Hybrid pressurized multi-stage filling and hydrogenation device

A hydrogenation device and hydrogen transportation technology, applied in hydrogen technology, equipment loaded into pressure vessels, fluid treatment, etc. Insufficient hydrogen storage on-board under hydrogen pressure and other problems, to achieve the effect of improving utilization efficiency and flexibility, improving hydrogenation flexibility and reliability, and improving operating economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

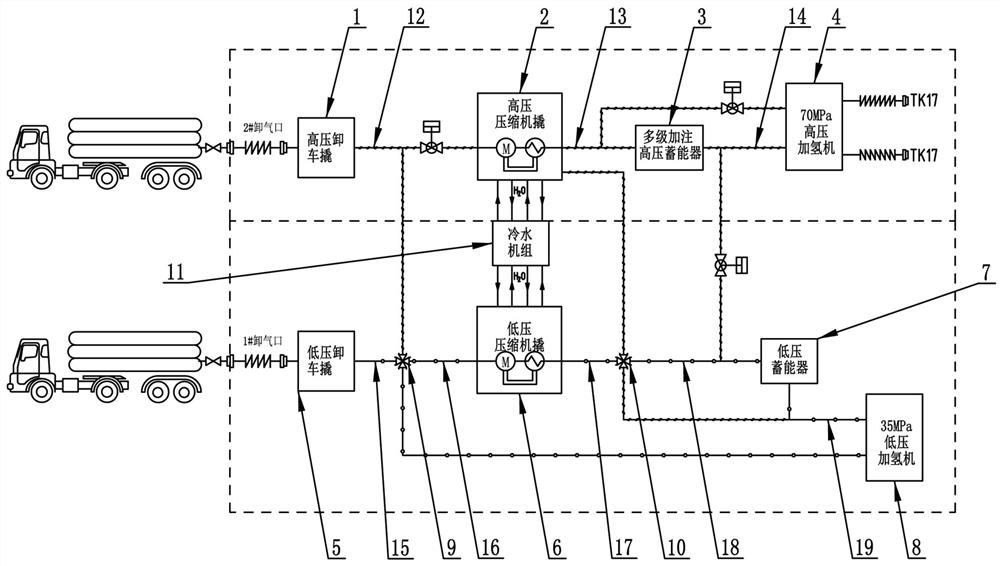

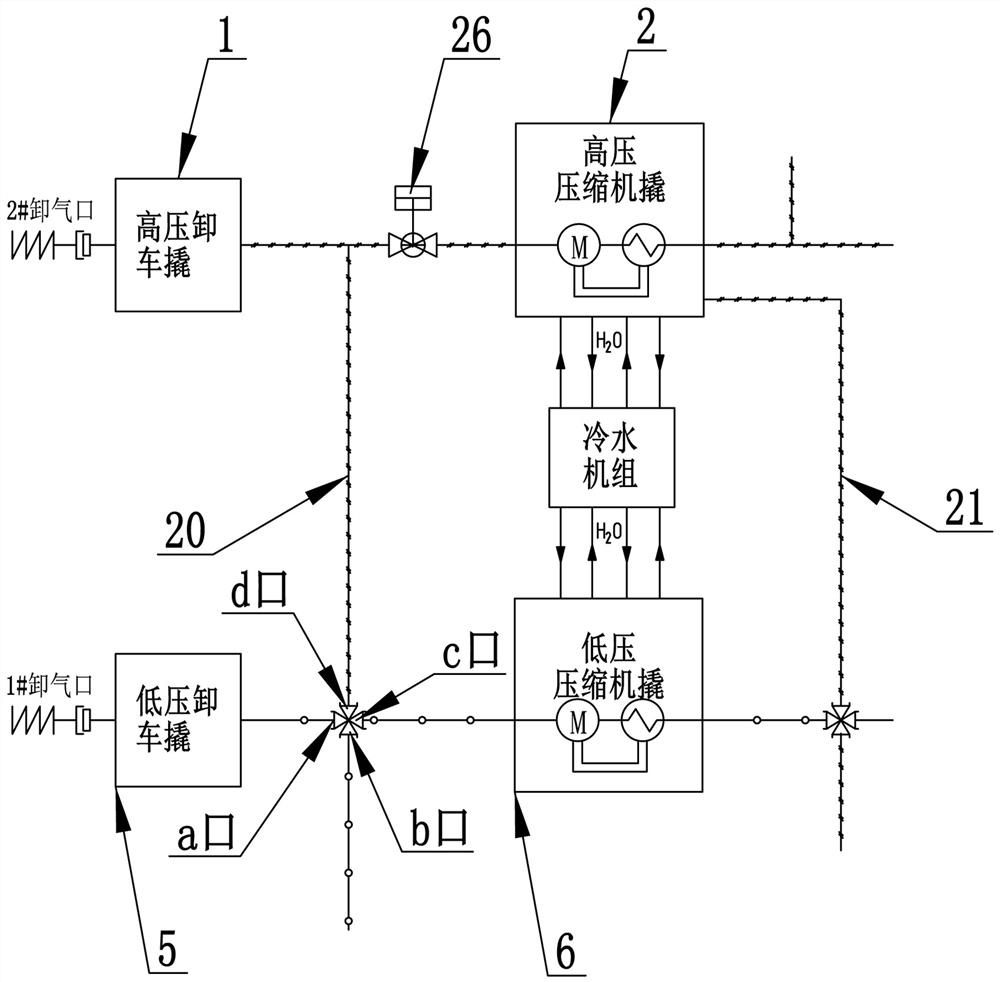

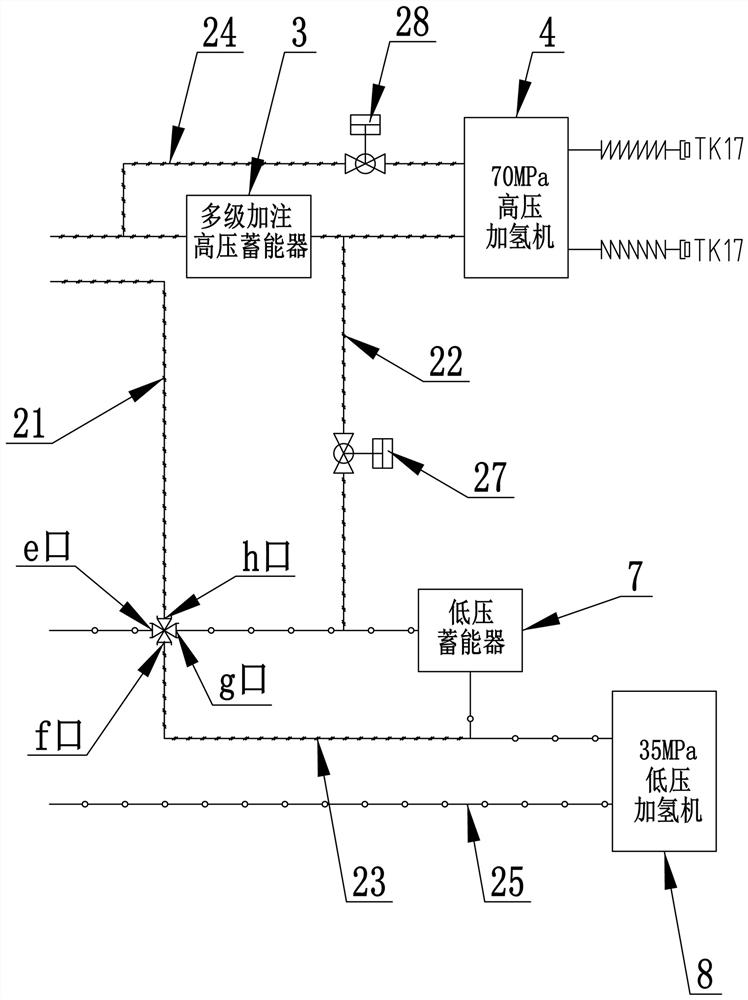

[0029] Such as figure 1 , figure 2 and image 3 As shown, a hybrid pressurized multi-stage filling hydrogenation device described in this embodiment includes the following components: high-pressure unloading skid 1, high-pressure compressor skid 2, multi-stage filling high-pressure accumulator 3, 70MPa High-pressure hydrogenation machine 4, low-pressure unloading skid 5, low-pressure compressor skid 6, low-pressure accumulator 7, 35MPa low-pressure hydrogenation machine 8, the first four with four connection ports a, b, c, and d A through valve 9, a second four-way valve 10 with four connection ports e, f, g, and h, and a chiller 11 for cooling the high-pressure compressor skid 2 and the low-pressure compressor skid 6.

[0030] The outlet of the high-pressure unloading skid 1 communicates with the inlet of the high-pressure compressor skid 2 through the first hydrogen pipeline 12, and the outlet of the high-pressure compressor skid 2 communicates with the multi-stage fillin...

Embodiment 2

[0046] This embodiment is a detailed description of the structure of the multi-stage filling high-pressure accumulator 3 on the basis of the first embodiment. The multi-stage filling high-pressure accumulator 3 is a two-stage filling structure composed of a sequence control panel, a number of high-pressure hydrogen storage bottles 44 arranged in parallel, and a number of medium-pressure hydrogen storage bottles 42 arranged in parallel. The ratio of the number of 44 to the number of medium-pressure hydrogen storage bottles 42 is 1:2.

[0047] Such as Figure 5 As shown, in this embodiment, each medium-pressure hydrogen storage bottle 42 forms a medium-pressure hydrogen storage bottle group, each high-pressure hydrogen storage bottle 44 forms a high-pressure hydrogen storage bottle group, and the high-pressure hydrogen storage bottle group is arranged above the medium-pressure hydrogen storage bottle group .

[0048] Such as Figure 4 As shown, the sequence control panel is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com