248 nm thick film photoresist resin as well as preparation method and application thereof

A photoresist and resin technology, which is applied in the field of 248nm thick film photoresist resin and its preparation, can solve the problems of insufficient heat resistance, inability to suppress fluctuation phenomenon, poor film peelability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

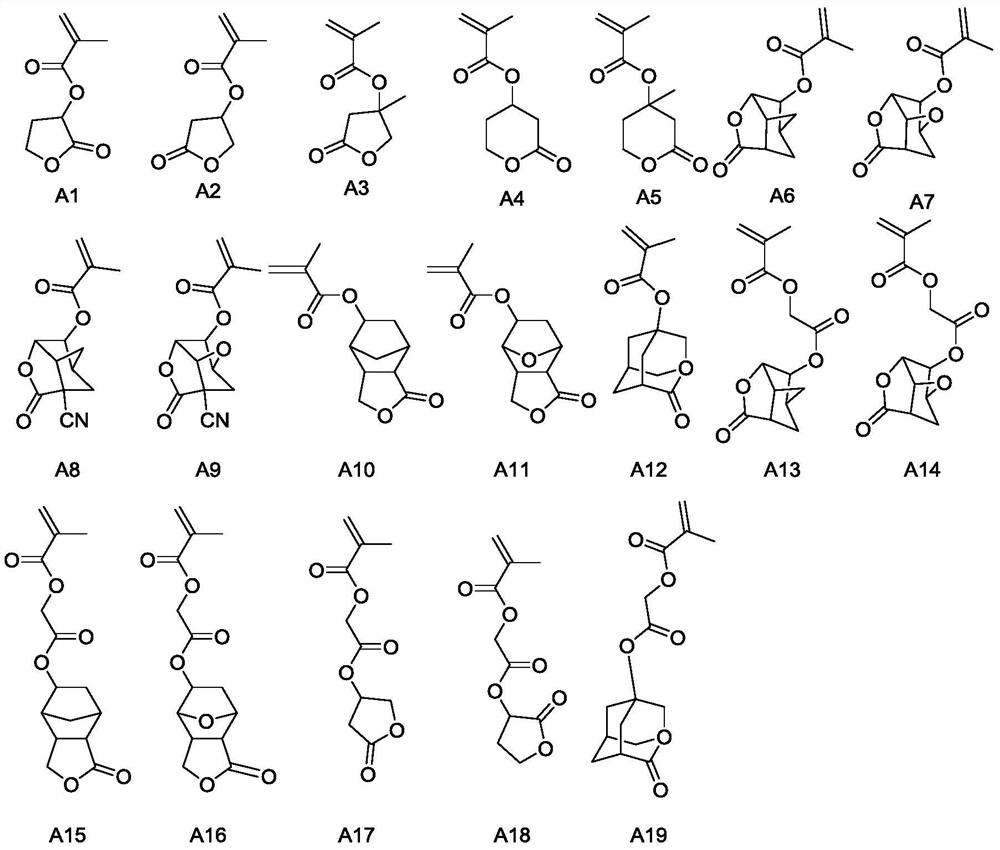

[0172] Preparation of resin

[0173] Resins 1-15 used in Examples or Comparative Examples were prepared according to the following methods. The individual monomers used are as follows:

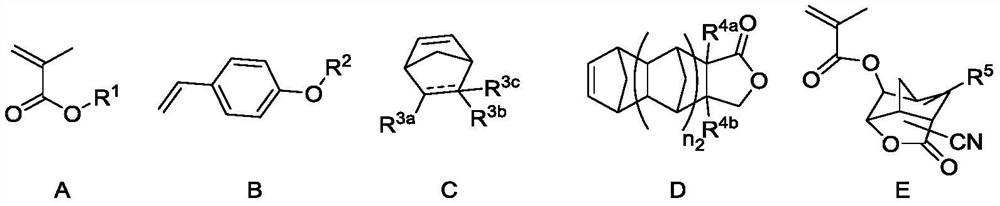

[0174] Monomer A:

[0175]

[0176] Monomer B:

[0177]

[0178] Monomer C:

[0179]

[0180] Monomer D:

[0181]

[0182] Monomer E:

[0183]

[0184] Step 1: Add the amount of monomers according to A-E in Table 1 into a reaction kettle filled with nitrogen, then add 100g of ethyl acetate into the reaction kettle, stir evenly, raise the temperature of the reaction kettle to 77°C, and then add to the reaction kettle again A mixture of ethyl acetate (20 g) and benzoyl peroxide (2 g) was added dropwise to the kettle, and the addition was completed in 10 minutes. React at 77°C for 7 hours, stop the reaction, and cool the temperature of the reaction solution to room temperature;

[0185] Step 2: After the reaction solution was cooled to room temperature, methanol (1000 g) was...

Embodiment 1-10 and comparative example 1-10

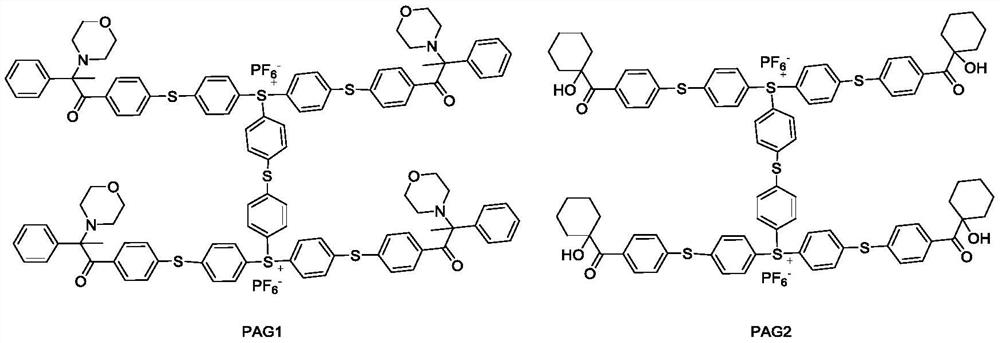

[0193] Photoacid Generator:

[0194] Add the ingredients according to Table 2 into a new clean 100mL glass bottle. At room temperature, the mixture was shaken in the bottle for 24 hours to fully dissolve it, and then the photoresist solution was filtered through 0.22 micron and 0.02 micron filters successively to obtain a photoresist composition.

[0195] Table 2

[0196] Example number Resin serial number photoacid generator solvent Resin weight PAG weight solvent weight 1 1 PAG1 Cyclohexanone 25g 5g 70g 2 2 PAG2 ethyl acetate 30g 0.60g 69.40g 3 3 PAG2 Ethylene glycol monomethyl ether 10g 5g 85g 4 4 PAG1 Cyclohexanone 35g 5g 60g 5 5 PAG2 Ethylene glycol monomethyl ether 45g 5g 50g 6 6 PAG1 ethyl acetate 25g 5g 70g 7 7 PAG2 Dipropylene glycol monomethyl ether 30g 0.60g 69.40g 8 8 PAG1 Dipropylene glycol monomethyl ether 20g 3g 77g 9 9 PAG2 ethyl ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com