Air source system of water-cooling air compressor for vehicles

A water-cooling system and compressor technology, which is applied in mechanical equipment, machines/engines, and liquid variable-capacity machinery, etc., can solve the problems of extra space installation, high exhaust temperature, and high maintenance costs, and can reduce the internal operating temperature and The effect of exhaust temperature, suppression of noise expansion, and reduction of operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

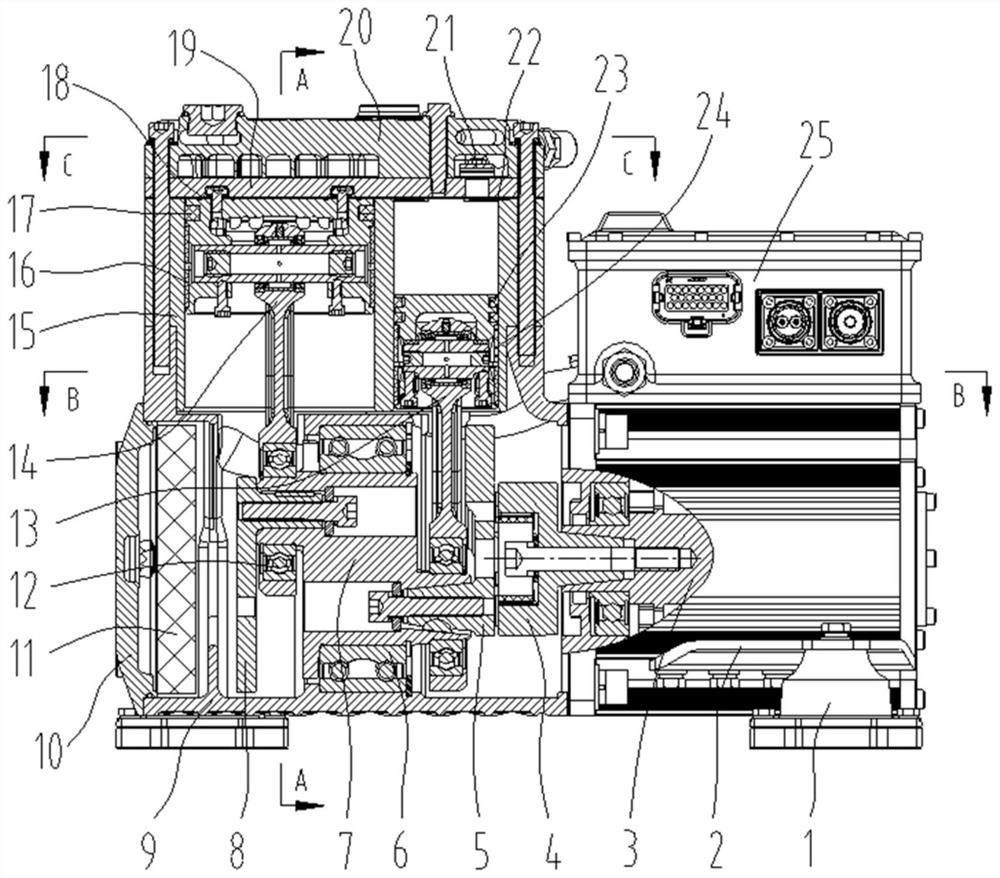

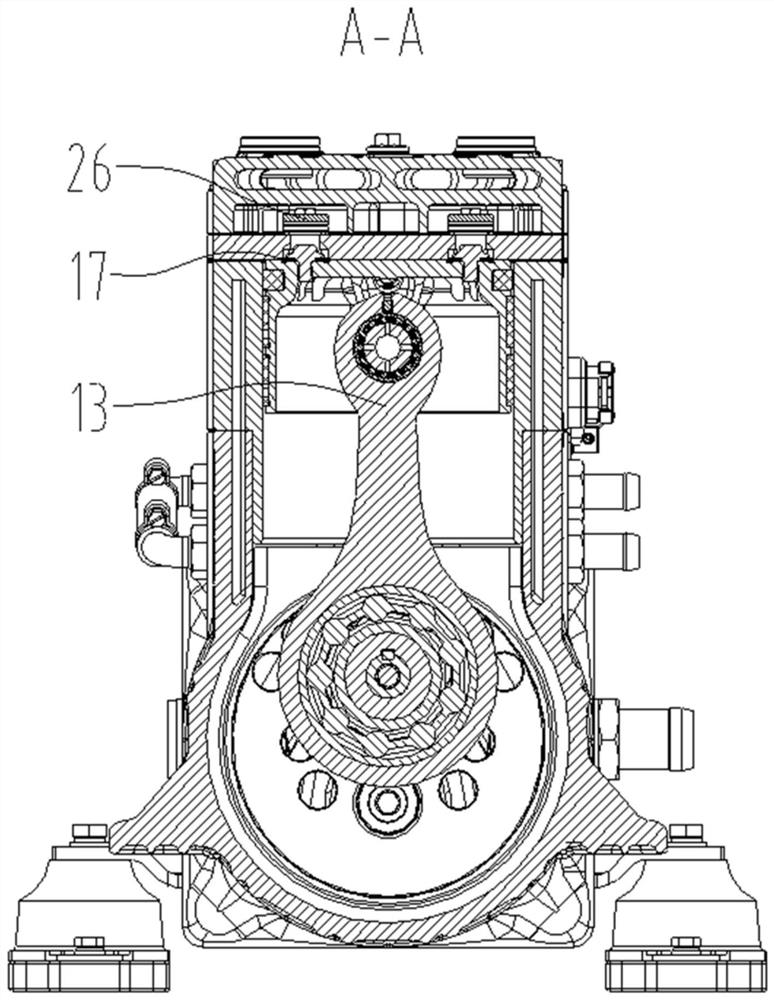

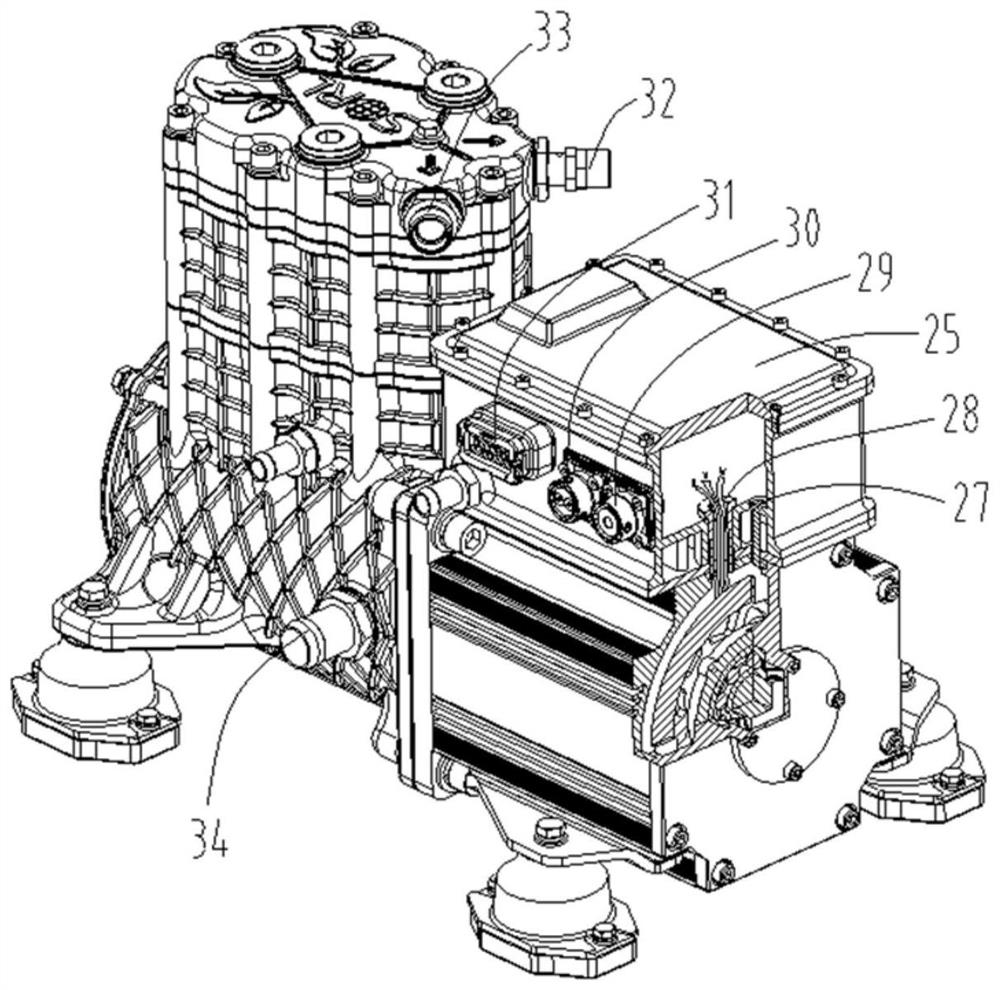

[0035] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036]The present invention provides an air source system for a vehicle water-cooled air compressor, which adopts an internally supported double-crank crankshaft 7, and is provided with a high-pressure connecting rod-piston assembly 13 and a low-pressure connecting rod-piston assembly 14 on both eccentric cranks of the crankshaft; The side crank is provided with a tapered hole, and the driven end 5 of the coupling is arranged through the fastening bolt and the key structure, and the driving end 4 of the coupling is arranged on the main shaft of the motor 3. This elastic coupling has axial and radial The deviation compensation function ensures the stable and reliable transmission of the main shaft. The motor 3 is arranged on the rear side of the crankcase 9, and the crankshaft 7 is arranged on the crankcase 9 through the maintenance-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com