Steel with bionic multi-level structure and machining process thereof

A processing technology, multi-level technology, applied in the direction of metal material coating technology, coating, manufacturing tools, etc., can solve the problems that the material strength and toughness cannot be achieved at the same time, and the nucleation resistance and long crack growth resistance cannot be achieved at the same time. Great maneuverability and variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

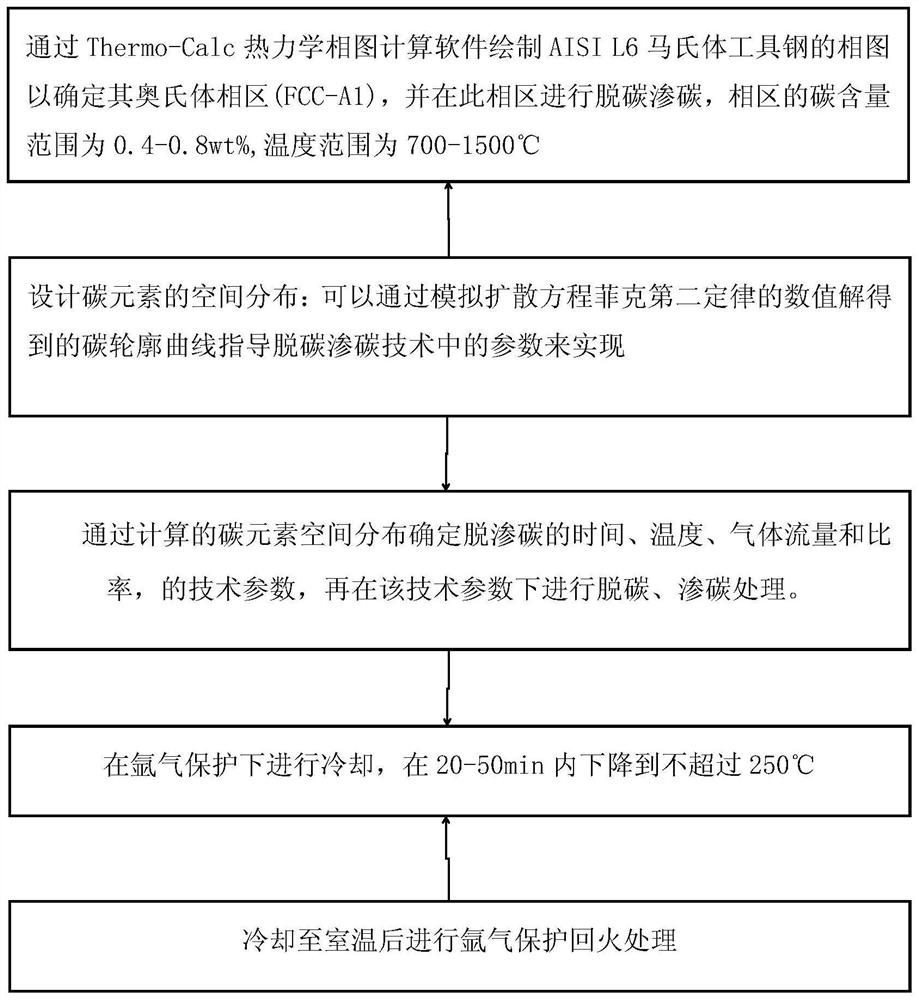

[0065] The specific operation steps are as follows:

[0066] S10: Taking AISI L6 martensitic tool steel (0.56wt%C, 1.1wt%Cr, 1.7wt%Ni0.5wt%Mo, 0.1wt%V) with a thickness of 3mm as the research object, it was changed by decarburization and carburizing technology The spatial distribution of carbon in the steel is used to control the phase transition interval, and then the microstructure of the martensitic steel is multi-layered, and finally controls the distribution of its spatial mechanical properties to meet the needs of fatigue design. This was inspired by the successful application of the multilayered structure of the human tooth under fatigue loading. Divided into the following three steps:

[0067] (1) Draw the phase diagram of AISI L6 martensitic tool steel by Thermo-Calc thermodynamic phase diagram calculation software to determine its austenite phase region (FCC_A1), and carry out decarburization and carburization in this phase region, the carbon in the phase region Th...

