Preparation method and application of calcium carbonate nano-slurry in different crystal forms

A nano-slurry and calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of unsatisfactory use requirements, low early strength, etc., and achieve good application Foreground, improve early strength, good effect repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The specific embodiment of the present invention provides a kind of preparation method of different crystalline calcium carbonate nano slurry, and this preparation method comprises the steps:

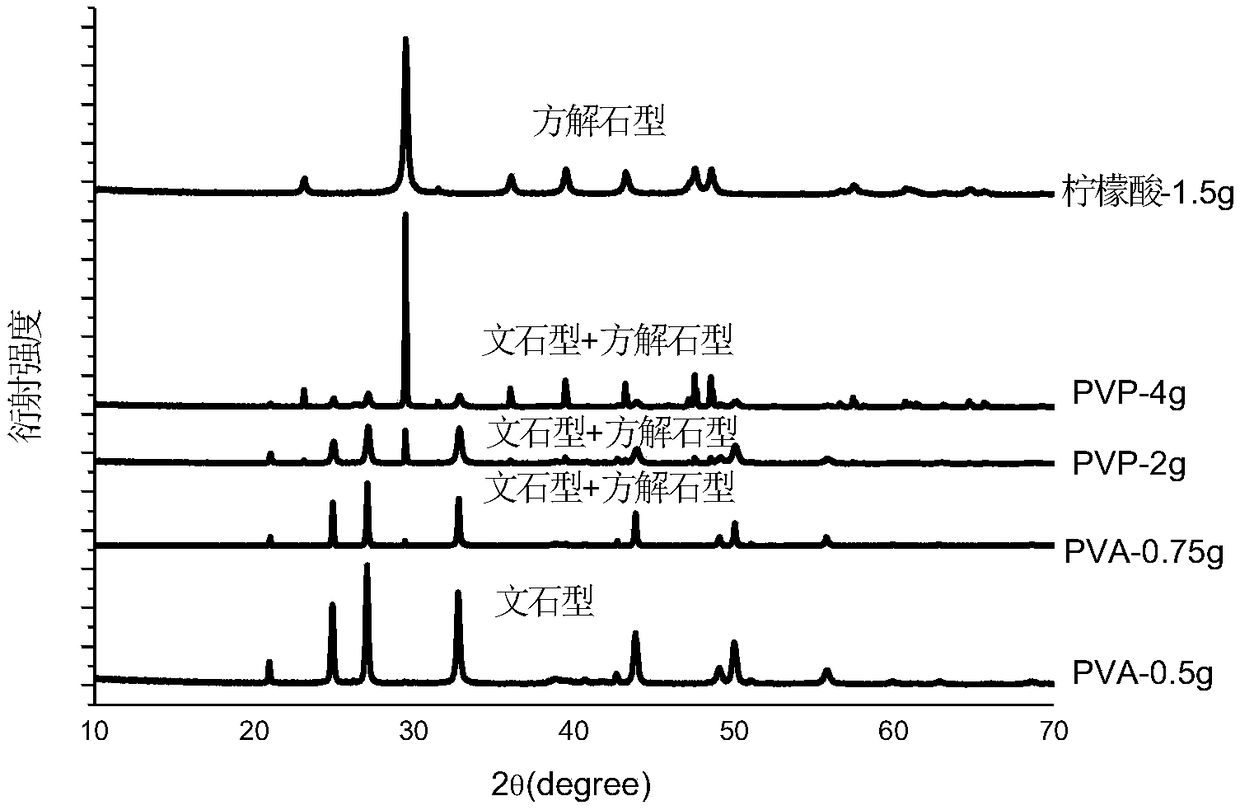

[0033] 1) Prepare the solution: prepare a certain concentration of calcium salt solution and carbonate solution with a solvent, and add a surfactant into the prepared calcium salt solution and carbonate solution. In the same group, the calcium salt solution and the carbonate solution use the same solvent and surfactant, and the generation of different crystal forms of calcium carbonate is controlled by changing the type of solvent and the type and dosage of surfactant in different groups.

[0034] In an embodiment of the present invention, the surfactant is one of polyvinylpyrrolidone (PVP), citric acid and polyvinyl alcohol (PVA). Preferably, the admixture of surfactant in calcium salt solution and carbonate solution is 1~9g / L (such as 1.5g / L, 2g / L, 2.5g / L, 3g / L, 3.5g / L, 4g / L,...

Embodiment 1

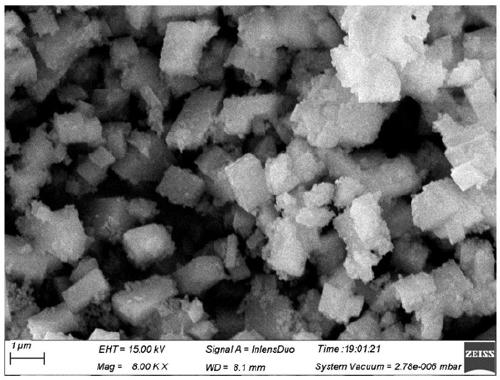

[0053] The preparation process of the nano calcium carbonate (pure aragonite type) slurry of the present embodiment is as follows:

[0054] Weigh 11.08g of anhydrous calcium chloride and 10.6g of anhydrous sodium carbonate, stir and dissolve them in the prepared hydroalcoholic solution (the volume ratio of water to ethanol is 2:3) in a water bath at 60°C, and constant volume In a 500mL volumetric flask, prepare 0.2mol / L calcium chloride solution and 0.2mol / L sodium carbonate solution; weigh two parts of 0.5g polyvinyl alcohol (PVA) as surfactant and dissolve in 500ml calcium salt solution respectively And in the carbonate solution of 500ml; The two kinds of solutions that have configured are poured into the colloid mill evenly and slowly at the same rate, make it mix and react rapidly and flow out from the outlet to obtain a mixed slurry. The resulting slurry was then aged for 24 h. Use deionized water to wash and centrifuge several times until the pH value of its supernatant...

Embodiment 2

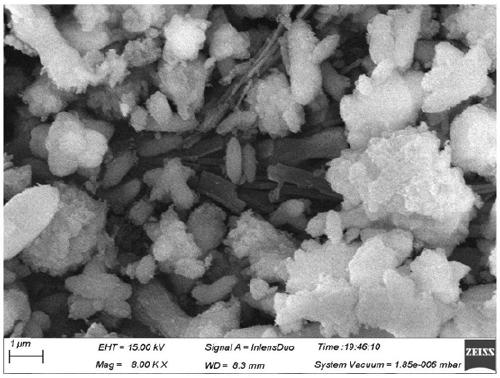

[0060] The preparation process of the nano calcium carbonate (aragonite, calcite mixed crystal form) slurry of the present embodiment is as follows:

[0061] Weigh 11.08g of anhydrous calcium chloride and 10.6g of anhydrous sodium carbonate, stir and dissolve them in the prepared hydroalcoholic solution (the volume ratio of water to ethanol is 2:3) in a water bath at 60°C, and constant volume In a 500mL volumetric flask, prepare 0.2mol / L calcium chloride solution and 0.2mol / L sodium carbonate solution; weigh two parts of 0.75g polyvinyl alcohol (PVA) as surfactant and dissolve in 500ml calcium salt solution respectively And in the carbonate solution of 500ml; The two kinds of solutions that have configured are poured into the colloid mill evenly and slowly at the same rate, make it mix and react rapidly and flow out from the outlet to obtain a mixed slurry. The resulting slurry was then aged for 24 h. , using deionized water to wash and centrifuge several times until the pH v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com