Fiber bundle, three-dimensional woven structure, three-dimensional fabric composite material and technological method

A composite material, three-dimensional fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of low fracture toughness, low shear modulus, shear failure and other problems of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Such as figure 2 As shown, the fiber bundle is used to weave a three-dimensional fabric composite material. The fiber bundle is composed of several strands, and several strands are twisted together. The strands are carbon fibers. The model of the carbon fiber is T800H, and the specification of the carbon fiber is 6K. Yarn twists are: 5 twists / m, 10 twists / m, 20 twists / m, 40 twists / m, 60 twists / m.

[0068] In order to meet the final size requirements of the parts during the forming process, the three-dimensional fabric often undergoes large deformation during the forming process, among which shear deformation is the most important form of deformation, and the shear resistance of the three-dimensional fabric is affected by the interweaving points of the yarns. The limitation of the friction force between yarns and the effect of the relative spatial relationship between the yarns, the shear modulus is generally lower in the G12 direction. In order to solve the poor shear...

Embodiment 2

[0076] The structure of the fiber bundle of embodiment two is identical with embodiment one, and difference is: the model of the carbon fiber of embodiment two is CCF800H, and the specification of carbon fiber is 6K, and the single yarn twist of fiber bundle is respectively: 5 twist / m, 10 Twist / m, 20 twist / m, 40 twist / m, 60 twist / m.

[0077] Using the test method identical with embodiment one, the fiber bundle of embodiment two is tested, and test result is as follows Figure 6 It can be seen. The twisted fiber bundle of the present invention is compared with the fiber bundle without twisting treatment, and its elongation at break along with the increase of twist presents the trend that first increases and then decreases, and the shear modulus is at a twist of 20 twists / m reached the maximum. Considering the influence of twisting on the properties of both, it is recommended that the fiber twisting degree be 20 twists / m.

