Lightweight high-strength concrete and preparation method thereof

A high-strength concrete, light-weight technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems that the compressive strength of concrete is difficult to meet the construction requirements, increase the content of ceramic sand, and the strength of ceramic sand is low, and achieve light weight. , high strength, reducing the effect of bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0040] The water reducer is made by mixing and stirring the following raw materials in parts by weight:

[0041] Water-reducing mother liquor 20kg, slump-preserving mother liquor 8kg, viscosity reducer 5kg, defoamer 0.3kg, retarder 1kg and water 50kg.

preparation example 2

[0043] Water-reducing mother liquor 25kg, slump-preserving mother liquor 13kg, viscosity reducer 7kg, defoamer 0.8kg, retarder 2kg and water 53kg.

[0044] Preparation example 2

[0045] Water-reducing mother liquor 30kg, slump-preserving mother liquor 18kg, viscosity reducer 10kg, defoamer 1.2kg, retarder 3kg and water 55kg.

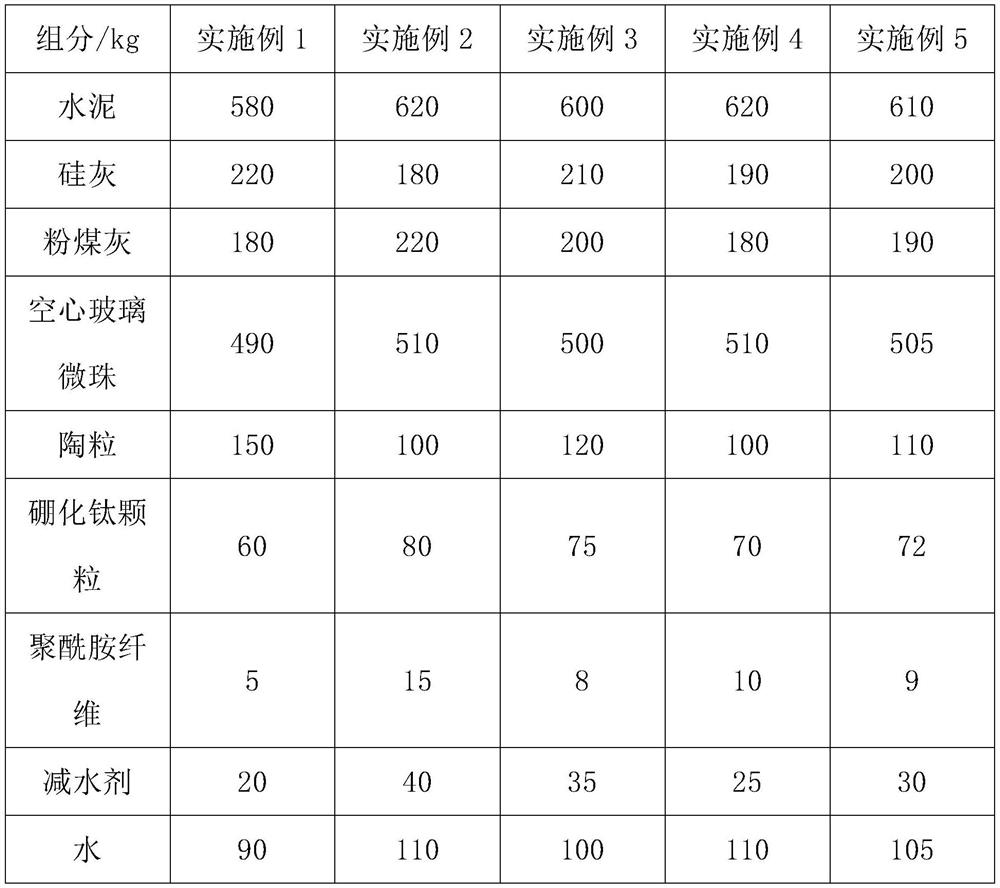

Embodiment 1

[0048] A lightweight high-strength concrete made from the following raw materials in parts by weight:

[0049] 580kg of cement, 220kg of silica fume, 180kg of fly ash, 490kg of hollow glass microspheres, 150kg of ceramsite, 60kg of titanium boride particles, 5kg of polyamide fiber, 20kg of water reducing agent, and 90kg of water.

[0050] The silicon dioxide content in silica fume is 92%; the density of hollow glass microspheres is 350g / cm 3 The cylinder compressive strength of ceramsite is 5MPa; the particle size of titanium boride is 8 microns; the length of polyamide fiber is 10mm;

[0051] Lightweight high-strength concrete is prepared through the following steps:

[0052] S1: Mix cement, silica fume, fly ash, hollow glass microspheres and water in a mixer for 60 seconds to obtain ready-mixed concrete;

[0053] S2: Add ceramsite, titanium boride particles, fibers and water reducer to the ready-mixed concrete, and stir for 4-5 minutes to obtain evenly mixed ready-mixed co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com