Purification method for chlorin e6

A chlorin and purification method technology, applied in the field of medicine, can solve the problems of unstable process, high equipment requirements, complex chlorophyll a extraction and purification process, etc., and achieve high purification efficiency, simple and stable process operation, and enhanced solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

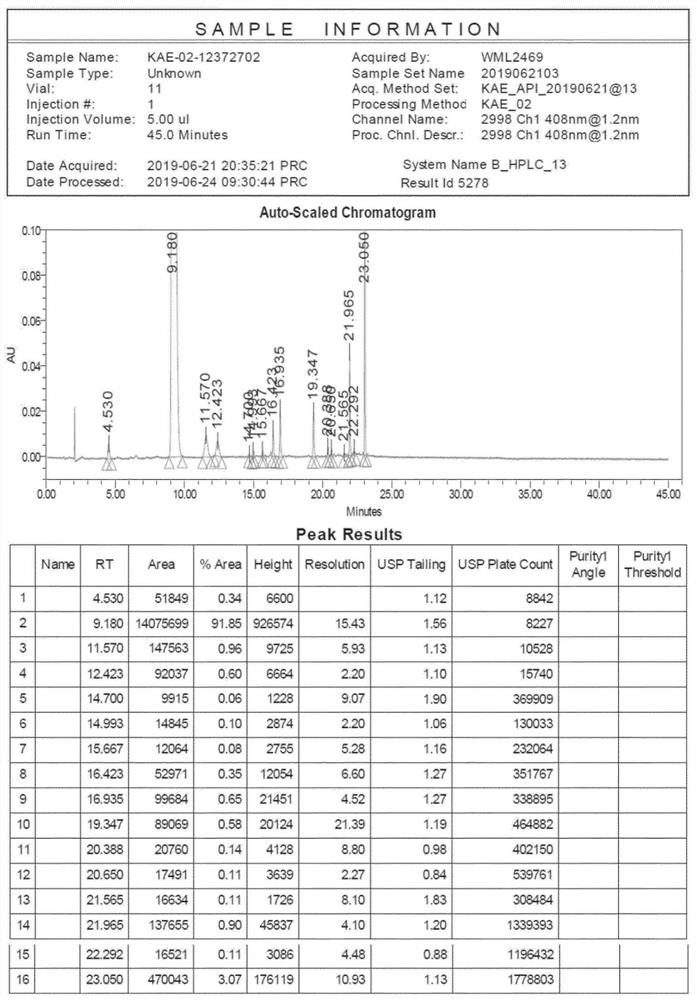

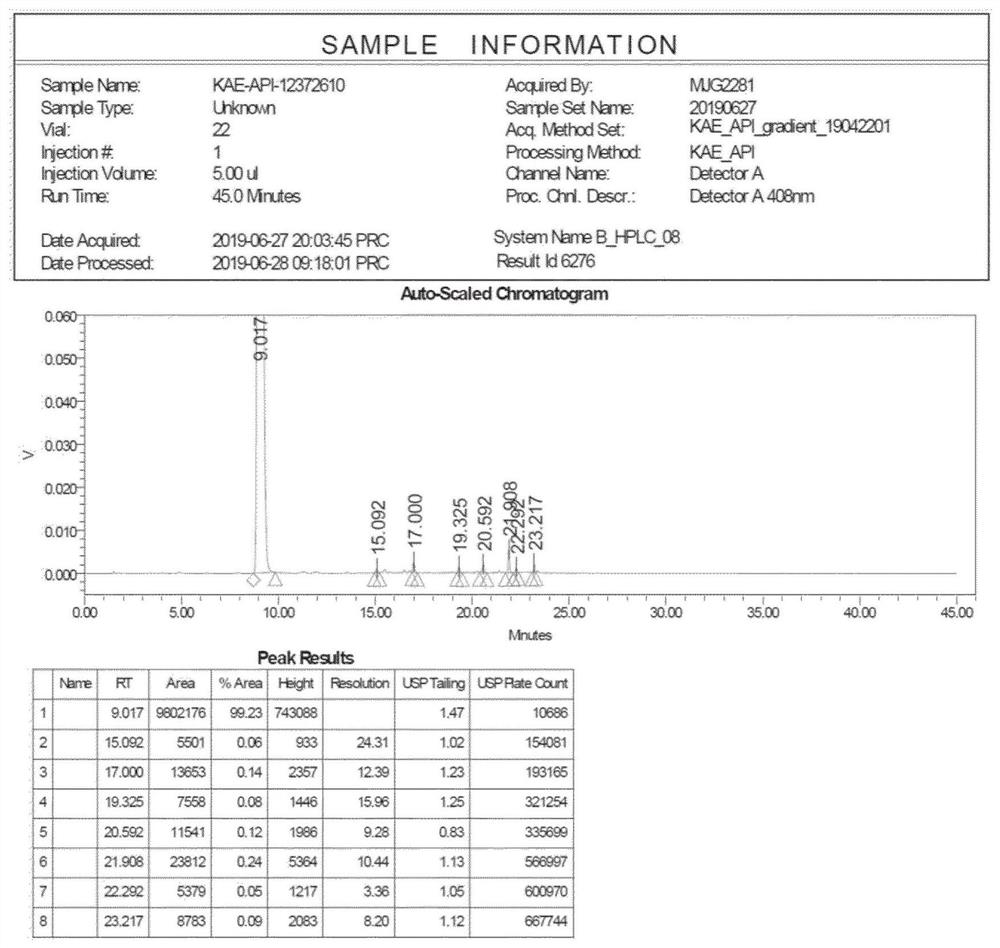

Image

Examples

Embodiment 1

[0030] Embodiment 1: Salt formation of chlorin e6 and meglumine

[0031] Under the protection of argon, add 200g of crude chlorin e6 into 1L of tetrahydrofuran, heat to 50-60°C, and stir to dissolve. Add 196.31 g of meglumine, stir for 1 h, then lower the temperature to 0-10° C. and crystallize for 2 h. Filter, rinse the filter cake with 200mLTHF, and dry to obtain 357.07g of chlorin e6 meglumine salt, with a yield of 90.10%.

Embodiment 2

[0032] Example 2: Dissociation of chlorin e6 meglumine salt

[0033] Under argon protection, 350g of chlorin e6 meglumine salt in Example 1 was dissolved in a mixed solution of 1L of tetrahydrofuran and water, cooled to 0-10°C, and 10% hydrochloric acid solution was added dropwise to adjust the pH= 3-4, more solids were precipitated, continued to stir and crystallize for 2 hours, filtered, washed the filter cake with 350ml of water, and dried in vacuo to obtain 168.15g of chlorin e6 with a yield of 95.20%.

Embodiment 3

[0034] Embodiment 3: Salt formation of chlorin e6 and ethanolamine

[0035] Under the protection of argon, add 100g of crude chlorin e6 into 1.20L of acetone, heat to 50-60°C, and stir to dissolve. Add 30.71g of ethanolamine, stir for 2h, then cool down to 0-10°C for crystallization for 2h. Filter, rinse the filter cake with 50 mL of acetone, and dry to obtain 117.26 g of chlorin e6 ethanolamine salt, with a yield of 89.71%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com