Embodiment 3

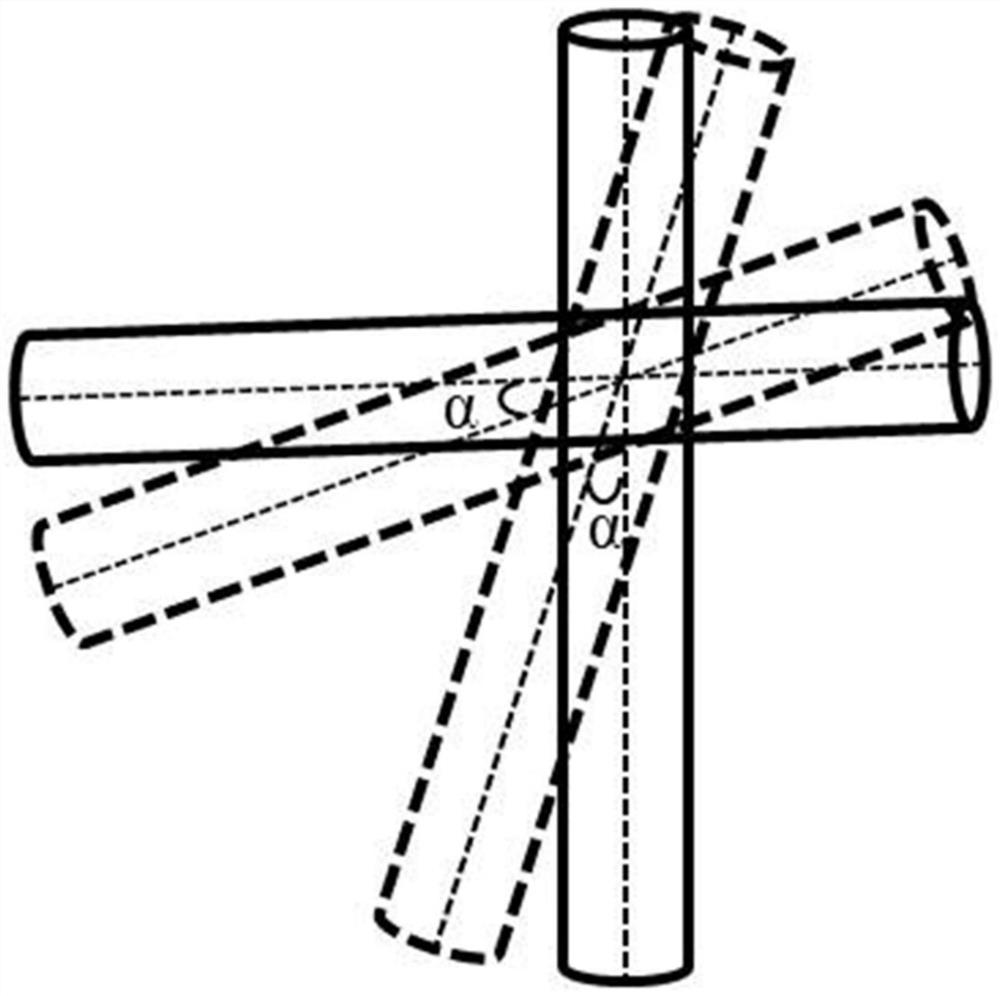

[0079] Such as Figure 7 As shown, according to the relationship curve between G12 and fiber bundle twist angle simulated according to classical laminate theory (the data has been regularized), it can be seen that when the fiber bundle twist angle reaches 45°, the shear modulus of G12 is the largest.

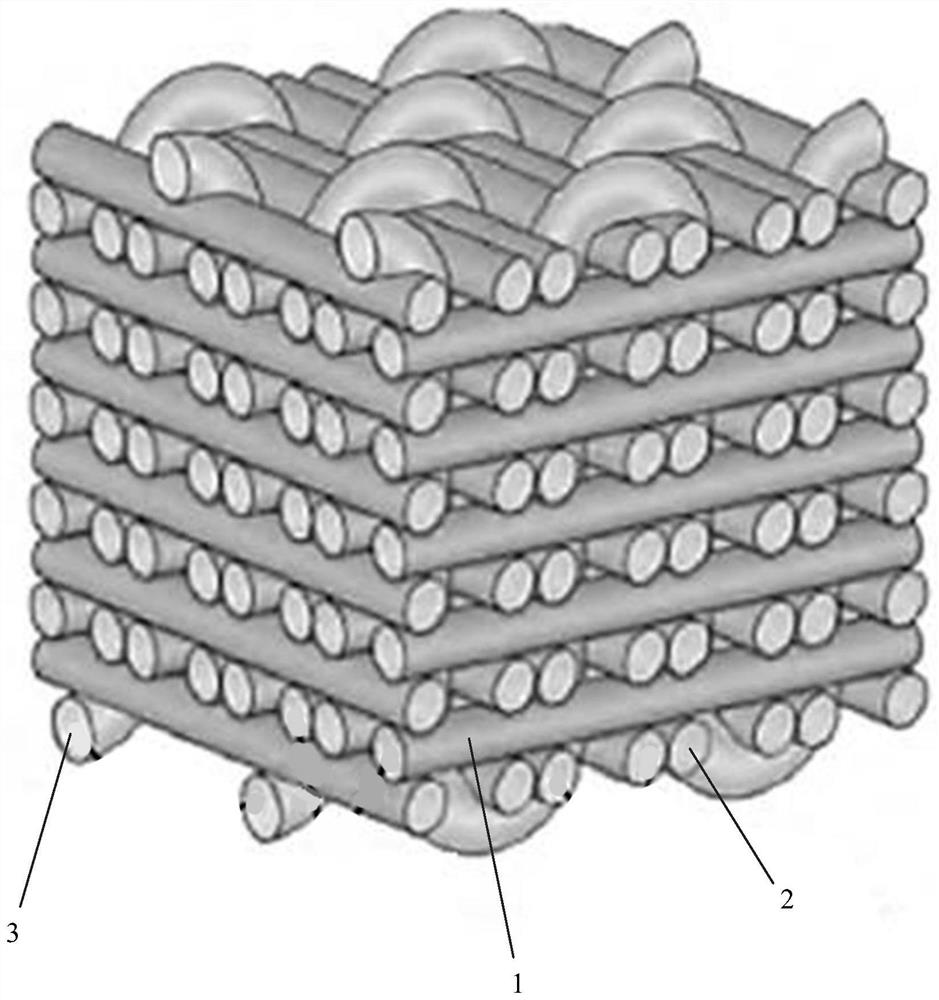

[0080] Such as Figure 8 As shown, the present invention also provides a three-dimensional woven structure. The three-dimensional woven structure is composed of six layers of fiber cloth layers and several Z-direction fibers. Fiber cloth laying, the warp and weft yarns are fiber bundles, the fiber bundles are composed of several strands, and several strands are plyed and twisted. Among them, the strands are carbon fibers, the number of strands is 2, the specifications of the carbon fibers are 6K or 12K, the twist of the fiber bundle is 60 twists / m, and the twist angle of the fiber bundle is less than 23°.

[0081] Specifically, the six layers of fiber cloth layers are respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com