Composite acetone enhanced alkali-free liquid setting accelerator

A technology of quick-setting agent and stabilizing enhancer, which is applied in the field of building materials for support engineering, and can solve the problems of concrete strength reduction, crystallization and delamination, skin damage, etc., to solve the problem of strong corrosion, improve compressive strength, reduce The effect of rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

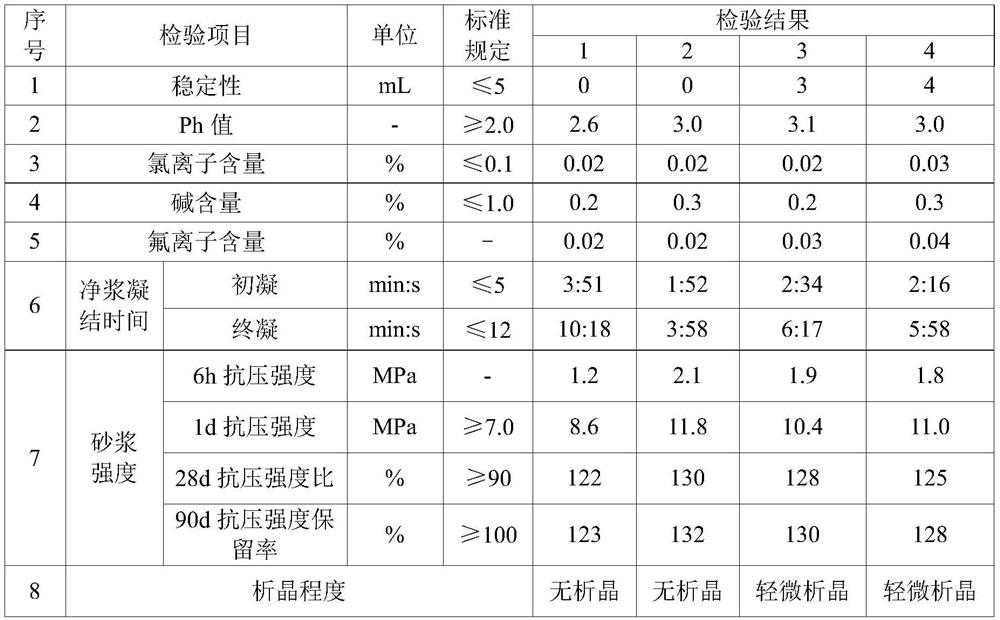

Examples

Embodiment 1

[0025] The components in this example are: Fluosilicic acid: 17 parts by weight; Aluminum hydroxide: 4 parts by weight; Acrylic acid: 0.2 parts by weight; Aluminum sulfate: 36 parts by weight; Zinc oxide: 0.01 parts by weight; Magnesium hydroxide: 7 parts by weight Parts by weight; magnesium silicate: 4 parts by weight; potassium hydroxide: 0.4 parts by weight; suspending agent: 0.2 parts by weight; acetone: 0.1 parts by weight; stability enhancer: 0.4 parts by weight; tap water: 30.69 parts by weight;

[0026] According to the above composition ratio requirements, each raw material composition was weighed, and prepared according to the following method:

[0027] Step 1: Coordinate Fluorosilicic Acid

[0028] In order to control the production cost, this embodiment selects silica fume coordination; the silica fume used is required to be close to white, the silica content is greater than 85%, and the specific surface area is controlled at 20000m 2 / Kg; Add an appropriate amoun...

Embodiment 2

[0040] In this embodiment, the components are: fluosilicic acid: 18 parts by weight; aluminum hydroxide: 5 parts by weight; acrylic acid: 0.2 parts by weight; aluminum sulfate: 38 parts by weight; zinc oxide: 0.02 parts by weight; Parts by weight; magnesium silicate: 3 parts by weight; potassium hydroxide: 0.1 parts by weight; suspending agent: 0.3 parts by weight; acetone: 0.2 parts by weight; stability enhancer: 0.5 parts by weight; tap water: 26.68 parts by weight;

[0041] According to the above composition ratio requirements, each raw material composition was weighed, and prepared according to the following method:

[0042] Step 1: Coordinate Fluorosilicic Acid

[0043] In order to control the production cost, this embodiment selects silica fume coordination; the silica fume used is required to be close to white, the silica content is greater than 85%, and the specific surface area is controlled at 20000m 2 / Kg; Add an appropriate amount of silica fume into the weighed f...

Embodiment 3

[0055] The components in this embodiment are: fluosilicic acid: 19 parts by weight; aluminum hydroxide: 6 parts by weight; acrylic acid: 0.3 parts by weight; aluminum sulfate: 39 parts by weight; zinc oxide: 0.03 parts by weight; Parts by weight; magnesium silicate: 2 parts by weight; potassium hydroxide: 0.2 parts by weight; suspending agent: 0.4 parts by weight; acetone: 0.3 parts by weight; self-made stabilization enhancer: 0.4 parts by weight;

[0056] According to the above composition ratio requirements, each raw material composition was weighed, and prepared according to the following method:

[0057] Step 1: Coordinate Fluorosilicic Acid

[0058] In order to control the production cost, this embodiment selects silica fume coordination; the silica fume used is required to be close to white, the silica content is greater than 85%, and the specific surface area is controlled at 20000m 2 / Kg; Add an appropriate amount of silica fume into the weighed fluosilicic acid and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com