Sulfonated crude phenol Bola type surfactant as well as synthesis method and application thereof

A technology of surfactant and sulfonated crude phenol, which is applied in chemical instruments and methods, organic chemistry, sulfonic acid preparation, etc., can solve the problems of small affected area, low utilization rate of crude phenol, poisonous oil, etc., and achieve recovery The effect of increasing the rate, wide source, and reducing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

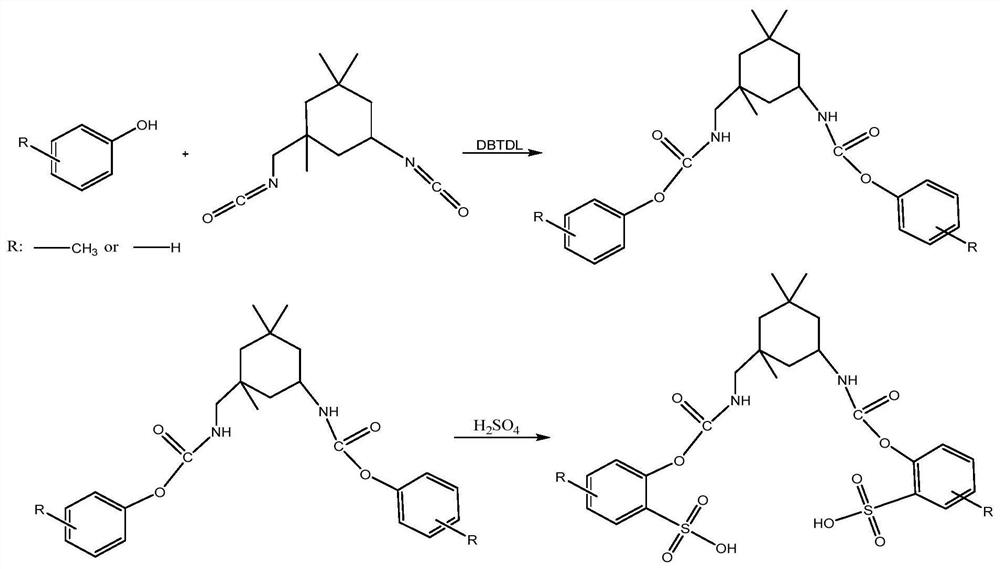

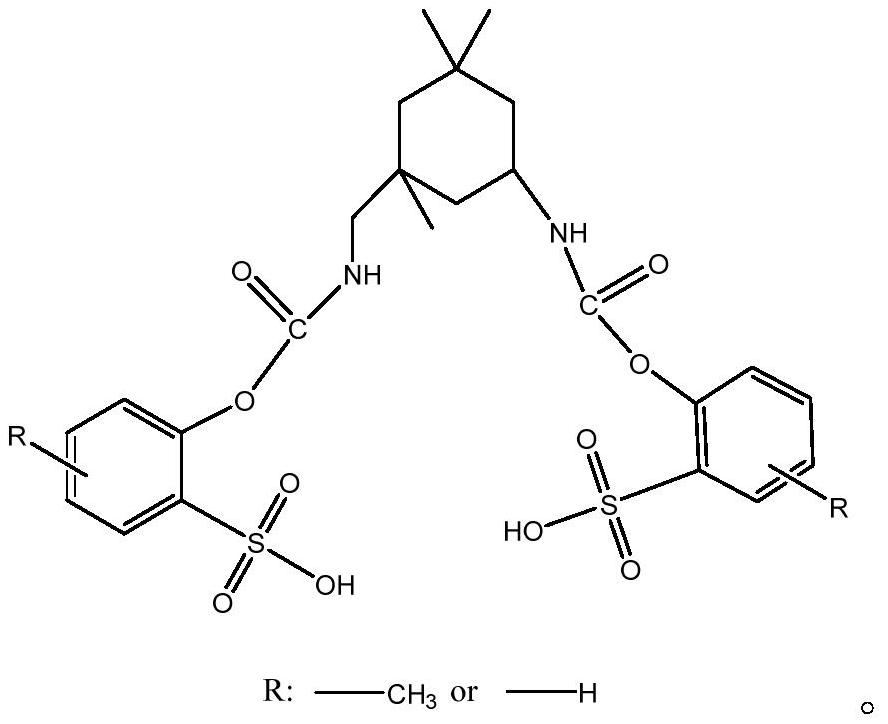

[0029] Concrete, the synthetic method of sulfonated crude phenol Bola type surfactant and its application as oil displacement agent, comprise the following steps:

[0030] (1) Put the crude phenol after vacuum drying into the flask, add dibutyltin dilaurate to mix, and slowly add isophorone diisocyanate dropwise. Wherein the crude phenol must be vacuum-dried. The molar ratio of isophorone diisocyanate to crude phenol is 1:(2~2.1). The addition amount of dibutyltin dilaurate is 0.5wt%. Under nitrogen protection, heat up to 60-100°C, react for 8-10 hours, depressurize and evacuate to obtain the intermediate.

[0031] Described crude phenol refers to phenol: 2-methylphenol: the mol ratio of 3-methylphenol is 1.0:0.2:0.7, and described diisocyanate is isophorone diisocyanate (IPDI), and described isophorone The molar ratio of diisocyanate (IPDI) to crude phenol is 1:(2-2.1); the catalyst is dibutyltin dilaurate (DBTDL), and the addition amount is 0.5wt%.

[0032] (2) the inter...

Embodiment 1

[0039] The molar ratio of isophorone diisocyanate and crude phenol (phenol: 2-methylphenol: 3-methylphenol molar ratio is 1.0:0.2:0.7) is 1:2.05, dibutyltin dilaurate 0.5wt% The mixture was added into a flask, under nitrogen protection, reacted at 60° C. for 8 hours, and vacuumed under reduced pressure to obtain an intermediate. Take the intermediate and concentrated H 2 SO 4 Molar ratio is 1:2.05, add dichloromethane solvent, concentrated H 2 SO 4 The mass fraction was 98%, and the reaction time was 30 minutes at 70° C. to obtain a crude product. The crude product was vacuum-dried, then dissolved in ethyl acetate, and the ethyl acetate layer was washed with water and saturated brine respectively, and anhydrous MgSO 4 dry. Ethyl acetate was distilled off under reduced pressure to obtain the product. The product is sulfonated crude phenol Bola surfactant. First set the permeability to 1.2~3.0μm 2 The man-made cores were evacuated and saturated with groundwater, and then...

Embodiment 2

[0041] The molar ratio of isophorone diisocyanate and crude phenol (phenol: 2-methylphenol: 3-methylphenol molar ratio is 1.0:0.2:0.7) is 1:2.1, dibutyltin dilaurate 0.5wt% The mixture was added into a flask, under nitrogen protection, reacted at 100° C. for 8 hours, and vacuumed under reduced pressure to obtain an intermediate. Take the intermediate and concentrated H 2 SO 4 Molar ratio is 1:2.05, add dichloromethane solvent, concentrated H 2 SO 4 The mass fraction was 98%, and the reaction time was 30 minutes at 70° C. to obtain a crude product. The crude product was vacuum-dried, then dissolved in ethyl acetate, and the ethyl acetate layer was washed with water and saturated brine respectively, and anhydrous MgSO 4 dry. Ethyl acetate was distilled off under reduced pressure to obtain the product. The product is sulfonated crude phenol Bola surfactant. First set the permeability to 1.2~3.0μm 2 The man-made cores were evacuated and saturated with groundwater, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com