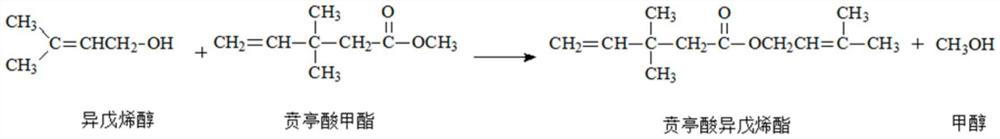

Equipment and method for recycling dimethyl-4-pentenoic acid methyl ester rectification residual liquid

A technology of methyl bentitate and recovery equipment, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of reaction between ester groups and hydroxyl groups. The recovery process is simple and the effect of reducing the cost of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

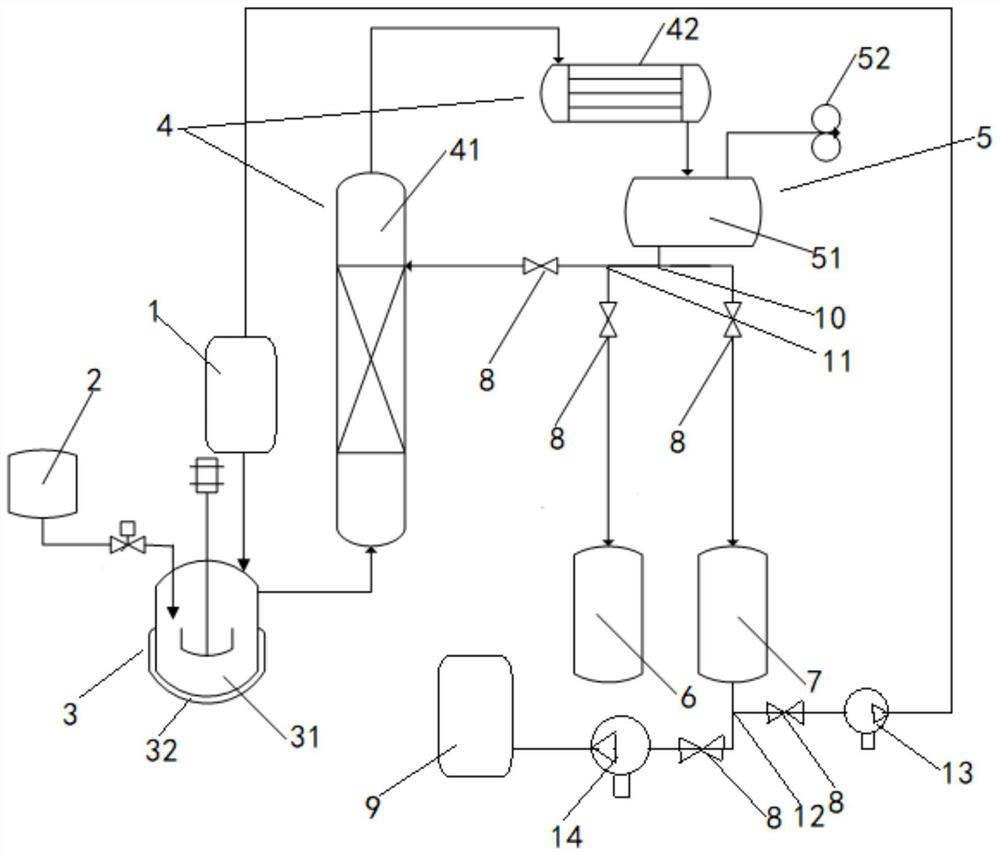

[0032] Utilize above-mentioned recovery equipment to reclaim the method for the rectification raffinate of methyl perineate, comprise the following steps:

[0033] 1) 1560kg (containing 10kmol) of isopentenyl pyreneate remaining in the condensation reactor 1, 320kg (10kmol) of anhydrous methanol, and 5.4kg (0.1kmol) of sodium methylate are put into the transesterification reactor In 3, the material in the transesterification reactor 3 was stirred at normal temperature and pressure for 20min;

[0034] 2) The steam jacket 32 is heated up to 70° C., and the product after the material reaction in the transesterification reactor 3 is condensed through the packed tower 41 and the condenser 42 successively, enters the receiving tank 51 and returns to the packed tower 41 again, and refluxes After reacting for 10 hours, the front fraction enters the receiving tank 51 after being condensed by the packed tower 41 and the condenser 42, and then is introduced into the methanol recovery t...

Embodiment 2

[0038] Utilize above-mentioned recovery equipment to reclaim the method for the rectification raffinate of methyl perineate, comprise the following steps:

[0039] 1) 780kg (containing 5kmol) of isopentenyl pyreneate remaining in the condensation reactor 1, 1600kg (50mol) of anhydrous methanol, and 54kg (1kmol) of sodium methylate are put into the transesterification reactor 3 , the material in the transesterification reactor 3 was stirred at normal temperature and pressure for 30min;

[0040] 2) The steam jacket 32 is heated up to 73° C., and the product after the material reaction in the transesterification reactor 3 is condensed through the packed tower 41 and the condenser 42 successively, enters the receiving tank 51 and returns to the packed tower 41 again, and refluxes After reacting for 11 hours, the front fraction enters the receiving tank 51 after being condensed by the packed tower 41 and the condenser 42, and then is introduced into the methanol recovery tank 6 t...

Embodiment 3

[0044] Utilize above-mentioned recovery equipment to reclaim the method for the rectification raffinate of methyl perineate, comprise the following steps:

[0045] 1) 78kg (containing 0.5kmol) of isopentenyl pyritinate remaining in the condensation reactor 1, 1600kg (50kmol) of anhydrous methanol, and 297kg (5.5kmol) of sodium methylate are put into the transesterification reactor In 3, the material in the transesterification reactor 3 was stirred at normal temperature and pressure for 40min;

[0046] 2) The steam jacket 32 is heated up to 75° C., and the product after the material reaction in the transesterification reactor 3 is condensed through the packed tower 41 and the condenser 42 successively, enters the receiving tank 51 and returns to the packed tower 41 again, and refluxes After reacting for 12 hours, the front fraction enters the receiving tank 51 after being condensed by the packed tower 41 and the condenser 42, and then is introduced into the methanol recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com