Natural honey grass jelly and preparation process thereof

A technology of natural honey and honey, which is applied in the direction of food science, etc., can solve problems affecting health, etc., and achieve the effect of improving taste, improving immunity, and improving product quality and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

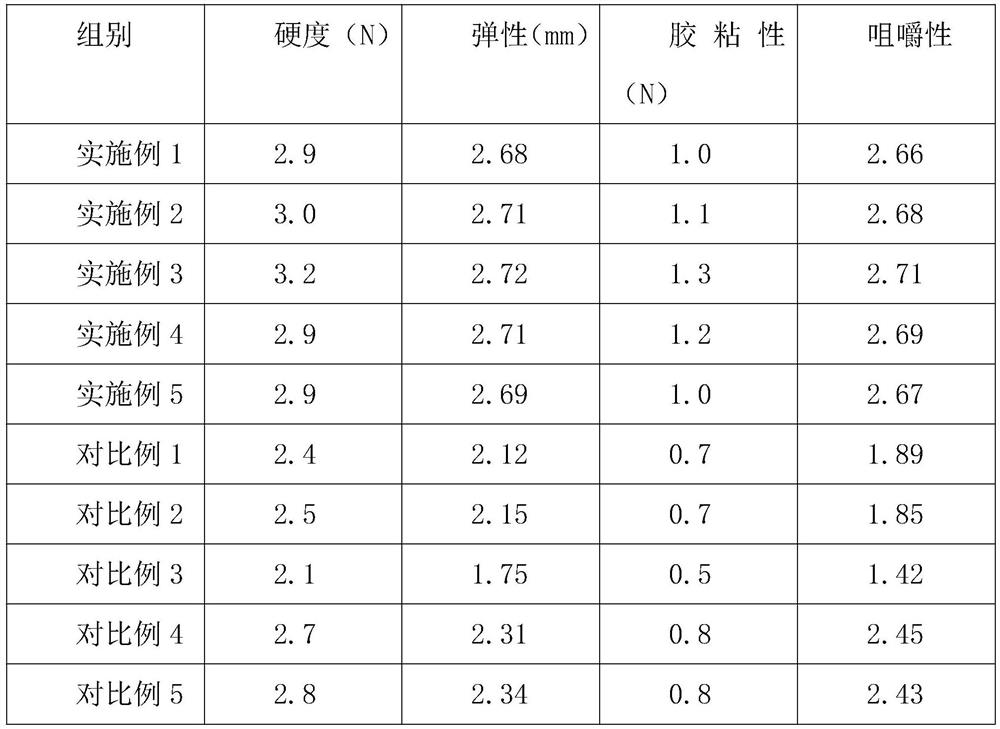

Examples

Embodiment 1

[0030] First prepare the following raw materials by weight: 30 parts of dried jelly, 5 parts of hawthorn, 4 parts of green bark, 1 part of tamarind, 5 parts of fermented sorghum mixture, 4 parts of myrobalan extract, 1 part of tribulus extract, and 2 parts of honey , 1 part of vegetable oil, 1 part of modified starch, 0.4 part of sodium alginate, 0.1 part of preservative, then wash the hawthorn, remove the seeds, soak for 8 hours, and then crush and grind together with the mixture of green skin, tamarind and fermented sorghum to obtain pulp Put the dry jelly grass into water with 2 times the weight, take out the jelly grass after boiling in the pot for 30 minutes, boil the liquid for later use, wash the jelly grass with water with 3 times the weight, and wash it The liquid is extracted, the eluate is mixed with the boiled liquid, and the mixed liquid is obtained after filtration; the slurry, the mixed liquid, the extract of Myrobalan, the extract of Tribulus terrestris, vegetab...

Embodiment 2

[0043] First prepare the following raw materials by weight: 33 parts of dried jelly, 6 parts of hawthorn, 5 parts of green bark, 2 parts of tamarind, 6 parts of fermented sorghum mixture, 5 parts of myrobalan extract, 2 parts of tribulus extract, and 3 parts of honey , 1.3 parts of vegetable oil, 1.5 parts of modified starch, 0.5 parts of sodium alginate, 0.2 parts of preservatives, then wash the hawthorn, remove the seeds, soak for 9 hours, and then crush and grind together with the mixture of green skin, tamarind and fermented sorghum to obtain pulp Put the dry jelly grass into water with 2 times the weight, take out the jelly grass after 32 minutes of boiling in the pot, boil the liquid for later use, wash the jelly grass with water with 3 times the weight, and wash it The liquid is extracted, the eluate is mixed with the boiled liquid, and the mixed liquid is obtained after filtration; the slurry, the mixed liquid, the extract of Myrobalan, the extract of Tribulus terrestri...

Embodiment 3

[0056] First prepare the following raw materials by weight: 35 parts of dried jelly, 8 parts of hawthorn, 7 parts of green bark, 3 parts of tamarind, 7 parts of fermented sorghum mixture, 7 parts of myrobalan extract, 3 parts of tribulus extract, and 4 parts of honey , 1.5 parts of vegetable oil, 2 parts of modified starch, 0.6 parts of sodium alginate, 0.3 parts of preservatives, then wash the hawthorn, remove the seeds, soak for 10 hours, and then crush and grind together with the mixture of green skin, tamarind and fermented sorghum to obtain pulp Put the dry jelly grass into water with 2 times the weight, take out the jelly grass after boiling in the pot for 35 minutes, boil the liquid for later use, wash the jelly grass with water with 3 times the weight, and wash it The liquid is extracted, the eluate is mixed with the boiled liquid, and the mixed liquid is obtained after filtration; the slurry, the mixed liquid, the extract of Myrobalan, the extract of Tribulus terrestri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com