A kind of nanometer aluminum hydroxide accelerator and its preparation method and application

A nano-aluminum hydroxide and aluminum hydroxide technology, applied in the field of cement concrete admixtures, can solve the problems of complex process, unsuitable for large-scale promotion and application, difficult operation, etc., and achieve high reactivity, accelerated hydration and hardening, The effect of improving the early mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0020] The present invention will be described in detail below in conjunction with examples.

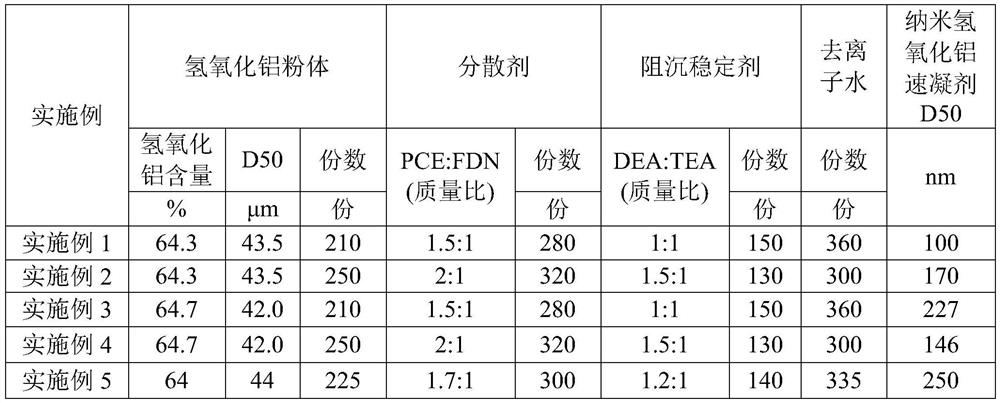

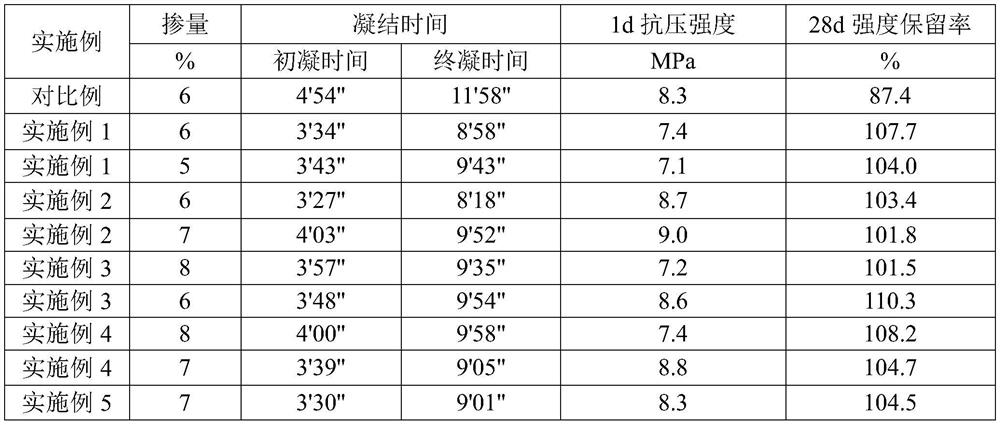

[0021] Table 1 shows the raw material ratio of the nano-aluminum hydroxide quick-setting agent of Examples 1 to 5 of the present invention and the particle size characteristics of the nano-aluminum hydroxide quick-setting agent of each embodiment.

[0022] Among them, the dispersant is a solution with a mass fraction of 10% made by mixing polycarboxylate superplasticizer (PCE) and naphthalene-based superplasticizer (FDN), and the anti-sedimentation stabilizer is diethanolamine (DEA) and triethanolamine (TEA). ) mixed mass fraction made of 10% solution, and the mass ratio of polycarboxylate water reducer (PCE) and naphthalene series water reducer (FDN) and diethanolamine (DEA) and triethanolamine (TEA) in each embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com