Composite glass fiber cloth with good flame retardance and preparation method thereof

A technology of composite glass fiber cloth and flame retardancy, which is applied in the field of composite glass fiber cloth and its preparation, can solve the problems of poor fire resistance and flame retardancy of composite glass fiber cloth, and achieve the effect of increasing escape time and ensuring life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

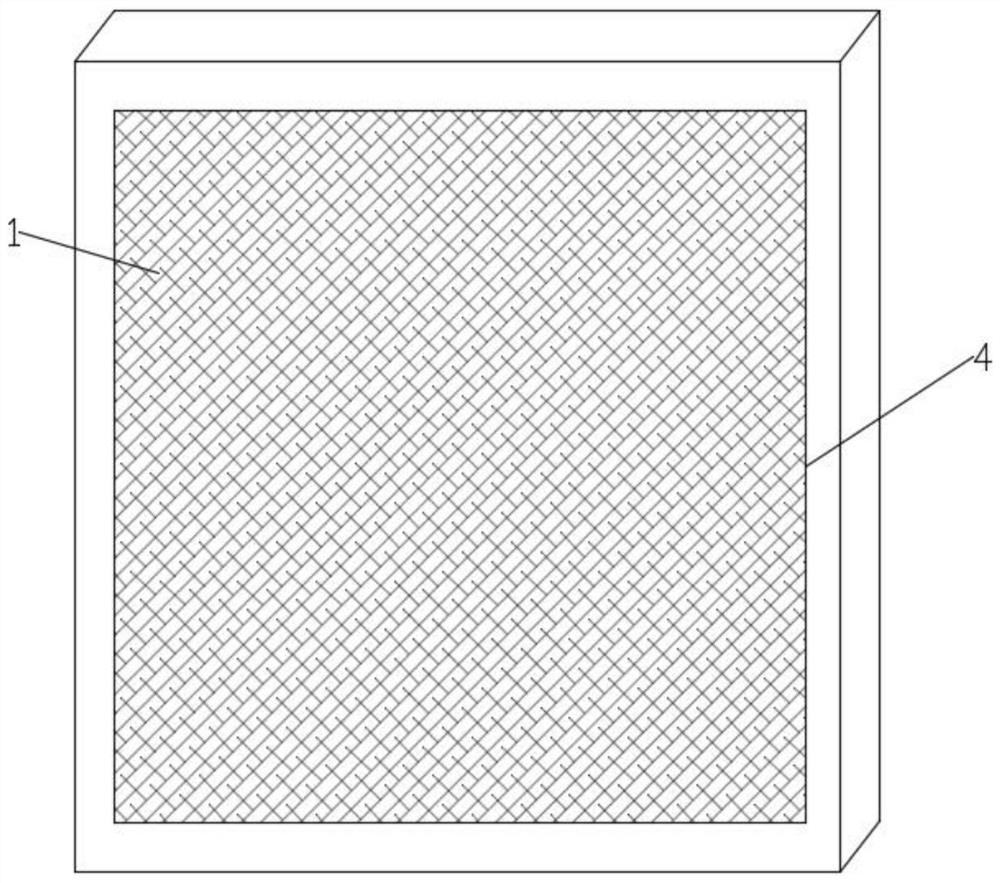

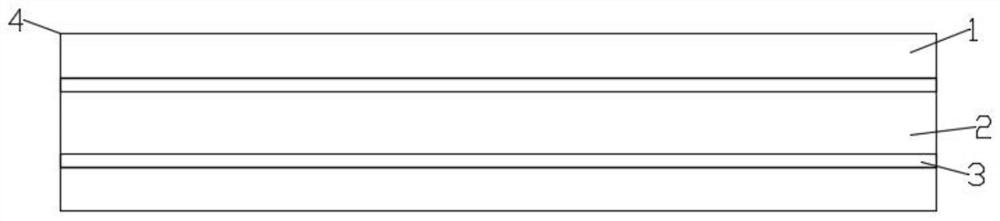

[0019] Such as Figure 1~2 As shown, in the embodiment of the present invention, a composite glass fiber cloth with good flame retardancy includes a main body 4, a buffer layer 2 for protecting the main body 4 is provided in the middle of the main body 4, and the two sides of the buffer layer 2 are symmetrical A fireproof layer 1 is provided for fireproofing, the fireproof layer 1 and the buffer layer 2 are connected by an adhesive layer 3, and the side of the fireproof layer 1 away from the buffer layer 2 is provided with a coating layer;

[0020] The fire-proof layer 1 is made of fiberglass cloth, and the setting of the fire-proof layer 1 can play the role of fire prevention and flame retardancy;

[0021] The coating layer is made of PU polyurethane material;

[0022] The material of the buffer layer 2 is made of PU foam material, and the PU polyurethane buffer foam can well perform buffering and shock absorption functions, and at the same time, the buffer layer 2 and the f...

Embodiment 2

[0025] A kind of preparation method based on the good composite glass fiber cloth of flame retardancy described in embodiment 1, the steps are as follows:

[0026] S1. Put the fireproof layer 1 on the polyurethane coating equipment, then turn on the polyurethane coating equipment, coat the polyurethane on the outer surface of the fireproof layer 1, and use a scraper to clean the outer surface of the fireproof layer 1 after coating;

[0027] S2. Coating the adhesive layer 3 on the upper surface of the buffer layer 2, then placing the adhesive layer 3 on the calender, placing a layer of fireproof layer 1 on the upper and lower substrate frames of the calender, and mixing the evenly stirred adhesive layer 3 Coating on the buffer layer 2, and then pressing the fireproof layer 1 and the buffer layer 2 together;

[0028] S3. After the pressing is completed, put the finished product into an oven for baking and curing. The oven baking time is five minutes, and the baking temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com