Smelting slag double-layer centrifugal granulation device with air quenching function

A centrifugal granulation and functional technology, which is applied in the field of smelting slag granulation, can solve the problems of lower vitreous conversion rate, lower vitreous conversion rate, and overheating of the granulation chamber wall, so as to improve the granulation effect and quality, increase the The effect of crushing and granulation, and the effect of increasing the amount of slag treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

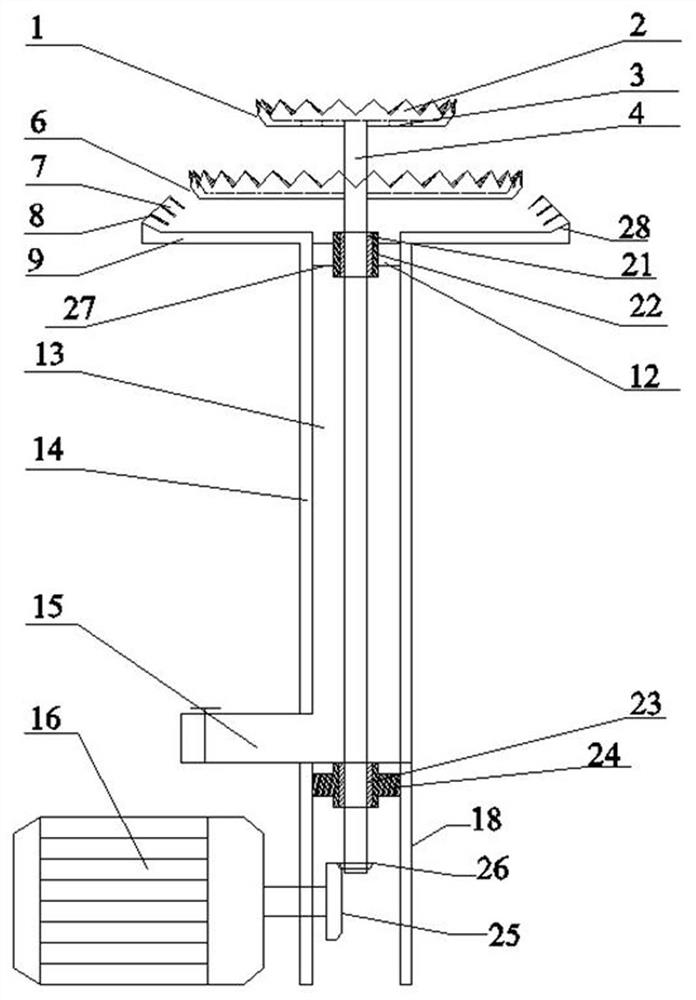

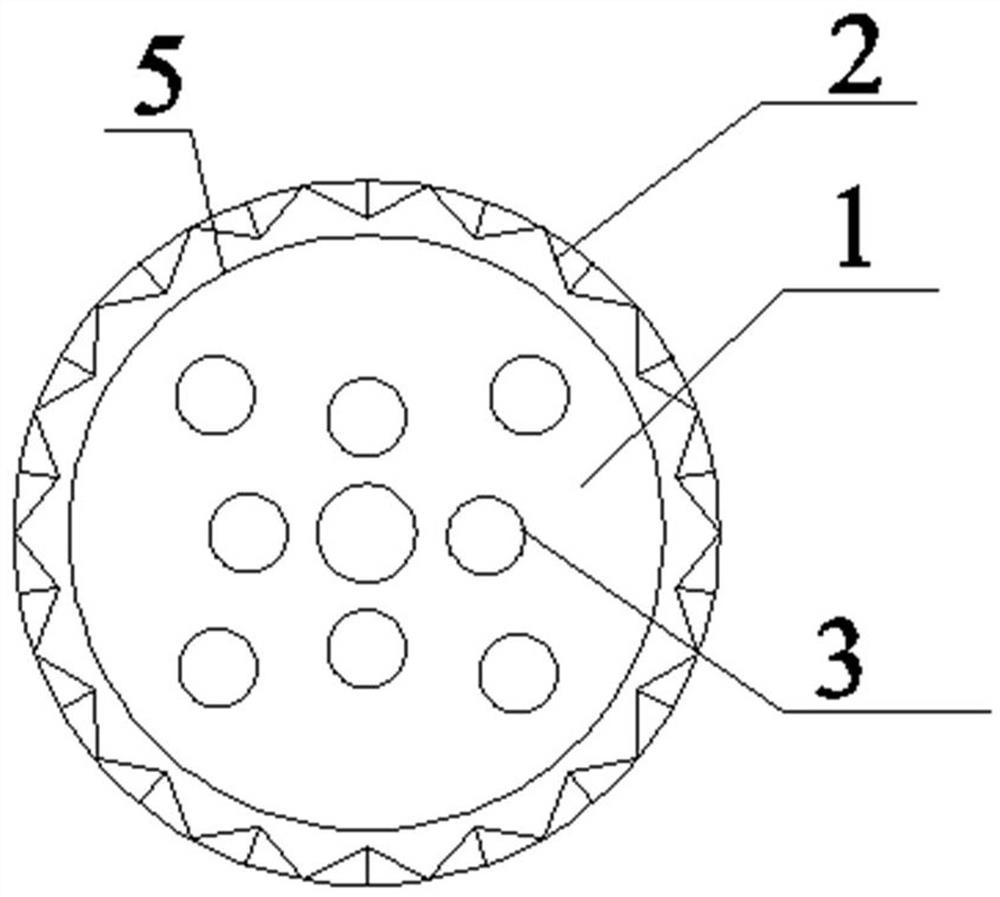

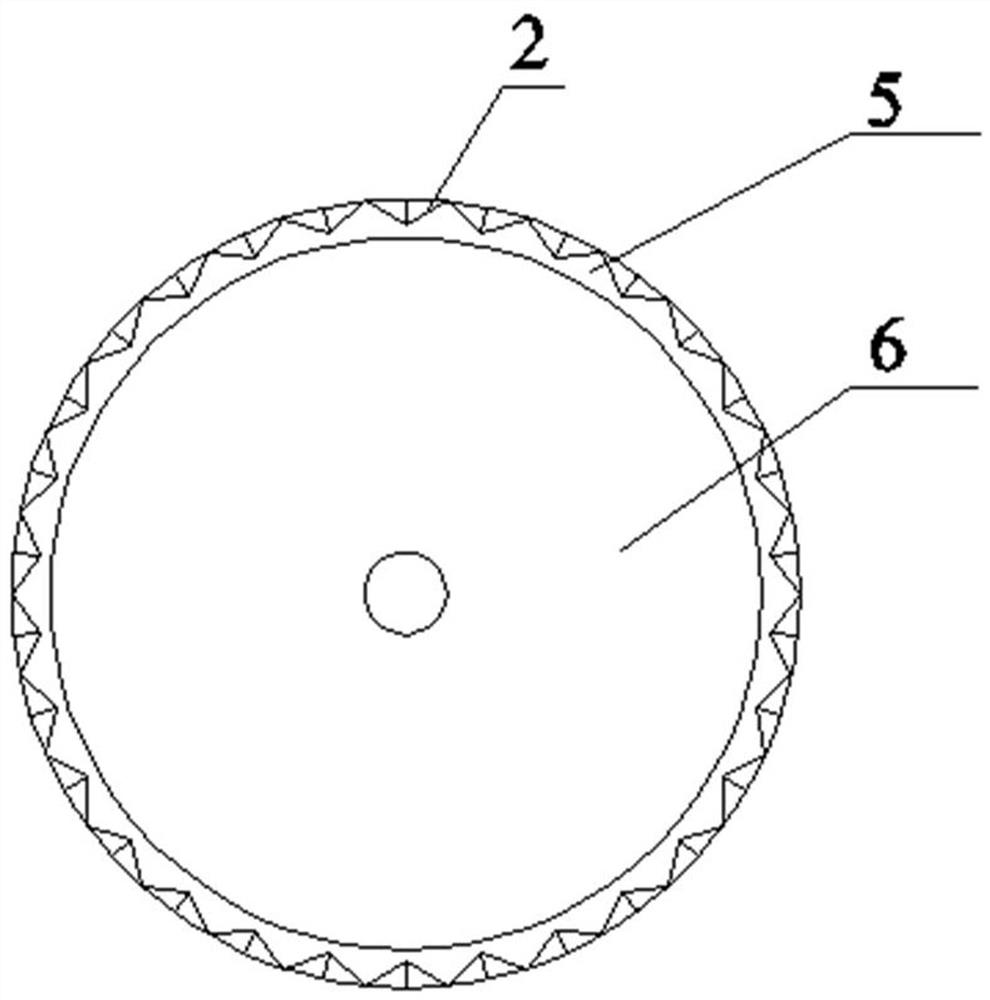

[0029] Such as Figure 1-5The shown is a double-layer centrifugal granulation device for smelting slag with air quenching function, including the upper rotor cup 1, the lower rotor cup 6, the air guiding chassis 9, the air duct sleeve 14, the rotating shaft 4, the motor 16 and the fixed bracket 18. The upper rotor cup 1, the lower rotor cup 6, and the wind guide chassis 9 are all circular disk-shaped structures, and the edges of the upper rotor cup 1 and the lower rotor cup 6 are all provided with sloped bosses 5, and the The slope bosses 5 of the upper rotor cup 1 and the lower rotor cup 6 are evenly distributed with dense serrations 2, which can cut the slag liquid film rotating at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com