Foamed aluminum sound absorber

A sound-absorbing body and foamed aluminum technology, applied in the field of sound-absorbing materials, can solve the problems of non-recyclable, unprocessable waste, damage to respiratory organs, etc., and achieve the effect of good moth-proof effect, fast construction, and easy assembly and disassembly or handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

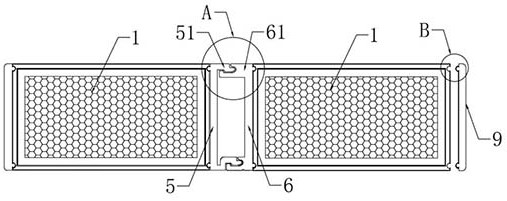

[0024] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

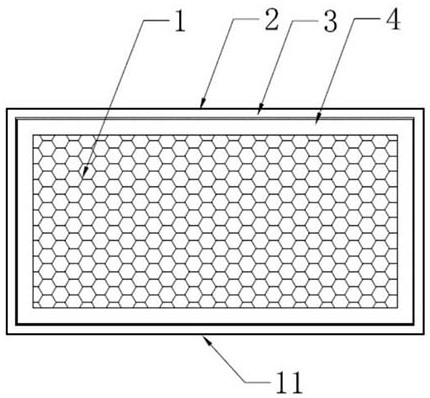

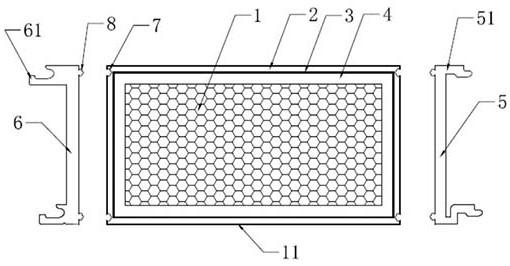

[0025] like Figure 1 to Figure 5 As shown, the present invention preferably implements a foamed aluminum sound absorber, which includes a sound absorber body, and the sound absorber body includes a foamed aluminum block 1. The foamed aluminum block 1 is formed by adding additives to pure aluminum or aluminum alloy, and then undergoing a foaming process. It has the characteristics of sound absorption and reflection, low density, high shock absorption ability, high temperature resistance, etc., which also has the effect of improving the overall support strength, and can also be recycled and rebuilt, which is green and environmentally friendly. The aluminum foam block 1 is wrapped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com