Bromotrifluoromethane residual gas recovery device

A technology of trifluoromonobromomethane and recovery device, which is applied in the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of increasing the pressure of the gas storage tank, being unable to extract it for use, and reducing the effective volume of the gas storage tank, etc. To achieve the effect of reducing waste and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

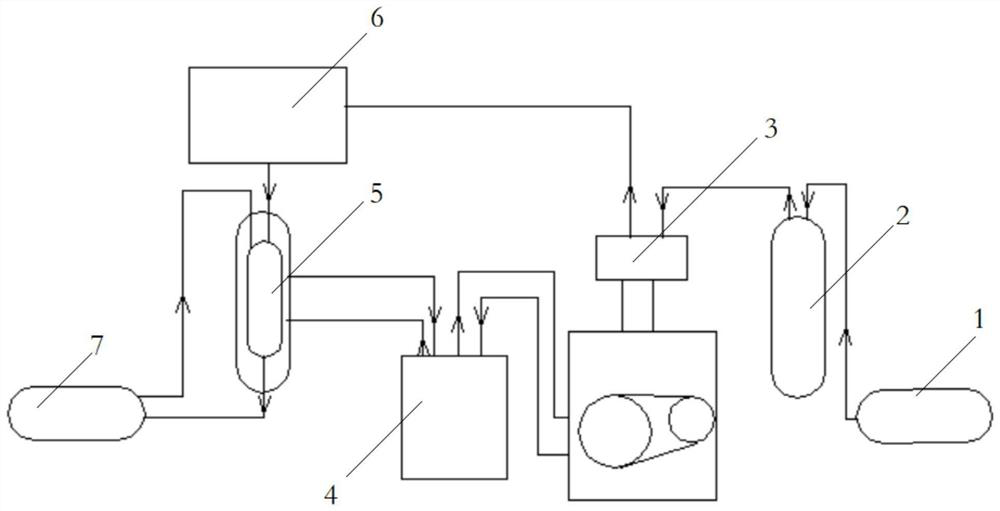

[0017] as attached figure 1 As shown, the present invention provides a bromotrifluoromethane residual gas recovery device, which comprises an intake buffer tank 2, a metal diaphragm compressor 3, a circulating water pool 4, an exhaust buffer tank 5, a spiral plate heat exchanger 6 and Air storage tank 7; the remaining gas bromotrifluoromethane gas tank 1 in the figure is the object to be recovered, and the remaining bromotrifluoromethane in the interior is a liquid and gaseous mixture, and the air storage tank is used to store the bromotrifluoromethane recovery, which Bromotrifluoromethane inside is liquid.

[0018] The inlet and outlet of the intake buffer tank 2 are respectively connected to the residual gas bromotrifluoromethane tank 1 and the inlet of the metal diaphragm compressor 3, and the outlet of the metal diaphragm compressor 3 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com