Dual-network adhesive for crosslinking of transglutaminase and preparation method of dual-network adhesive

A transglutaminase and adhesive technology, which is applied in the field of biomedical tissue engineering materials, can solve the problems of lack of adhesion ability of tissue surface acting groups, complicated and difficult to implement synthetic modification methods, complicated synthetic methods, etc. Low, simple synthetic method, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

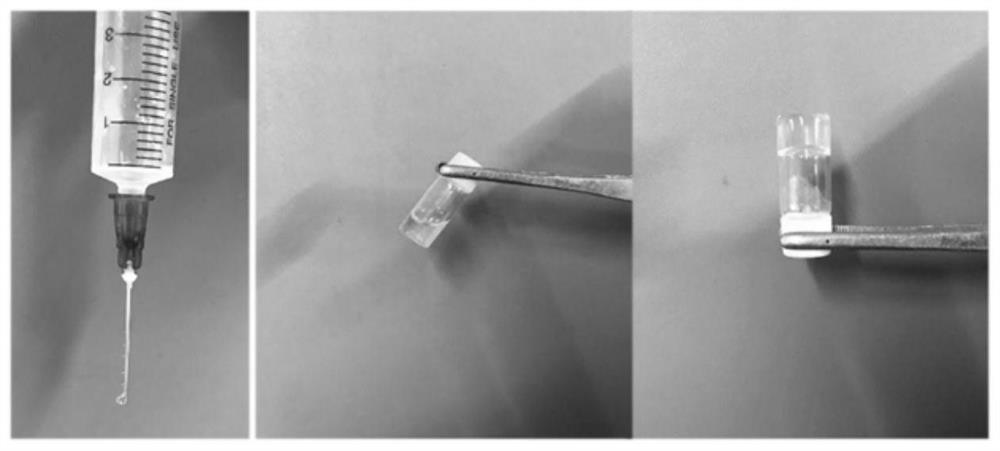

Method used

Image

Examples

Embodiment example 1

[0044] The dextran powder that takes by weighing 2g number-average molecular weight 40000 is dissolved in 160ml deionized water, and is stirred at room temperature until fully dissolved; The NaIO that takes by weighing 1.9g Powder is dissolved in 40ml deionized water, is stirred until fully dissolved; NaIO solution is added to glucose In the polysaccharide solution, keep away from light, and keep stirring at a stirring rate of 200rpm for 24h; add 0.95g of diethylene glycol to the mixed solution of NaIO4 and dextran, and stir at room temperature for 1h; after the reaction is completed, dialyze in deionized water for 72h, -40 Dextran aldehyde with an oxidation degree of 50% was obtained after freeze-drying at ℃. Dissolve 11 mg of dextran aldehyde sample in 100 μl of phosphate buffer solution with pH=7.2-7.4, and stir until completely dissolved.

[0045] Weigh 1.5g of gelatin powder, dissolve it in 5ml of phosphate buffer solution with pH=7.2-7.4, let it stand in a water bath at ...

Embodiment example 2

[0048] The dextran powder that takes by weighing 2g number-average molecular weight 40000 is dissolved in 160ml deionized water, and is stirred at room temperature until fully dissolved; The NaIO that takes by weighing 1.9g Powder is dissolved in 40ml deionized water, is stirred until fully dissolved; NaIO solution is added to glucose In the polysaccharide solution, keep away from light, and keep stirring at a stirring rate of 200rpm for 24h; add 0.95g of diethylene glycol to the mixed solution of NaIO4 and dextran, and stir at room temperature for 1h; after the reaction is completed, dialyze in deionized water for 72h, -40 Dextran aldehyde with an oxidation degree of 50% was obtained after freeze-drying at ℃. Dissolve 11 mg of dextran aldehyde sample in 100 μl of phosphate buffer solution with pH=7.2-7.4, and stir until completely dissolved.

[0049] Weigh 1.5g of gelatin powder, dissolve it in 5ml of phosphate buffer solution with pH=7.2-7.4, let it stand in a water bath at ...

