Sulfonated naphthol bola-type surfactant for heavy oil reservoir flooding and its synthesis method and application

A technology of surfactant and sulfonated naphthol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high oil displacement cost of surfactants, difficulty in heavy oil recovery, etc. The effect of water-oil mobility ratio, enhanced sweep capacity, and enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

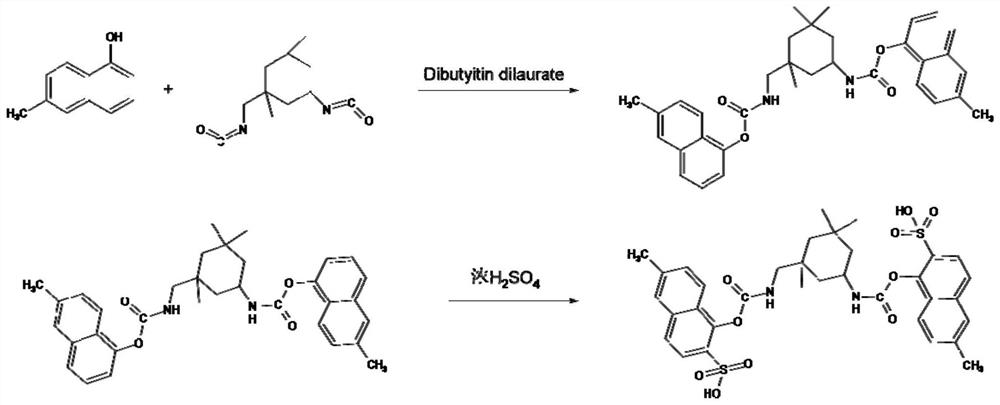

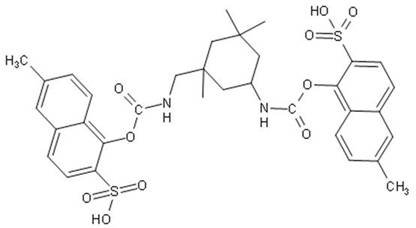

[0028] Concretely, a kind of preparation method of sulfonated naphthol Bola-type surfactant for oil displacement of heavy oil reservoir, comprising the following steps:

[0029] (1) Mix 6-methyl-1-naphthol, isophorone diisocyanate (IPDI) and a catalyst, the moles of the 6-methyl-1-naphthol and isophorone diisocyanate (IPDI) The ratio is 2:(1~1.10); the catalyst is dibutyltin dilaurate, and the addition amount is 0.5wt%. Be warming up to 60~100 ℃, react 8~12 hours, obtain intermediate;

[0030] (2) Add concentrated sulfuric acid and a solvent to the intermediate, and the solvent is dichloromethane; the mass fraction of the concentrated sulfuric acid is 98%; the molar ratio of the intermediate to the 98% concentrated sulfuric acid is 1:2.05. The reaction was carried out at normal temperature, and the reaction time was 30 minutes to obtain a crude product;

[0031] (3) The crude product was vacuum-dried and dissolved in ethyl acetate. The ester layer was washed with water and s...

Embodiment 1

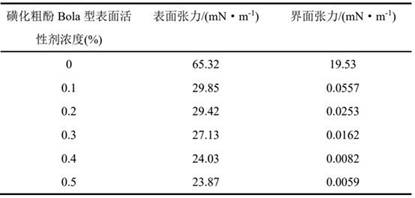

[0035] A mixture of 6-methyl-1-naphthol and isophorone diisocyanate (IPDI) in a molar ratio of 2:1 and dibutyltin dilaurate 0.5 wt % was added to the flask, heated to 100° C., and reacted for 10 hours. to obtain intermediates. The molar ratio of the intermediate and the mass fraction of 98% concentrated sulfuric acid is 1:2.05. The reaction was carried out at normal temperature and the reaction time was 30 minutes to obtain a crude product. The crude product was dried in vacuo and dissolved in ethyl acetate. The ester layer was washed with water and saturated brine respectively, and dried over anhydrous MgSO4. The ethyl acetate was evaporated under reduced pressure and dried in vacuo to obtain the product. The product is sulfonated 6-methyl-1-naphthol Bola-type surfactant. First, the core is saturated with simulated formation water, the permeability of the core is measured, and then the crude oil is saturated. After standing for 24 hours at the simulated formation temperat...

Embodiment 2

[0037]A mixture of 6-methyl-1-naphthol and isophorone diisocyanate (IPDI) in a molar ratio of 2:1 and dibutyltin dilaurate 0.5wt% was added to the flask, the temperature was raised to 80°C, and the reaction was carried out for 10 hours. to obtain intermediates. The molar ratio of the intermediate and the mass fraction of 98% concentrated sulfuric acid is 1:2.05. The reaction was carried out at normal temperature and the reaction time was 30 minutes to obtain a crude product. The crude product was dried in vacuo and dissolved in ethyl acetate. The ester layer was washed with water and saturated brine respectively, and dried over anhydrous MgSO4. The ethyl acetate was evaporated under reduced pressure and dried in vacuo to obtain the product. The product is sulfonated 6-methyl-1-naphthol Bola-type surfactant. First, the core is saturated with simulated formation water, the permeability of the core is measured, and then the crude oil is saturated. After standing for 24 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com