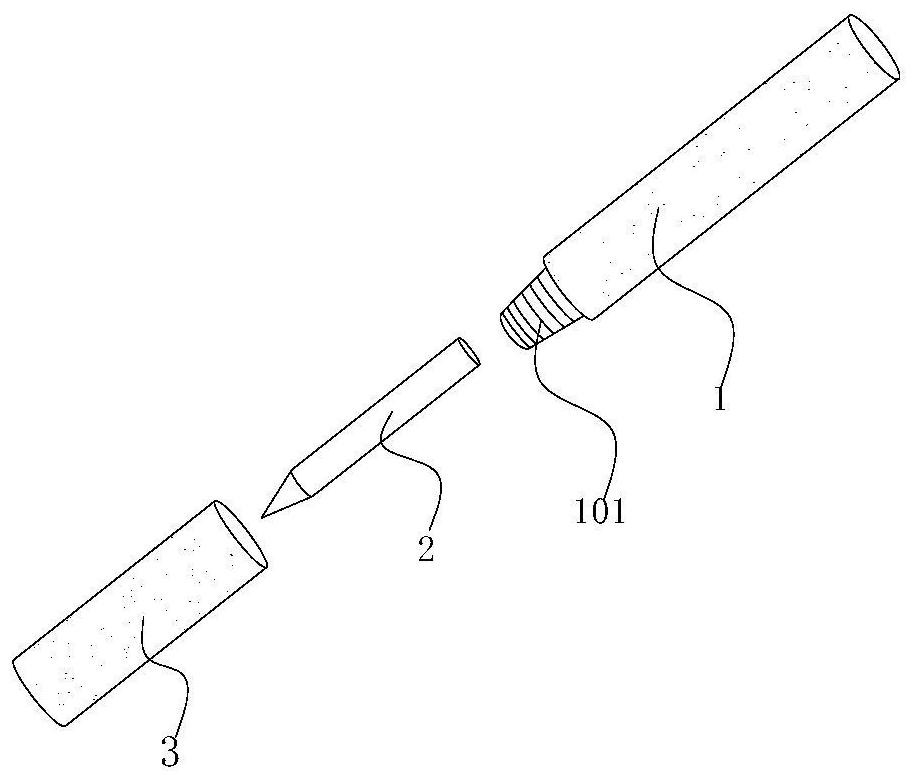

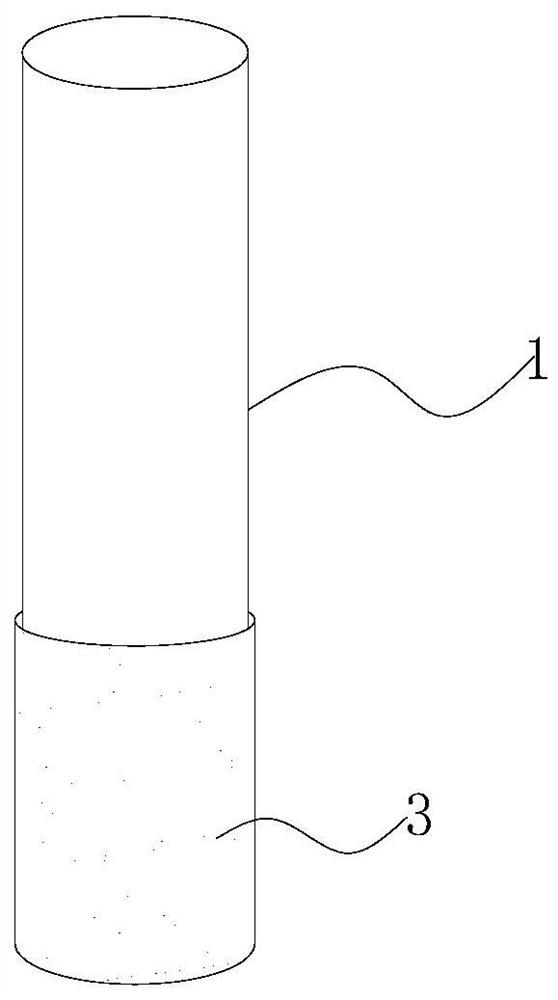

[0027] Example 1: Please refer to Figure 1-3 , the present invention discloses a zirconia ceramic acne needle, comprising a fixed shell 1, the bottom of the fixed shell 1 is provided with a needle cover 101, the bottom of the fixed shell 1 communicates with the needle cover 101, the fixed An acne needle body 2 is movably installed inside the housing 1 , and a connecting sleeve 3 is threadedly provided at the lower end of the fixed housing 1 .

[0028] Specifically, the inside of the needle sheath 101 is engaged with the acne needle body 2 extending to the lower end of the fixed shell 1. The acne needle body 2 is a zirconia ceramic acne needle, and the needle sheath 101 is an oxide needle. Zirconium ceramic needle housing.

[0029] Specifically, the outer sides of the connecting shell 101 and the needle sleeve 101 are provided with external threads, the inside of the connecting sleeve 3 is provided with internal threads, and the lower end of the fixed shell 1 is threaded with...

Embodiment 2

[0037] Example 2: Please refer to Figure 1-3 , the present invention discloses a zirconia ceramic acne needle, comprising a fixed shell 1, the bottom of the fixed shell 1 is provided with a needle cover 101, the bottom of the fixed shell 1 communicates with the needle cover 101, the fixed An acne needle body 2 is movably installed inside the housing 1 , and a connecting sleeve 3 is threadedly provided at the lower end of the fixed housing 1 .

[0038] Specifically, the inside of the needle sheath 101 is engaged with the acne needle body 2 extending to the lower end of the fixed shell 1. The acne needle body 2 is a zirconia ceramic acne needle, and the needle sheath 101 is an oxide needle. Zirconium ceramic needle housing.

[0039] Specifically, the outer sides of the connecting shell 101 and the needle sleeve 101 are provided with external threads, the inside of the connecting sleeve 3 is provided with internal threads, and the lower end of the fixed shell 1 is threaded with...

Embodiment 3

[0047] Example 3: Please refer to Figure 1-3 , the present invention discloses a zirconia ceramic acne needle, comprising a fixed shell 1, the bottom of the fixed shell 1 is provided with a needle cover 101, the bottom of the fixed shell 1 communicates with the needle cover 101, the fixed An acne needle body 2 is movably installed inside the housing 1 , and a connecting sleeve 3 is threadedly provided at the lower end of the fixed housing 1 .

[0048] Specifically, the inside of the needle sheath 101 is engaged with the acne needle body 2 extending to the lower end of the fixed shell 1. The acne needle body 2 is a zirconia ceramic acne needle, and the needle sheath 101 is an oxide needle. Zirconium ceramic needle housing.

[0049] Specifically, the outer sides of the connecting shell 101 and the needle sleeve 101 are provided with external threads, the inside of the connecting sleeve 3 is provided with internal threads, and the lower end of the fixed shell 1 is threaded with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com