Method for preparing electronic-grade N-methylformamide at low temperature

A technology of methyl formamide and low temperature conditions, which is applied in the field of preparation of electronic grade N-methyl formamide, which can solve the problems of increased heating conditions, equipment corrosion, excessive metal ion content, increased safety of pressure vessels, and production costs. , to achieve the effect of being suitable for large-scale industrial use, extremely fast reaction speed and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the method for preparing electronic-grade N-methylformamide under low temperature conditions involved in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026]

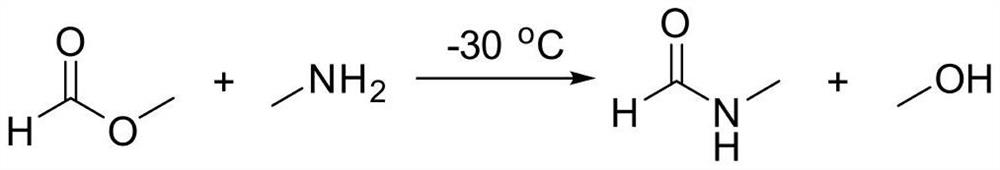

[0027] Add 30mL of methyl formate to a 100mL glass beaker, add a stirring magnet, put it in a cold trap, cool to -30°C, and then pass 12L of methylamine gas (normal temperature and pressure) into it, and the methylamine gas immediately Liquefied into methylamine liquid, and mixed with methyl formate in the liquid phase to quickly react to generate N-methylformyl and methanol; and then distilled to remove methanol to obtain pure N-methylformamide.

[0028]

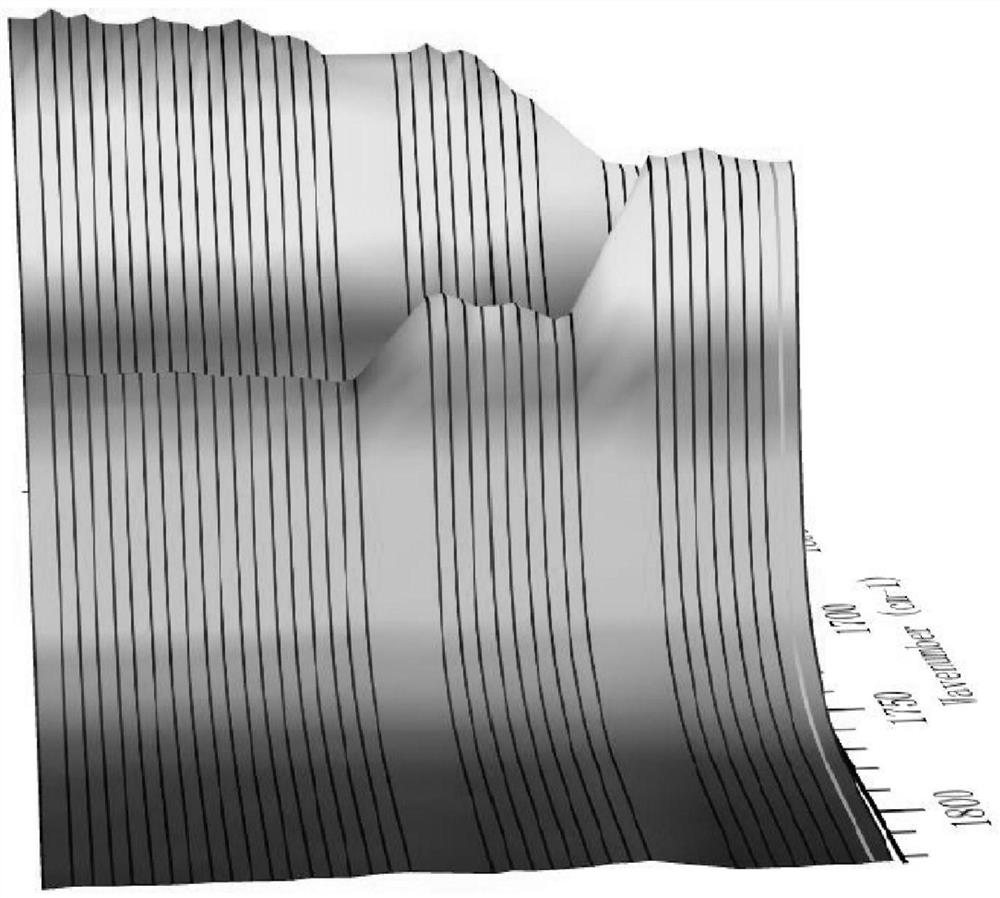

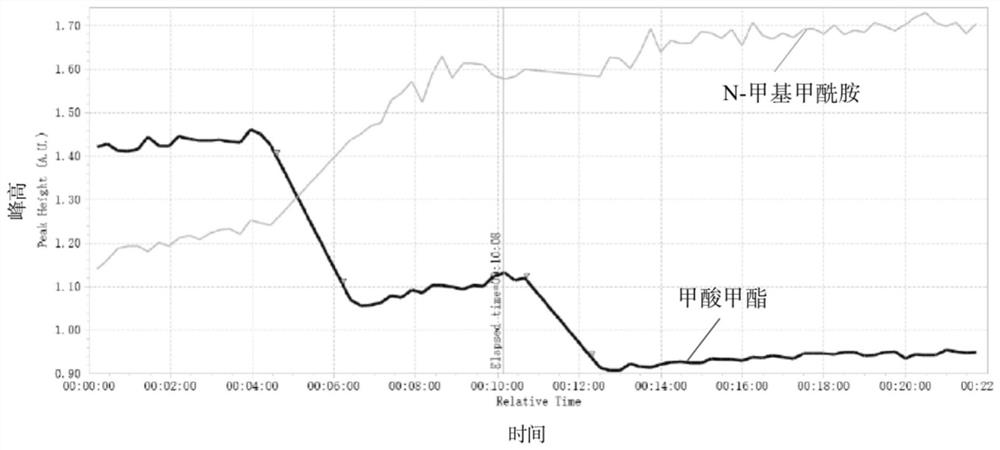

[0029] Such as figure 1 and 2 As shown, under the condition of -30°C, the online infrared spectrometer was used to monitor the reaction of methyl formate and methylamine. Will not affect the progress of the reaction.

[0030] In addition, since both methyl formate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com