Hollow anti-resonance optical fiber

An anti-resonance, optical fiber technology, applied in cladding optical fiber, microstructure optical fiber, multi-layer core/clad optical fiber, etc., can solve the problems of narrowing transmission bandwidth, oscillating change of loss spectrum, and reducing transmission bandwidth, etc., to achieve Uniform cavity area distribution, stable loss spectrum characteristics, and effects of avoiding resonance phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

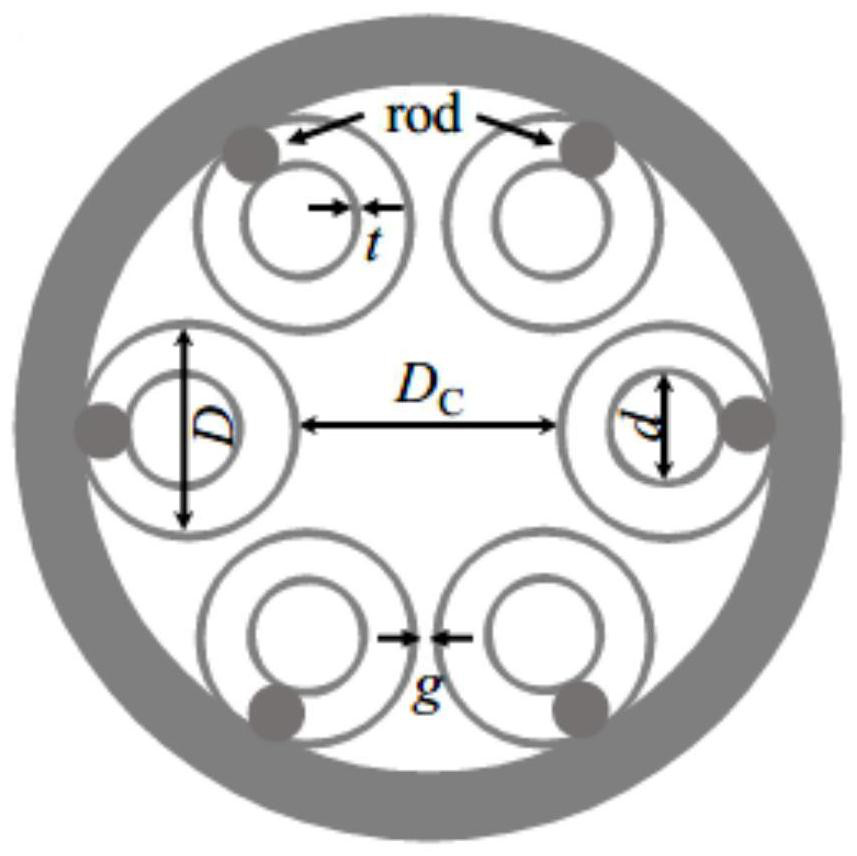

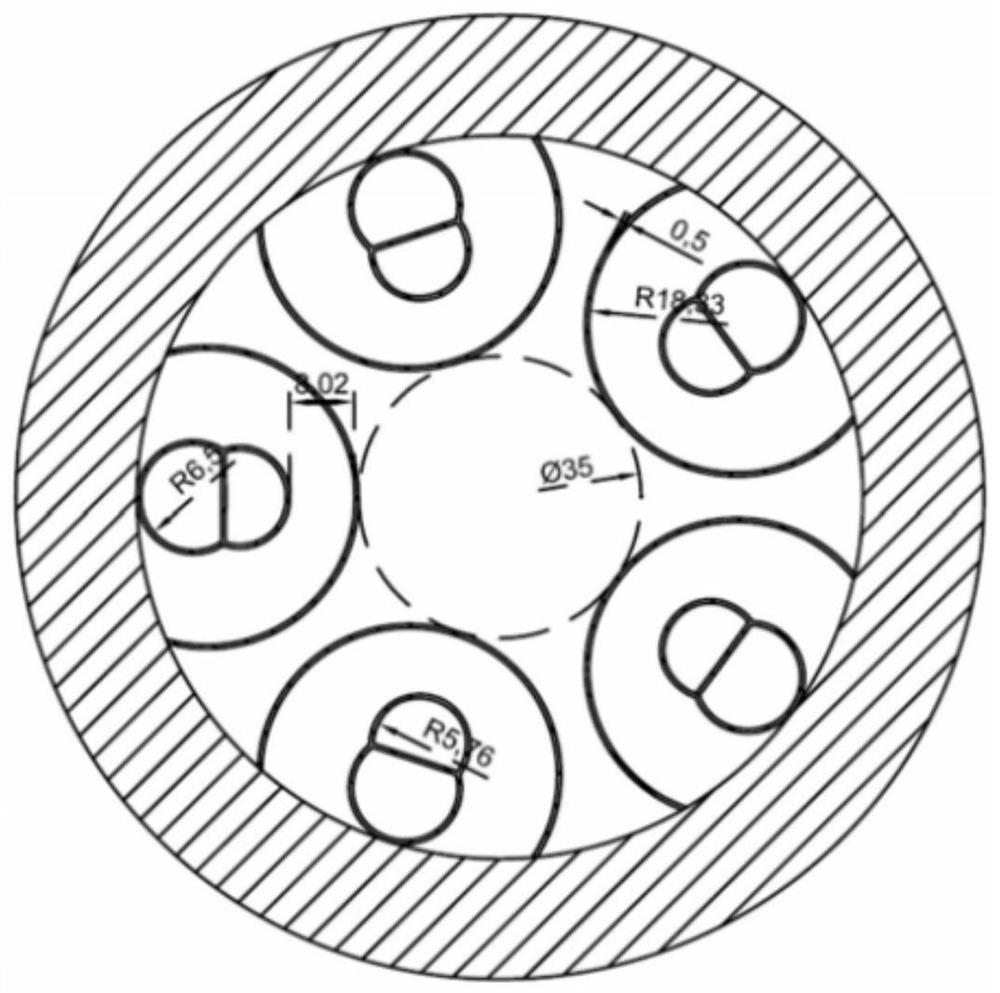

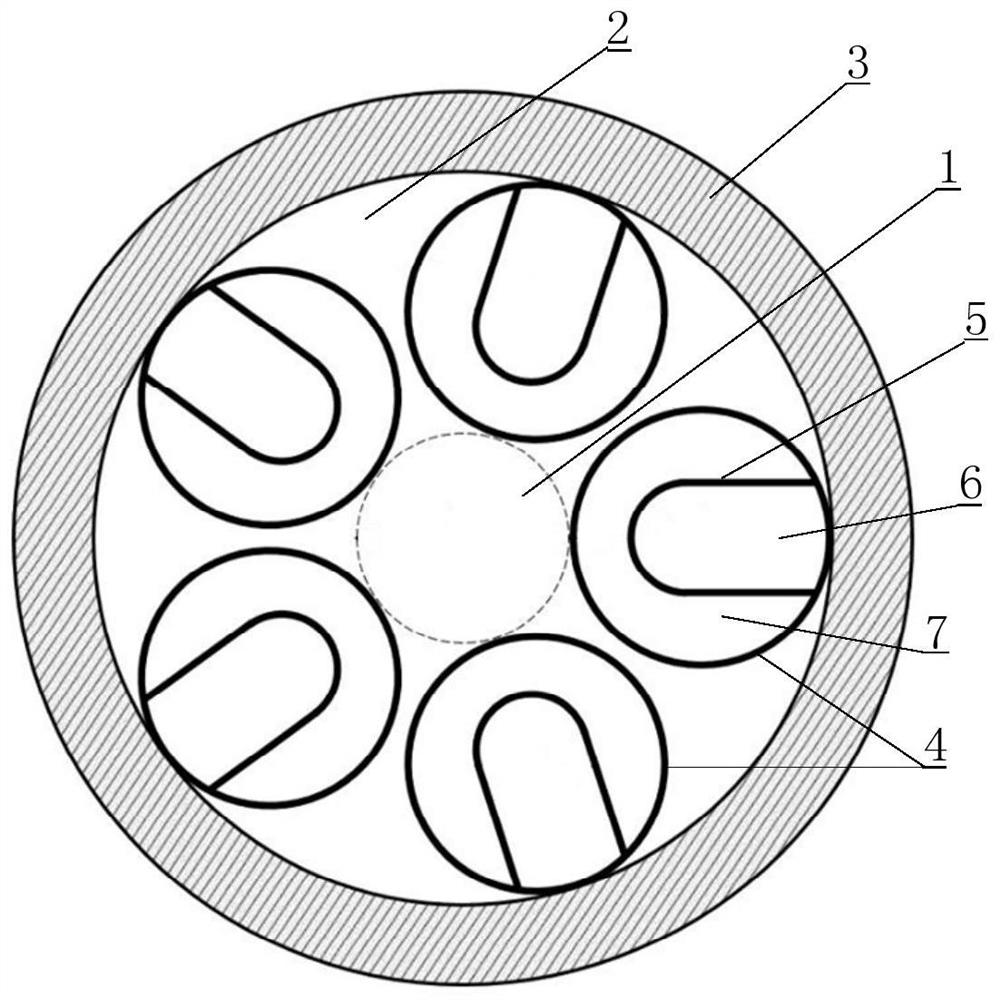

Embodiment 1

[0052] Such as Figure 4 As shown, assuming that the target transmission band is 1.2-2 μm, the target transmission window (i.e. bandwidth) is 800 nm, and the loss is reduced as much as possible, the first set of parameters can be selected as: the diameter D of the core region 1 = 40 μm, the number of capillaries 4 N=5, the gap g between any two adjacent capillaries 4=3.3μm, according to physical characteristics, the longer the wavelength, the greater the loss of the fiber, so the anti-resonance center needs to shift to the long-wavelength direction, and the anti-resonance center Wavelength λ is set as 2.1 μm, can obtain the tube wall thickness of capillary 4 and the thickness t=0.5 μm of U-shaped glass structure 5 by formula (1), can obtain the radius R=24 μm of capillary 4 by formula (2), Then the distance z=10.5 μ m between the curved end of the desirable U-shaped glass structure 5 and the capillary 4 warp direction separation, the curved end radius r=8.6 μm of the U-shaped ...

Embodiment 2

[0057] Such as Figure 4 As shown, assuming that the target transmission band is 1.5-2μm, and the target transmission window (i.e. bandwidth) is 500nm, if you want to have a good single-mode characteristic while having a wide bandwidth and low loss, you can choose the second set of parameters: core area 1 diameter D=40 μm, the number of capillary tubes 4 N=5, the gap g=3.3 μm between any two adjacent capillary tubes 4, according to physical characteristics, the longer the wavelength is, the greater the loss of the optical fiber is, so the anti-resonance center needs Offset to the long wavelength direction, the anti-resonance center wavelength λ is set to 2.1 μm, the tube wall thickness of the capillary 4 and the thickness t=0.5 μm of the U-shaped glass structure 5 can be obtained by the formula (1), and the formula (2) can Find the radius R=24 μ m of capillary 4, then the distance z=10 μ m that the curved end of desirable U-shaped glass structure 5 is separated from capillary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com