Method for preparing ZSM-22 molecular sieve

A technology of molecular sieves and templates, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the narrow synthesis phase area, the application limitation of ZSM-22 molecular sieve, and the difficulty in synthesizing ZSM-22 molecular sieve nanosheets and other problems, to achieve the effect of not easy to deposit carbon and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Dissolve 3.72 grams of 1-ethylpyridinium bromide, 0.06 grams of sodium aluminate, 0.5 grams of sodium hydroxide and 0.4 grams of urea in 15.5 grams of deionized water, slowly add 10 grams of silica sol under stirring conditions, and continue stirring for one hour Put it into a stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallize at 150°C for 4 days. After the crystallization is completed, filter, wash and dry to obtain ZSM-22 molecular sieve.

[0043] The material ratio (molar ratio) of the reactants is: SiO 2 / Al 2 o 3 =180; 1-ethylpyridinium bromide / SiO 2 = 0.3; OH - / SiO 2 =0.2;H 2 O / SiO 2 =18; urea / SiO 2 = 0.1.

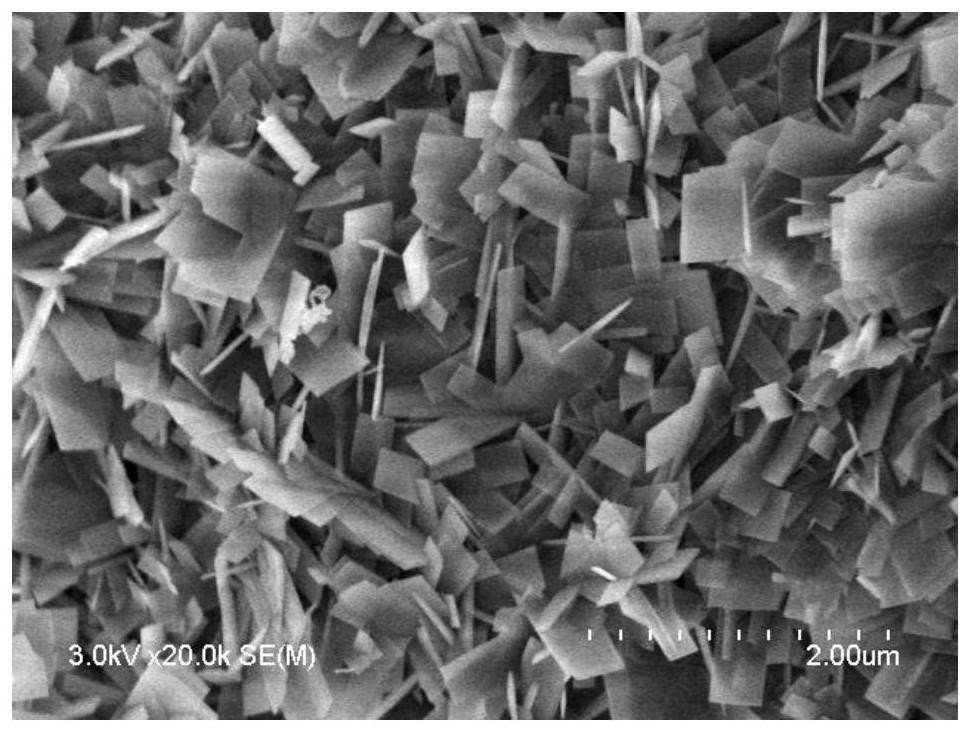

[0044] The SEM photograph of the ZSM-22 molecular sieve that embodiment 1 makes is as figure 1 As shown, its average thickness is about 10 nanometers, and the flaky crystals are randomly interlaced rather than stacked together regularly. The silicon-aluminum ratio of the molecular sieve nanosheet is 145.

Embodiment 2

[0046] In addition to the material ratio (molar ratio) of the reactants is: SiO 2 / Al 2 o 3 =100; 1-ethylpyridinium bromide / SiO 2 = 0.5; OH - / SiO 2 =0.1;H 2 O / SiO 2 =20; urea / SiO 2 Except =0.1, all the other are with embodiment 1.

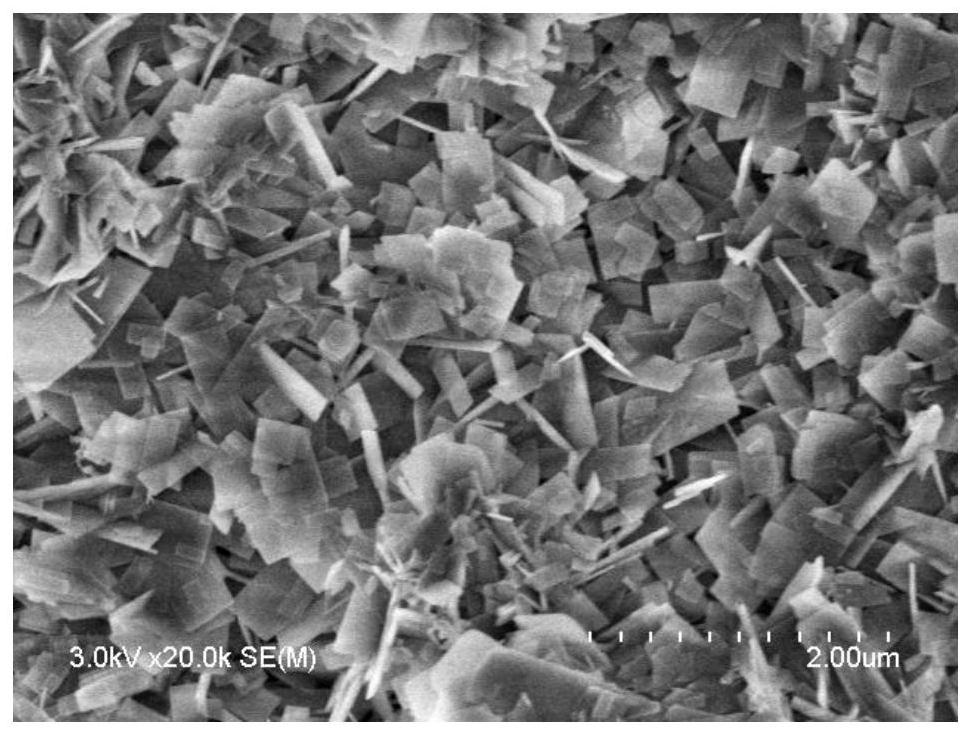

[0047] The SEM photograph of the ZSM-22 molecular sieve that makes is as figure 2 As shown, the average thickness is 10 nm, and the silicon-aluminum ratio is 101.

Embodiment 3

[0049] In addition to the material ratio (molar ratio) of the reactants is: SiO 2 / Al 2 o 3 =20; 1-ethylpyridinium bromide / SiO 2 = 0.3; OH - / SiO 2 =0.2;H 2 O / SiO 2 =18; urea / SiO 2 Except =0.1, all the other are with embodiment 1.

[0050] The prepared ZSM-22 molecular sieve has an average thickness of 15 nanometers and a silicon-aluminum ratio of 17.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com