SLD icing detection method based on ice shape growth and icing detector

A technology of icing detectors and detection methods, which is applied in the field of icing detectors, can solve problems such as increased manufacturing costs, extremely high processing requirements, and icing, and achieves the effects of simple detection principles, simple structures, and simplified structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1. A kind of SLD icing detection method based on ice shape growth, carry out according to the following steps:

[0028] S1. The simulated icing time required for icing to a preset thickness on the largest ring wall 2 on the windward side of the spherical probe 1 is obtained through simulation;

[0029] S2. Collect the actual thickness of the ice within the simulated icing time on the largest ring wall 2 on the windward side of the spherical probe 1 in flight;

[0030] S3. Comparing calculation processing: comparing the preset thickness and the actual thickness described in the calculation, and outputting the calculation result.

[0031] According to the continuous simulation data, the optimal preset thickness is 0.5mm, and the simulated icing time at this time is about 30-60s; through the setting of this parameter, the detection time can be made more moderate and avoid excessive detection time. If the detection time is too long, it will affect the detection ef...

Embodiment 2

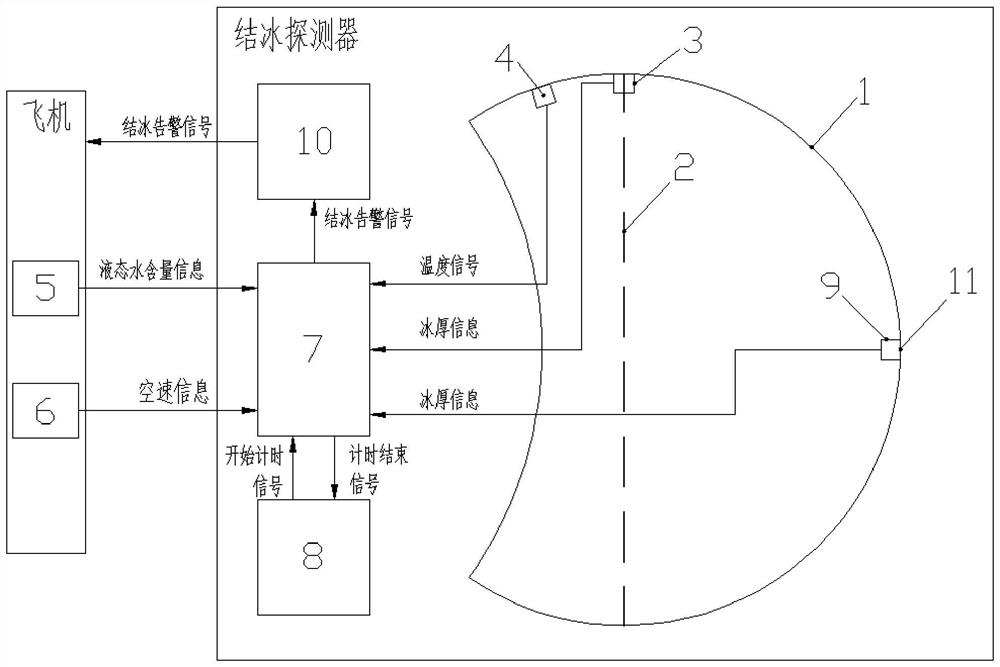

[0049] Example 2. A kind of icing detector used in SLD icing detection method, constitutes as figure 1 As shown, it includes spherical probe 1, temperature acquisition module 4, liquid water content identification module 5, wind speed detection module 6, ice thickness detection module I3, ice thickness detection module II9, timing module 8, data processing module 7, and alarm module . The ice thickness detection module I3 is used to collect the actual thickness of ice on the largest ring wall 2 on the windward side of the spherical probe 1 in flight; the ice thickness detection module II9 is used to collect the center 11 of the windward side of the spherical probe 1 Icing signal; temperature acquisition module 4, used to collect atmospheric static temperature in the flight environment; described liquid water content identification module 5, used to collect liquid water content in the flight environment; wind speed detection module 6, used to collect flight environment The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com