Embodiment 2

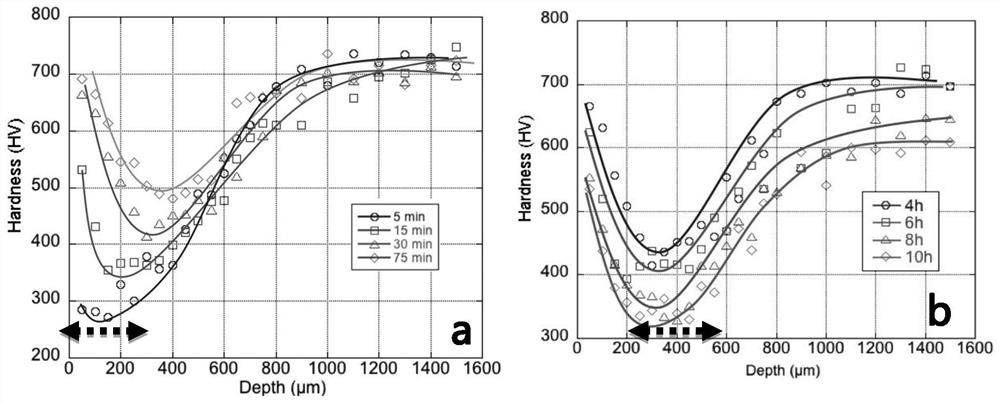

[0078] A bearing factory conducts tests with standard fatigue components. The samples used are ordinary homogeneous steel, and the width of the fatigue test site is 3mm. Its tensile strength is 1500Mpa, fatigue strength is 700Mpa, less than 50% of tensile strength.

[0079] For small-sized samples, the fatigue cycle is dominated by surface crack nucleation, so compared with homogeneous martensite, the hierarchical surface high-strength martensite layer can effectively delay fatigue crack nucleation.

[0080] Adopting the technical solution of the present invention to carry out the multi-level structure to improve the anti-fatigue performance includes the following steps:

[0081] (1) Carry out composition detection to iron and steel, confirm that carbon content is 0.5wt%, then place component in tube furnace with 500cm 3 / min into the argon to remove the air, and then heated to 930 ℃ for 10min, through 430cm 3 / min of wet hydrogen decarburization for 20h;

[0082] (2) Befor...

Embodiment 3

[0087] A bearing factory conducts tests with standard fatigue components. The samples used are ordinary homogeneous steel materials, and the width of the fatigue test site is 10mm. Its tensile strength is 1000Mpa, fatigue strength is 400Mpa, less than 50% of tensile strength.

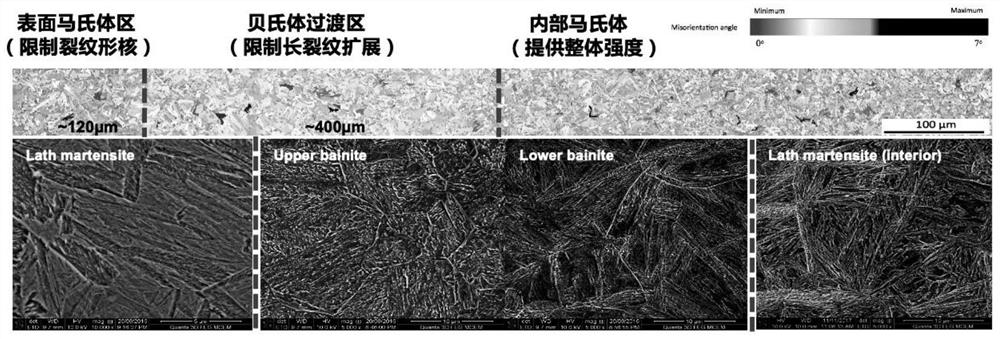

[0088] For intermediate-sized samples, the most effective strategy is to imitate the multilayer structure of teeth, forming high-strength martensite on the surface to limit crack nucleation, forming lower bainite in the middle to delay long crack growth, while maintaining martensite in the core region. body to support the bulk strength of the material,

[0089] Adopting the method of the present invention to carry out the multi-level structure to improve the anti-fatigue performance comprises the following steps:

[0090] (1) Carry out composition detection to iron and steel, confirm that carbon content is 0.6wt%C, then place component in tube furnace with 500cm 3 / min into the argon, and then heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com