High-precision and high-thermal-stability optical splicing focal plane applied to space camera

A high thermal stability, optical splicing technology, applied in the field of space optical remote sensing, can solve problems such as unfavorable image synthesis, dark current noise increase, thermal expansion deformation of structural parts, etc., to reduce the temperature fluctuation range, reduce dark current noise, Relieve the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

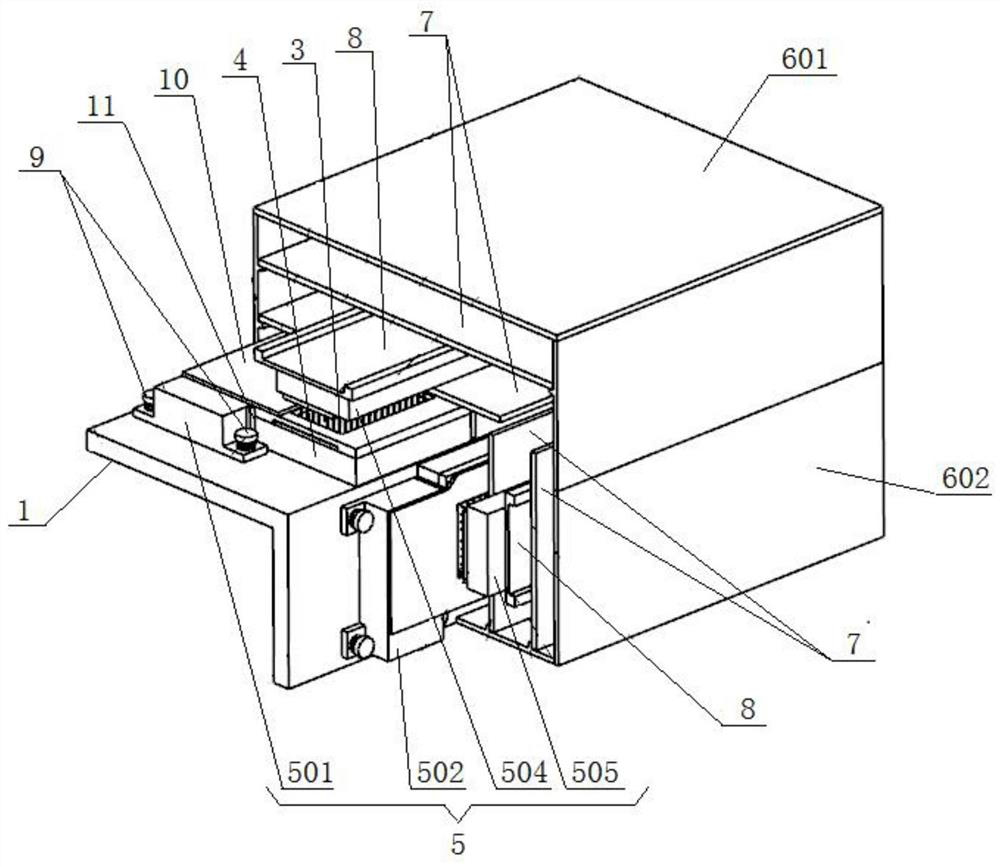

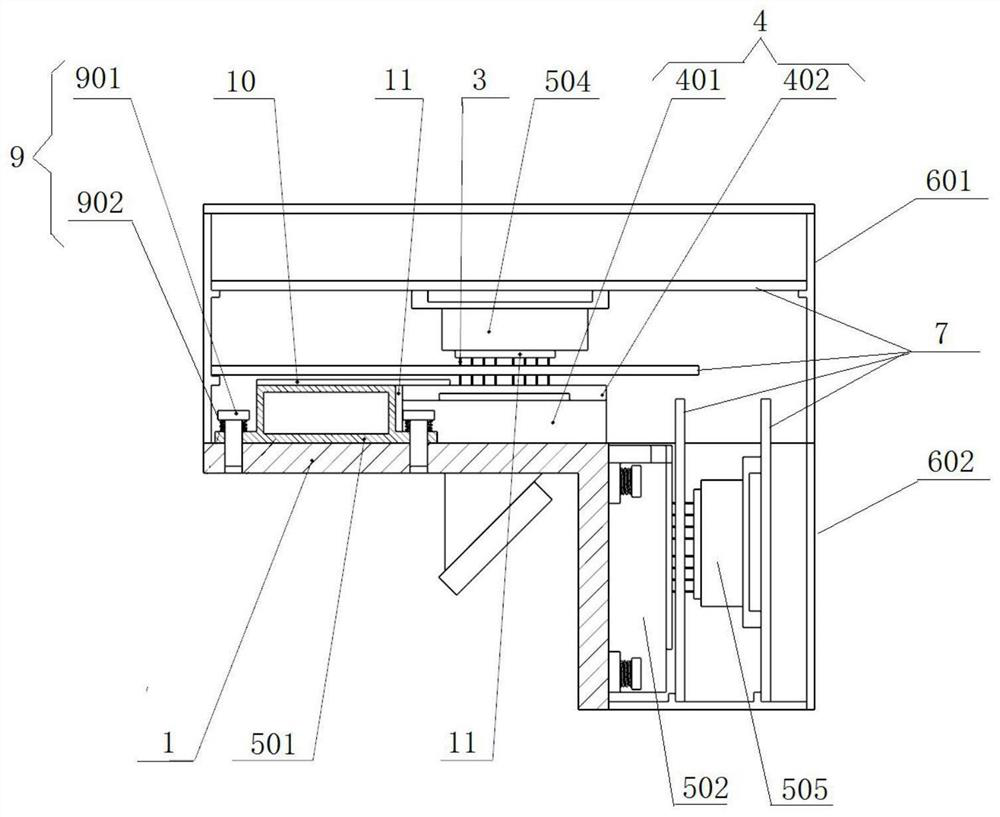

[0051] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0052] see Figure 1-6 shown;

[0053] Invented a high-precision, high-thermal-stability optical stitching focal plane applied to space cameras, including:

