Preparation method of yoghourt capable of preventing whey from being separated out

A technology of yogurt and whey, applied in dairy products, milk preparations, other dairy products, etc., can solve problems such as yogurt syneresis, achieve the effects of preventing whey precipitation, prolonging storage life, and reducing syneresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing yogurt for preventing whey precipitation, comprising the following steps:

[0030] S1, taking milk, and adjusting the pH value of the milk to 5.0-6.7 with an acidity regulator such as citric acid, dilute hydrochloric acid or lactic acid, to obtain emulsion A;

[0031] S2, adding TG enzyme to the emulsion A prepared in step S1, and incubating to obtain emulsion B, wherein the incubation temperature is 30-60°C, and the incubation time is 1.3-1.8h;

[0032] S3, adjust the pH value of the NaOH solution used in the emulsion B prepared in step S2 to 6.5-6.7, carry out sterilization and sterilizing enzymes, and store after adding fermented substances; wherein, the temperature for sterilizing and sterilizing enzymes is 80-100° C., and the time is 3 to 8 minutes; the fermented substance is bacteria or glucono-δ-lactone.

Embodiment 2

[0034] A method for preparing yogurt for preventing whey precipitation, comprising the following steps:

[0035] S1, take 4000g of fresh milk and place it in a refrigerated centrifuge, centrifuge at 4°C for 25 minutes, and collect the lower layer of milk;

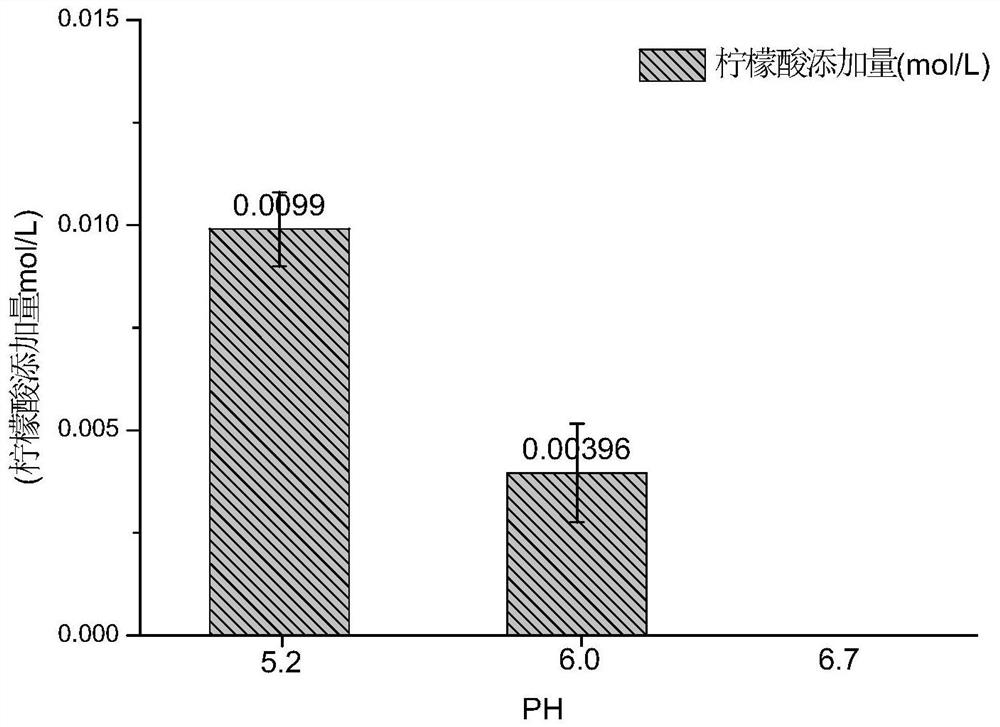

[0036] S2, using 1 mol / L citric acid to adjust the pH value of the milk in step S1, so that the pH of the milk is 6.7, to obtain emulsion A, and record the required amount of citric acid;