Embodiment example 3

[0052] The dextran powder that takes by weighing 2g number-average molecular weight 40000 is dissolved in 160ml deionized water, and is stirred at room temperature until fully dissolved; The NaIO that takes by weighing 1.9g Powder is dissolved in 40ml deionized water, is stirred until fully dissolved; NaIO solution is added to glucose In the polysaccharide solution, keep away from light, and keep stirring at a stirring rate of 200rpm for 24h; add 0.95g of diethylene glycol to the mixed solution of NaIO4 and dextran, and stir at room temperature for 1h; after the reaction is completed, dialyze in deionized water for 72h, -40 Dextran aldehyde with an oxidation degree of 50% was obtained after freeze-drying at ℃. Dissolve 11 mg of dextran aldehyde sample in 100 μl of phosphate buffer solution with pH=7.2-7.4, and stir until completely dissolved.

[0053] Weigh 1.5g of gelatin powder, dissolve it in 5ml of phosphate buffer solution with pH=7.2-7.4, let it stand in a water bath at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

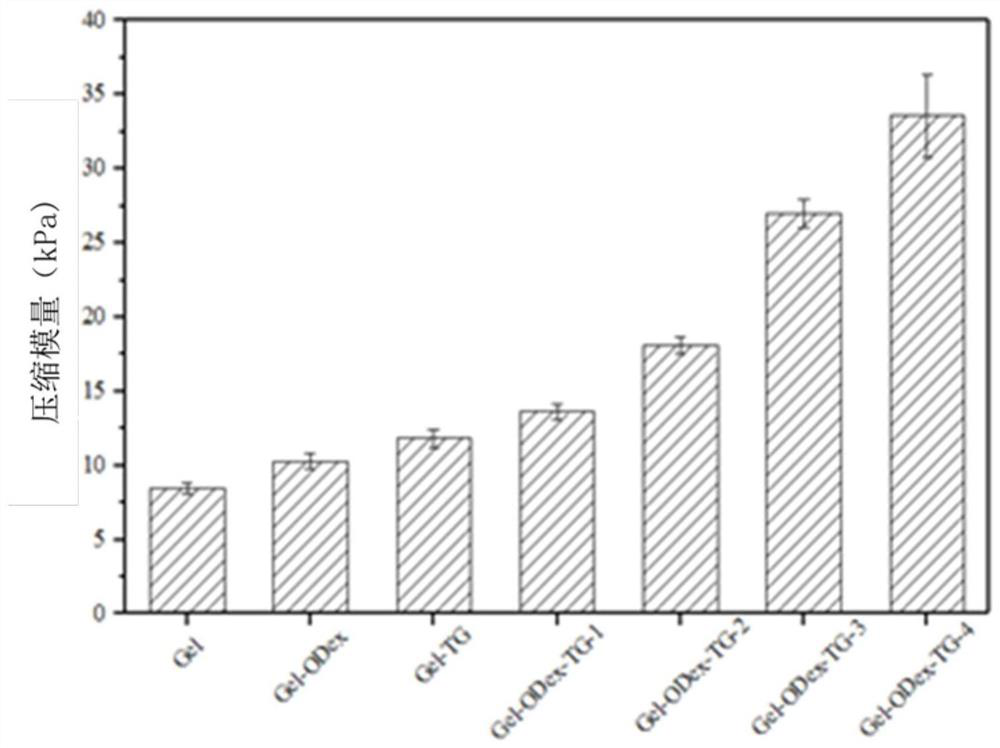

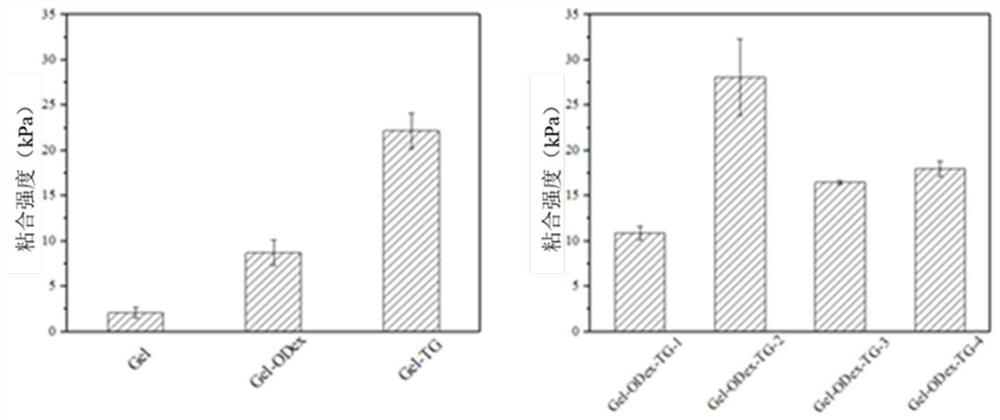

| compressive modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com