[0054] A substrate 1, a plurality of beam splitter assemblies 2 are installed on one side, and a plurality of image sensors 3 are installed on the other side through a holder assembly 4;

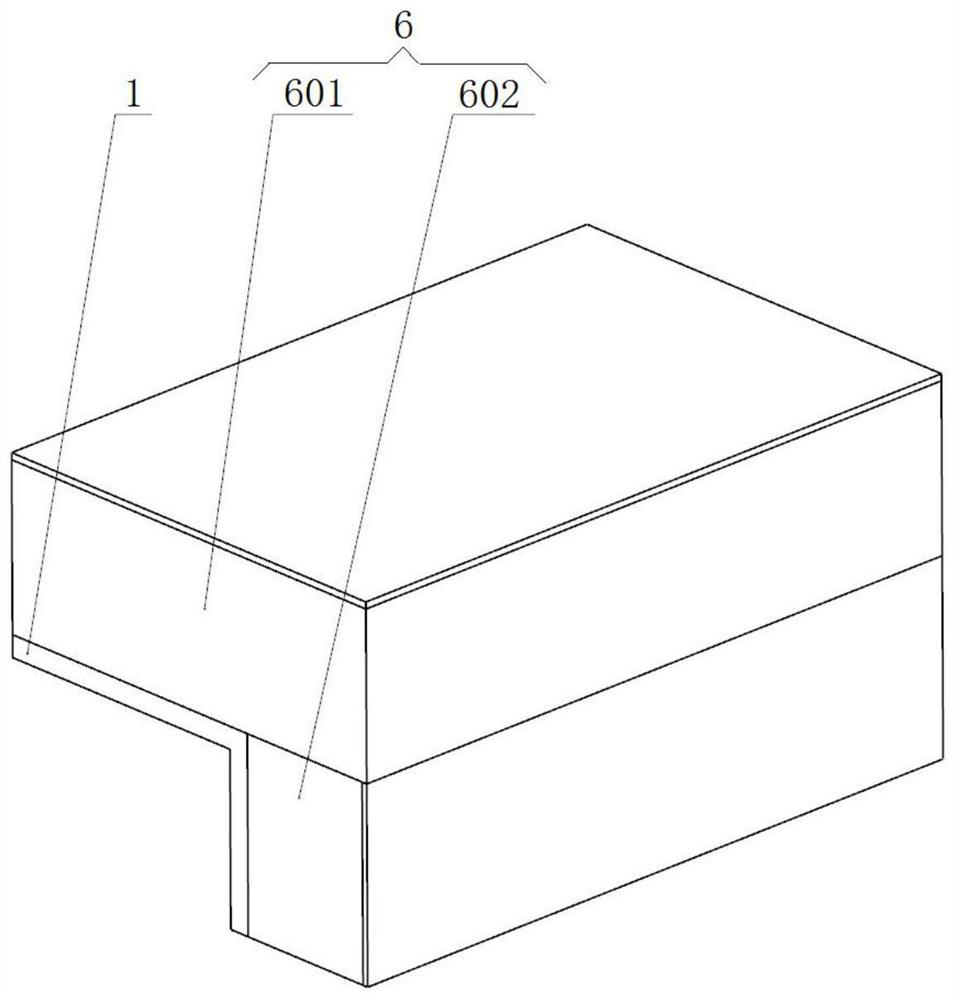

[0055] A box body 6, which is covered outside the image sensor 3, and the box body 6 is fixedly connected to the substrate 1;

[0056] A phase-change energy storage box group 5, which includes a first phase-change energy storage box group installed on the substrate 1 and a second phase-change energy storage box group installed on the box body 6;

[0057] The first phase change energy storage box group i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com