Negative pressure drying device

A drying device and negative pressure technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve problems such as reducing the quality of silicon wafer finished products, and achieve the effect of good dehydration effect and good drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

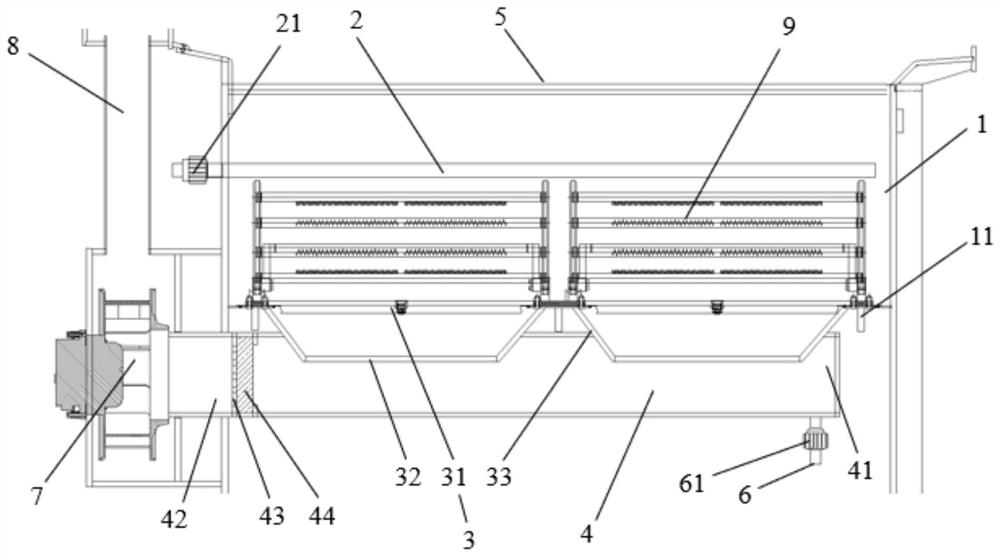

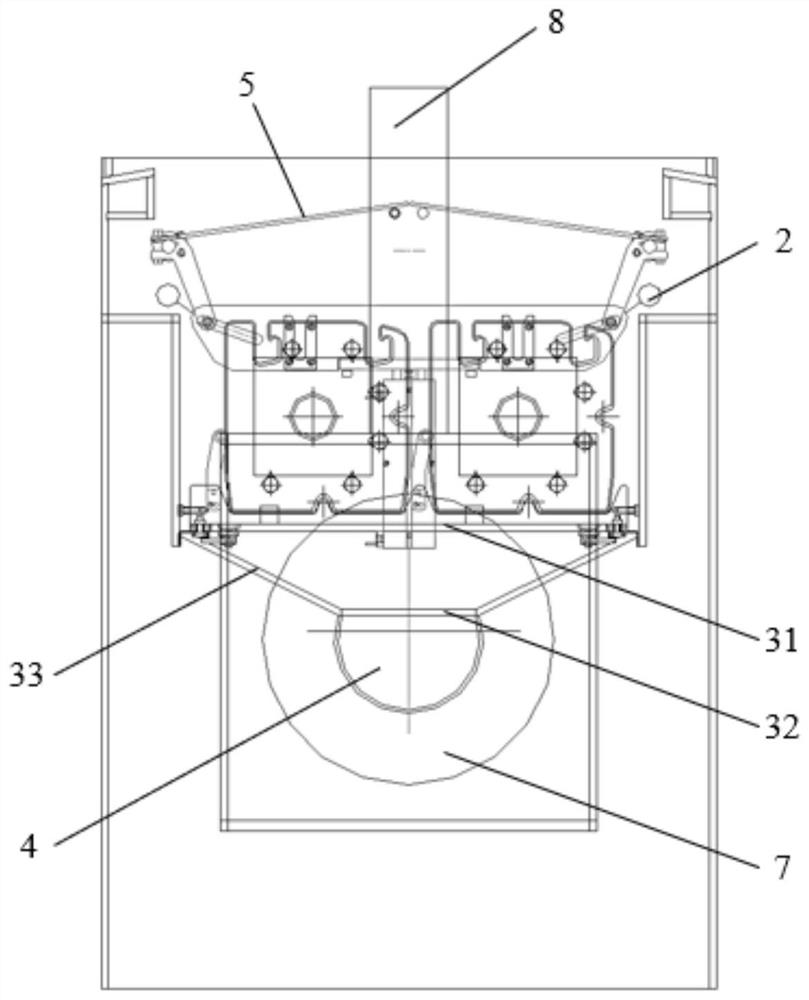

[0027] The embodiment of this specification provides a negative pressure drying device, which includes a main tank body and an exhaust air assembly, wherein the exhaust air assembly is used to form a negative pressure in the main tank body, and the exhaust air assembly can be used to store the to-be-dried parts 9 at room temperature. The surface dehydration can effectively reduce the surface moisture, avoid the generation of watermarks and other contamination, and can cooperate with other previous tanks to achieve low-temperature slow-pull cleaning, and can greatly shorten the drying time in the subsequent drying process; For example, in a possible embodiment of this specification, the negative pressure drying device is used for drying silicon wafers in electric solar cells. In the flower basket of the silicon wafer, the air exhaust component sucks the water on the surface of the silicon wafer to move downward with the airflow, so as to ensure that the watermark on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com