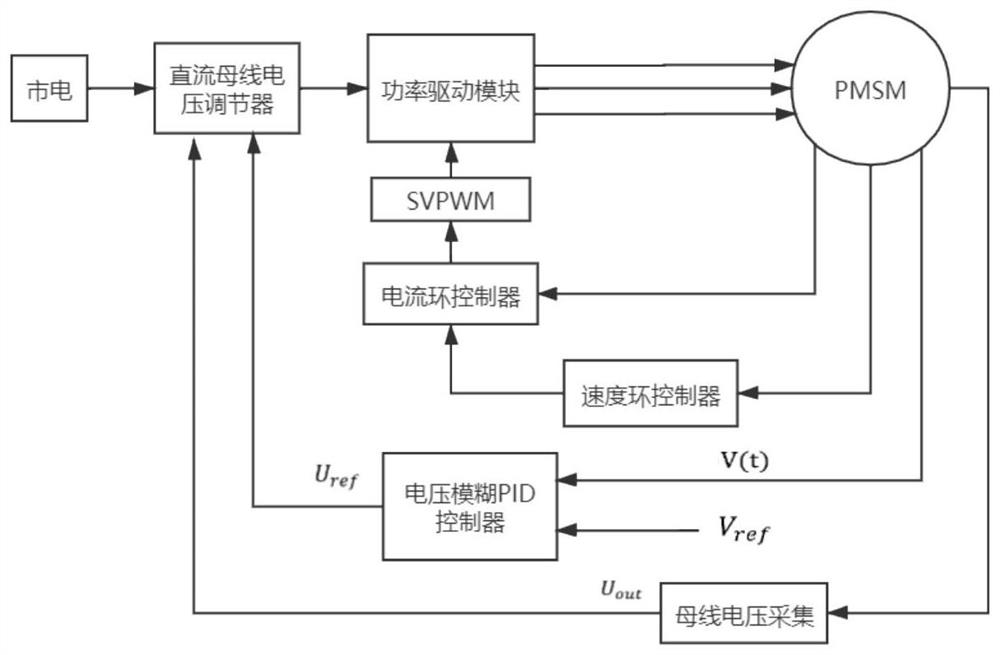

Motor driving system based on bidirectional interleaved parallel DC-DC inverter

A DC-DC and inverter technology, applied in the field of motor drive systems based on bidirectional interleaved parallel DC-DC inverters, can solve the problems affecting the output accuracy and stability of the drive system, large on-off time and dead time, etc. The problem of large motor current ripple, etc., achieves the effect of low cost, simple topology structure and small conduction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

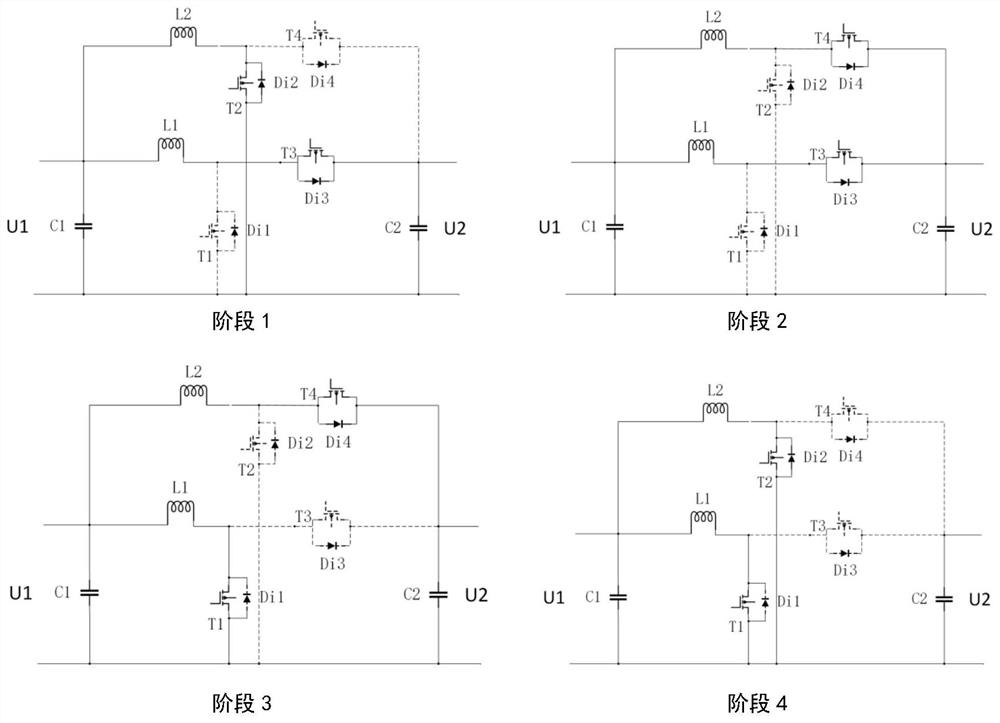

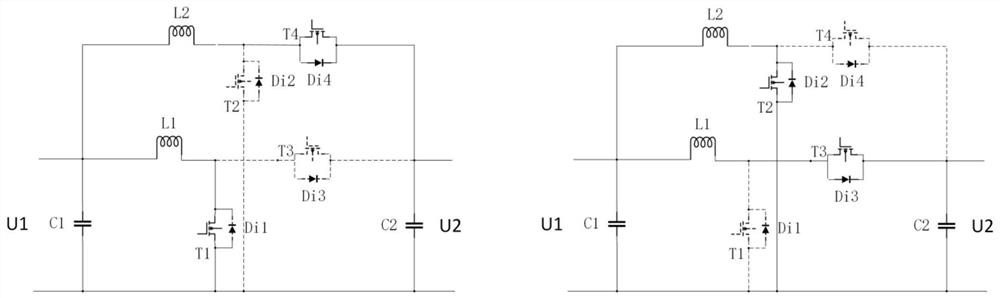

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0033] The final output instantaneous torque of AC permanent magnet synchronous motor includes basic electromagnetic torque and cogging torque. The present invention focuses on solving the torque ripple caused by the electromagnetic torque. This part of the torque ripple is caused by two factors. One is the interaction between the stator current harmonic and the rotor magnetic field harmonic; It is caused by the reluctance torque generated by the unequal shaft inductance. Since the present invention adopts d-axis current Id=0 control, the reluctance torque is 0. Therefore, this method will improve the control effect from the perspective of solving the torque ripple generated by the stator current harmonics.

[0034] The harmonic interaction of the same order of the potential and the stator current produces the average output torque of the motor, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com