High-frequency converter applied to PSM high-voltage power supply and PSM high-voltage power supply

A high-voltage power supply and high-frequency conversion technology, which is used in high-efficiency power electronic conversion, output power conversion devices, conversion of AC power input to DC power output, etc., to achieve the effects of improving stability, improving power grid quality, and simple winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

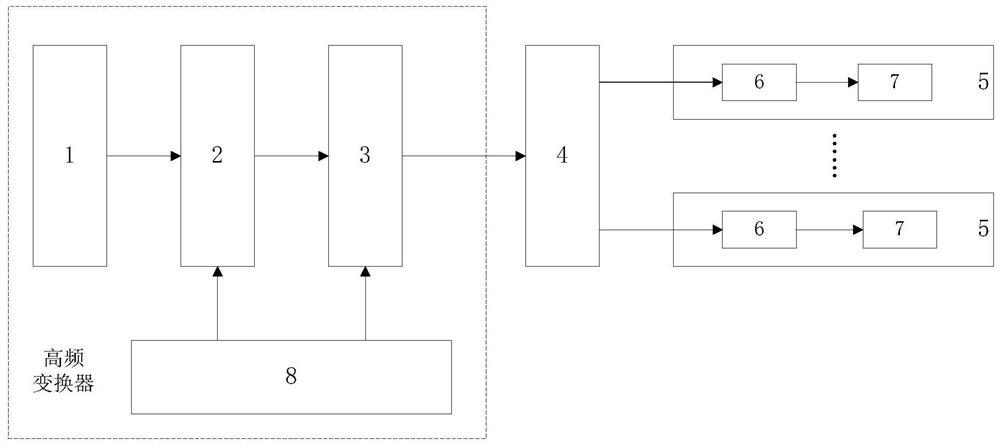

[0044] Compared with the pre-stage energy supply of the existing PSM high-voltage power supply, which mainly adopts a topology structure composed of a low-frequency three-phase power-frequency full-wave rectifier circuit and a low-frequency three-phase multi-winding transformer, it has the advantages of heavy weight, large volume, and poor control accuracy. Low, large output ripples and other issues, this embodiment proposes a high-frequency converter that can be modularized and applied to PSM high-voltage power supplies, and is constructed using high-frequency inverter technology, specifically as figure 1 As shown, the high-frequency converter of this embodiment is mainly composed of a three-phase EMI filter circuit 1 , a controllable rectification circuit 2 , a soft-switching inverter circuit 3 , and a DSP and ARM control circuit 8 .

[0045] Among them, the three-phase EMI filter circuit 1 is used to denoise the three-phase alternating current, and input the processed three-...

Embodiment 2

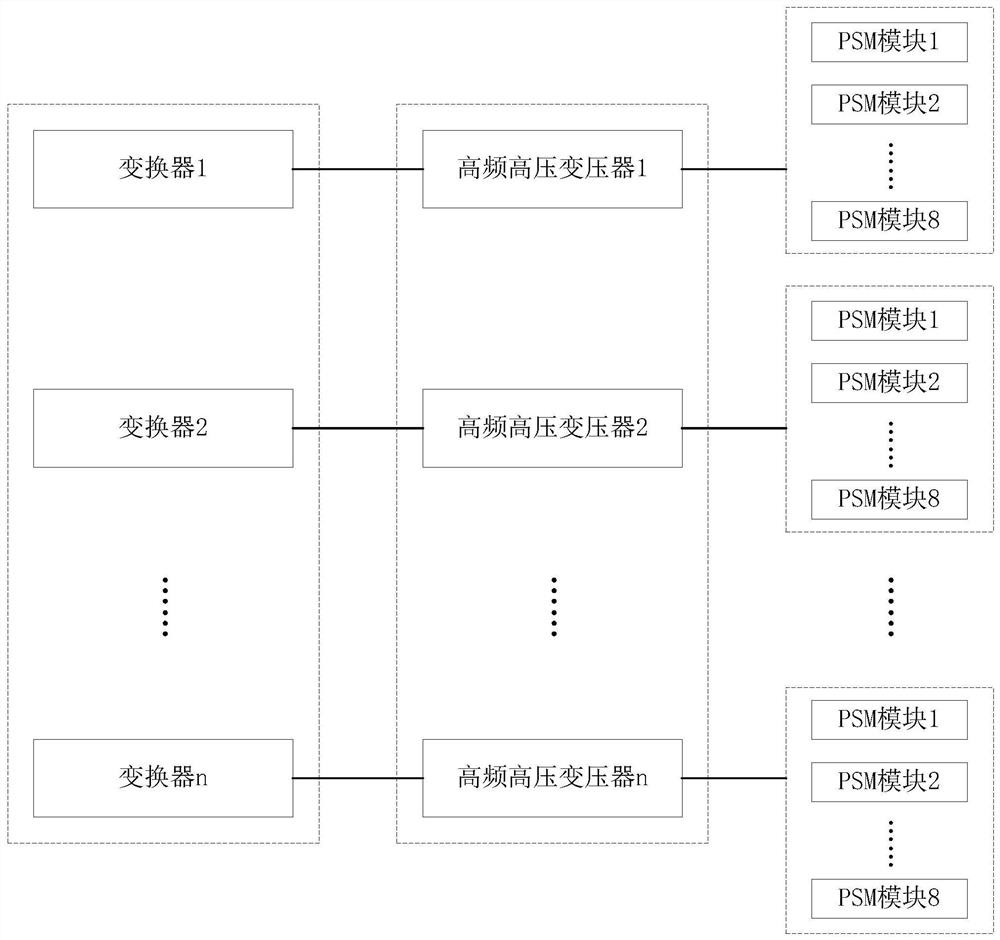

[0055] Based on a plurality of high-frequency converters proposed in Embodiment 1 above, a modular architecture with an average power of hundreds of kilowatts can be jointly realized, and the pre-stage energy supply of the PSM high-voltage power supply can be jointly provided.

[0056] Specific as figure 2 As shown, the present embodiment proposes a PSM high-voltage power supply, including n high-frequency converters proposed in the above-mentioned embodiment 1, n high-voltage high-frequency transformers 4 and n PSM module groups; wherein, the value of n is based on the output The level of voltage is determined by dividing 5~6kV into a module group (in this embodiment, the value of n is determined by dividing the highest output voltage of the PSM high-voltage power supply by (5~6kV), and n is a positive integer); .

[0057] Each PSM module group includes a plurality of PSM modules 5, and the output terminals of the plurality of PSM modules 5 are connected in series to realiz...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap