Recyclable modular fixed bed bio-membrane reactor

A biofilm reactor and fixed bed technology, applied in the field of water treatment, can solve the problems of difficult control of aeration, high installation cost, and difficult cleaning, so as to achieve rapid installation effect, improve efficiency, avoid waste and production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

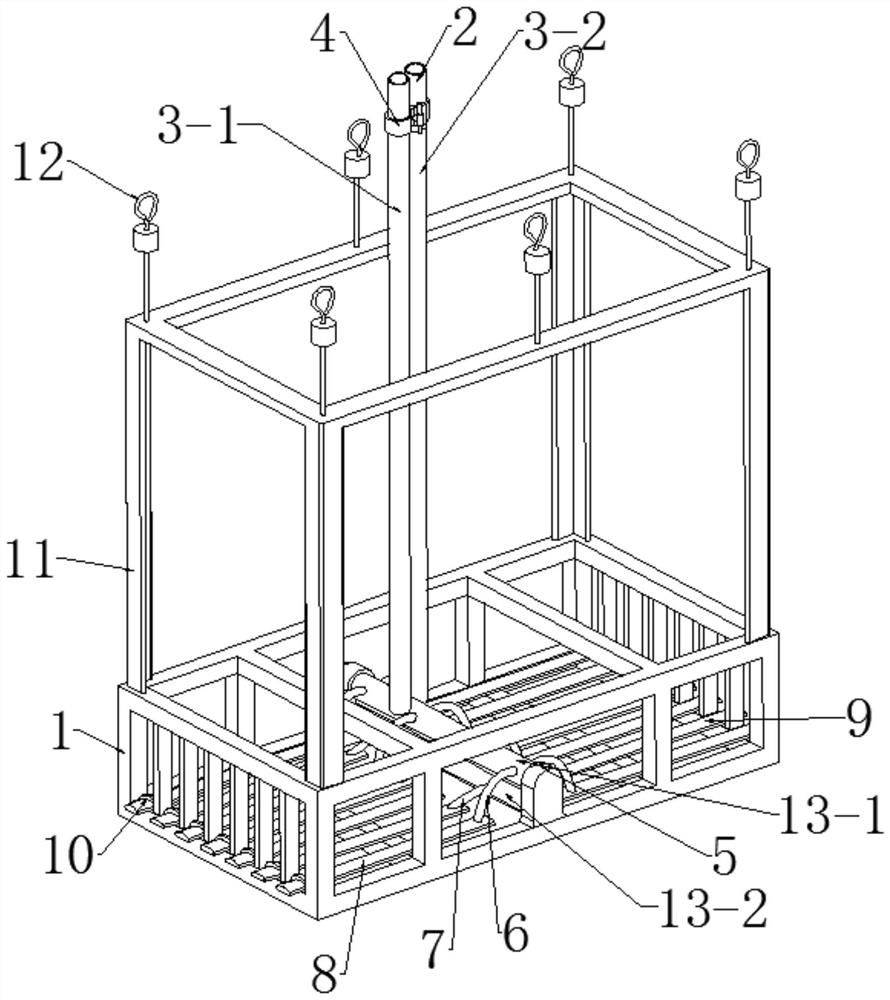

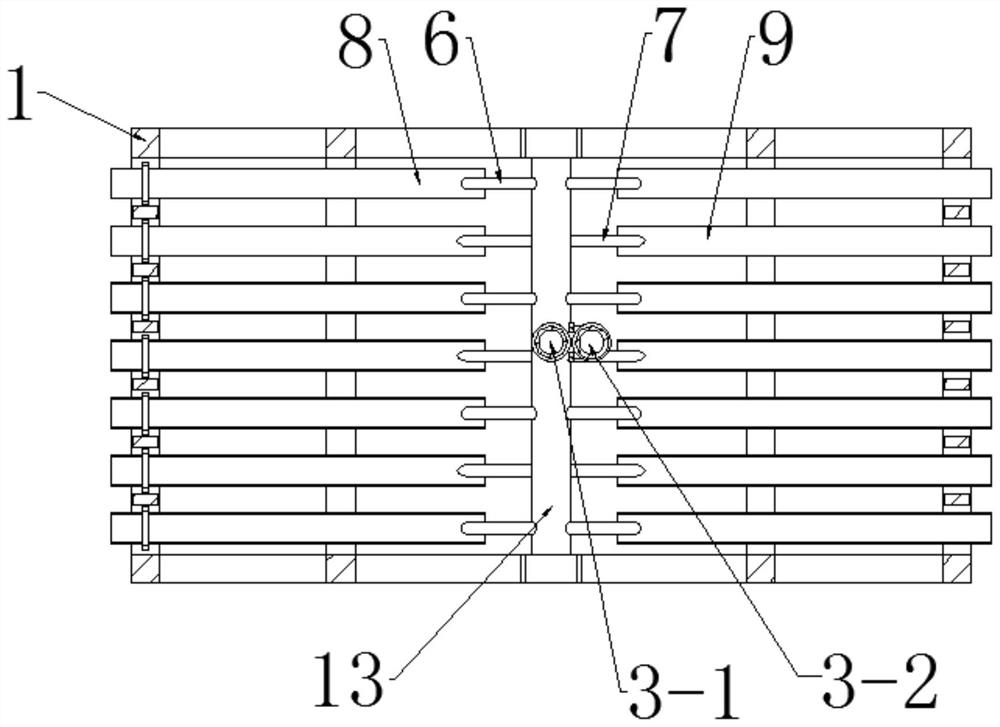

[0012] Specific Embodiment 1: The recyclable modular fixed bed biofilm reactor in this embodiment includes a fixed frame 1, two external pipes 2, an internal pipe, a fixed seat 5, a plurality of first delivery pipes 6, and a plurality of second delivery pipes 7. A plurality of first aeration pipes 8, a plurality of second aeration pipes 9 and the main pipe, the fixed frame 1 is a cuboid frame structure, and the two ends of the main pipe 13 are fixedly connected to the fixed frame 1 through the fixed seat 5 On the bottom frame of the main pipe 13, the first main pipe 13-1 and the second main pipe 13-2 are arranged in parallel and spaced along the height direction, and a plurality of first aeration pipes are respectively arranged on the left and right sides of the main pipe 13 8 and a plurality of second aeration pipes 9, the first aeration pipe 8 and the second aeration pipe 9 on each side are arranged alternately, the first main pipe 13-1 passes through the first delivery pipe ...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that the microbial carrier filler is placed inside the fixing frame 1 .

[0016] In this embodiment, fixed filler is filled in the fixed frame 1 .

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the fixing member 10 is sleeved on the first aeration pipe 8 and the second aeration pipe 9 to fix the first aeration pipe 8 and the second aeration pipe. Tube 9 position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com