Coating plastic spraying equipment

An equipment and coating technology, applied in the direction of coating, spray booth, spray device, etc., can solve the problems of working environment pollution, plastic powder heating, uneven plastic powder treatment, etc., to reduce production costs, uniform plastic powder particles, The effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

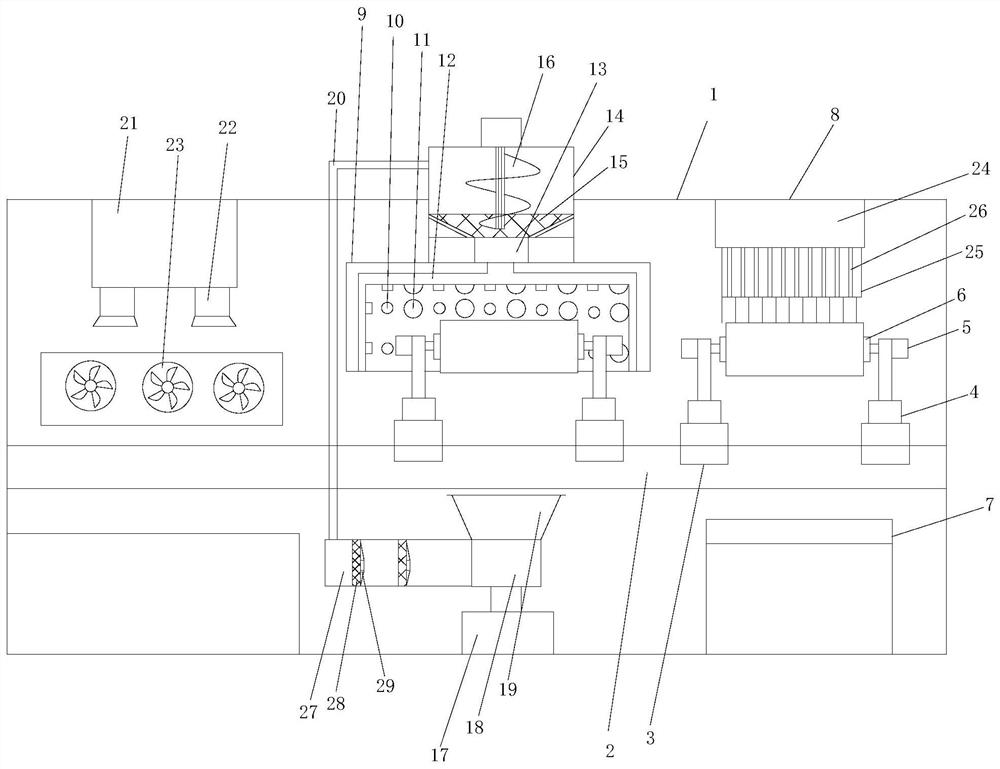

[0015] see figure 1 , the present invention is a coating spraying equipment, including a spraying case 1, a travel guide 2, a travel slider group 3, a lifting mechanical arm 4, a rotating motor 5, a self-locking turntable 6, a surface detection board 7, a cleaning mechanism 8, Plastic spray cover 9, plastic powder nozzle 10, electric heating head 11, plastic powder channel 12, plastic powder pump 13, feeding trough 14, oscillating sieve plate 15, screw agitator 16, lifting platform 17, powder suction pump 18, set Powder groove 19, powder guide pipe 20, spray plate 21, high-pressure water spray head 22 and drying fan 23, a travel guide 2 is horizontally framed in the spray case 1, and several groups of travel are arranged on the travel guide 2 The slider group 3, the top of the travel slider group 3 is symmetrically provided with a lifting mechanical arm 4, the top of the lifting mechanical arm 4 is horizontally arranged with a rotary motor 5, and the inner side of the rotary m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap