Novel moldable composite fireproof material

A kind of fireproof material, plastic technology, applied in the direction of synthetic resin layered products, building elements, layered products, etc., can solve the problems of difficult to change the shape of fireproof materials, application limitations, enlargement and other problems, to improve the bonding effect, excellent fireproofing effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

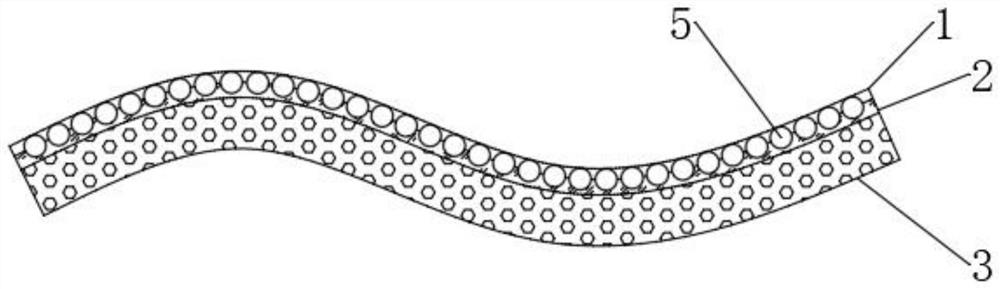

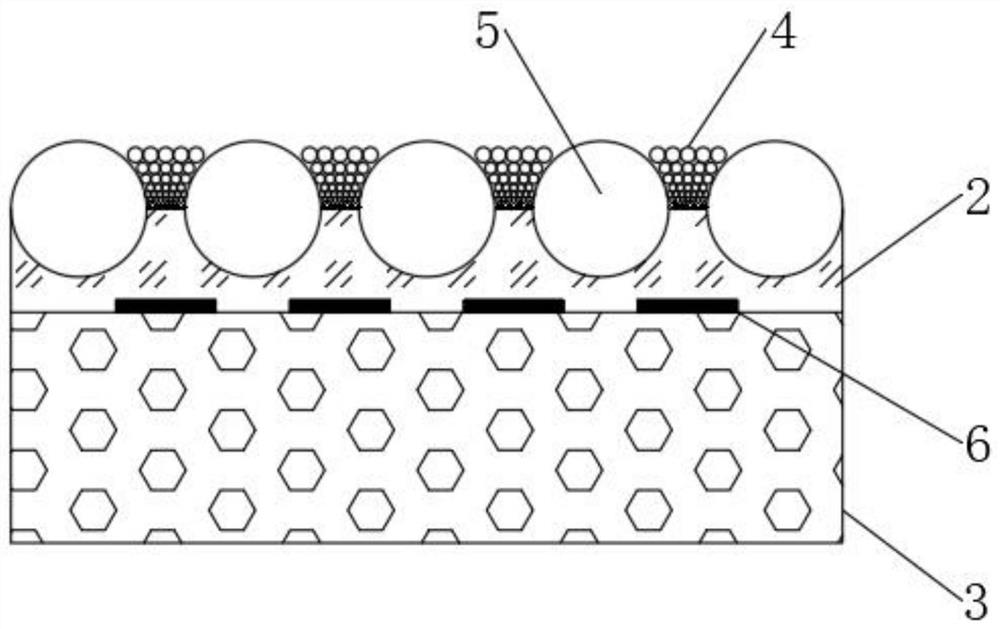

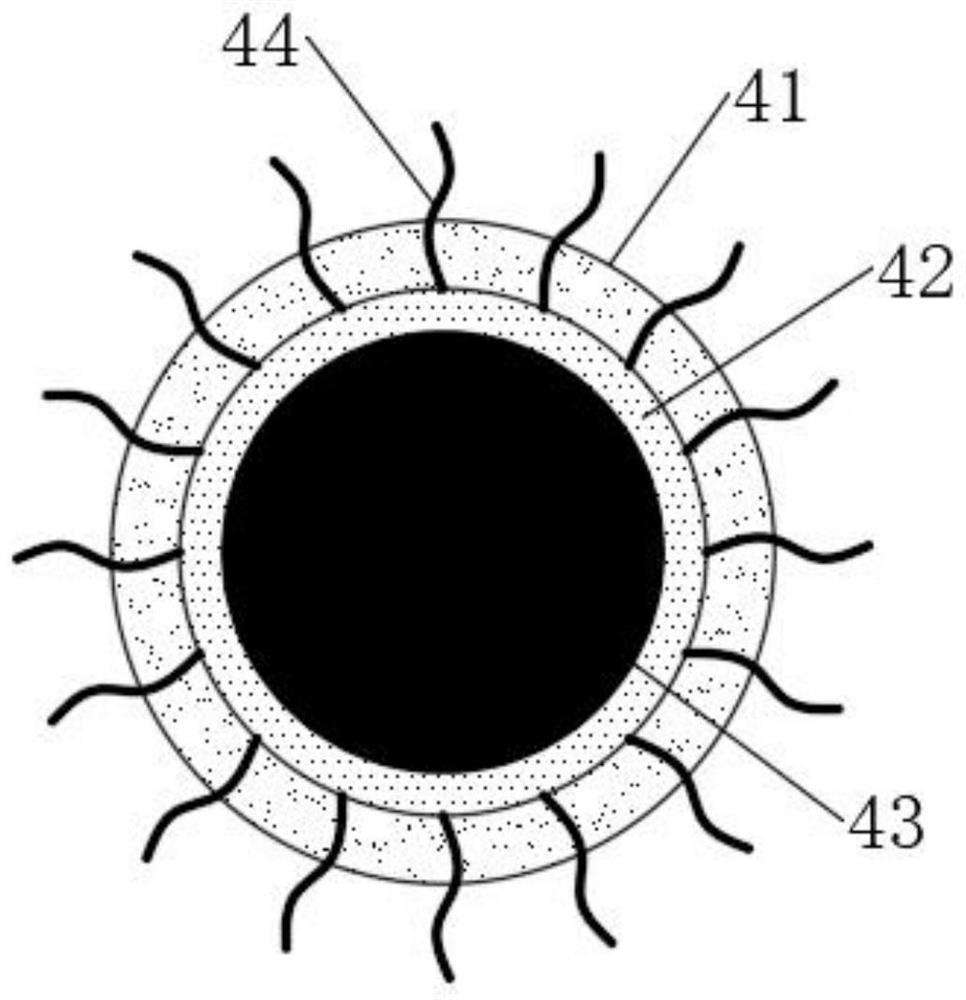

[0039] see Figure 1-2 , a new type of plastic composite fireproof material, which includes a fireproof layer 1, a heat insulation layer 2 and a plastic layer 3 from the outside to the inside. Skeleton balls 5 are evenly inlaid on the outer surface of heat insulation layer 2, and fireproof particles 4 and binder are mixed and filled in the gaps between fireproof skeleton balls 5. Heat insulation layer 2 is made of elastic heat insulation material, and heat insulation layer 2 One end near the shaping layer 3 is inlaid with a plurality of evenly distributed magnetic blocks 6. The shaping layer 3 includes a protective capsule, a polyurethane foam skeleton and a hot-melt substance. The polyurethane foam skeleton is filled in the protective capsule, and the polyurethane foam The skeleton is impregnated with a hot-melt substance. The polyurethane foam skeleton is a three-dimensional network structure, which is made by 3D printing. At high temperatures, the hot-melt substance is in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com