[0037] S3, adding 3 U / g of TG enzyme to the emulsion A prepared in step S2, then stirring for 3 minutes under the action of a magnetic stirrer to completely disperse it, and incubating at 45° C. for 1.5 hours to obtain emulsion B;

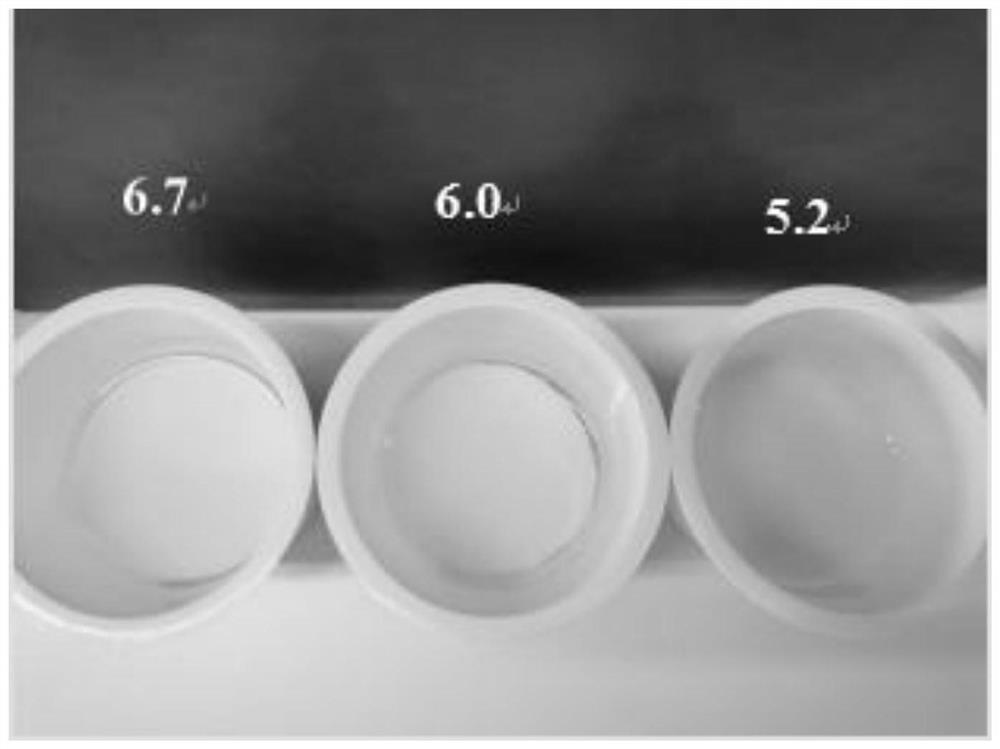

[0038] S4, using 1mol / L dilute NaOH solution, adjust the pH value of the emulsion B prepared in step S3 to 6.5, sterilize the enzyme at 95°C for 5min, add 100DCU / T strains, and place at 43°C After 4 hours in a constant temperature box, the yoghurt samples were obtained, and finally the samples were stored at...

Embodiment 3

[0040] A method for preparing yogurt for preventing whey precipitation, comprising the following steps:

[0041] S1, take 4000g of fresh milk and place it in a refrigerated centrifuge, centrifuge at 4°C for 25 minutes, and collect the lower layer of milk;

[0042] S2, using 1 mol / L citric acid to adjust the pH value of the milk in step S1, so that the pH of the milk is 6.0, to obtain emulsion A, and record the required amount of citric acid;

[0043] S3, adding 3 U / g of TG enzyme to the emulsion A prepared in step S2, then stirring for 3 minutes under the action of a magnetic stirrer to completely disperse it, and incubating at 45° C. for 1.5 hours to obtain emulsion B;

[0044] S4, using 1mol / L dilute NaOH solution, adjust the pH value of the emulsion B prepared in step S3 to 6.5, sterilize the enzyme at 95°C for 5min, add 1% to 2% gluconic acid-δ- lactone, and placed in a thermostat at 43°C for 4 hours, then cooled to obtain a yoghurt sample, and finally the sample was stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com