Solar silicon wafer light attenuation resisting device and anti-light-decay processing method

A technology of silicon wafers and solar energy, applied in photovoltaic power generation, electrical components, climate sustainability, etc., can solve problems such as extrusion collision, misalignment, and low position accuracy of the limit head, so as to improve applicability and limit position Accuracy, avoiding the effect of large offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

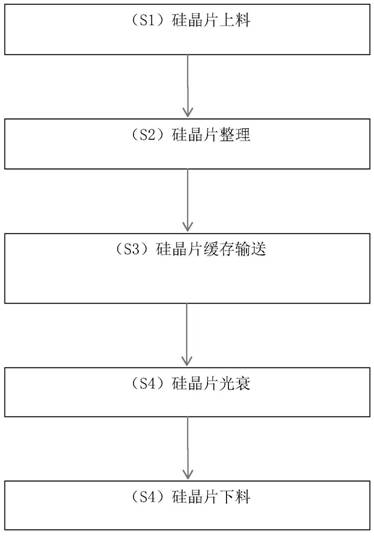

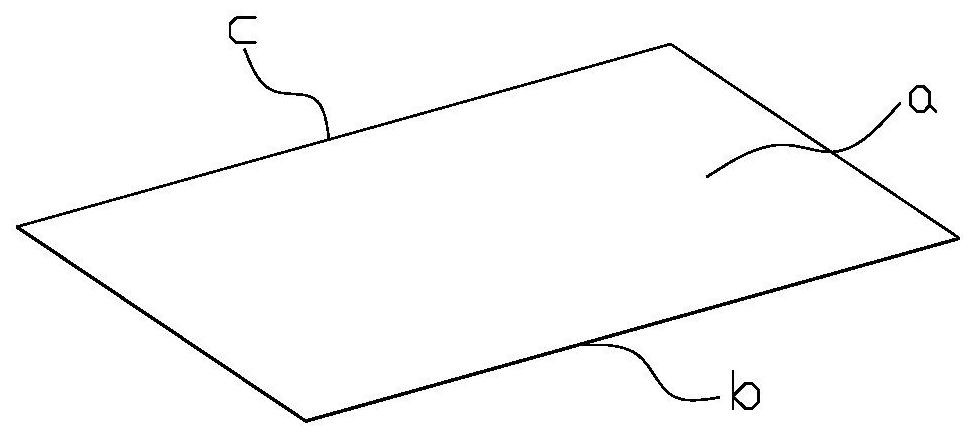

[0039] Such as Figure 1-15 A solar silicon wafer anti-light attenuation equipment shown, the equipment includes a workbench and a silicon wafer feeding device 1 fixed on the workbench, a silicon wafer conveying device 2, a light attenuation furnace 3, a feeding device 4 and fixtures The reflow device 5 is connected to the silicon wafer feeding device 1 and the unloading device 4; the input end and the output end of the silicon wafer feeding device 1 are respectively connected with the silicon wafer feeding port and the silicon wafer conveying device 2 input end; the silicon wafer conveying device 2. The output end is connected to the feed port of the light decay furnace, and the discharge port of the light decay furnace is connected to the feed end of the unloading device; the discharge end of the unloading device is connected to the unloading station; the silicon wafer feeding device 1 is used for The loading of solar silicon wafers; the silicon wafer conveying device 2 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com