A model accelerated life test method for wind power main shaft bearings

An accelerated life test, wind power spindle technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., to achieve the effect of reducing test cost, shortening test cycle, and increasing load speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

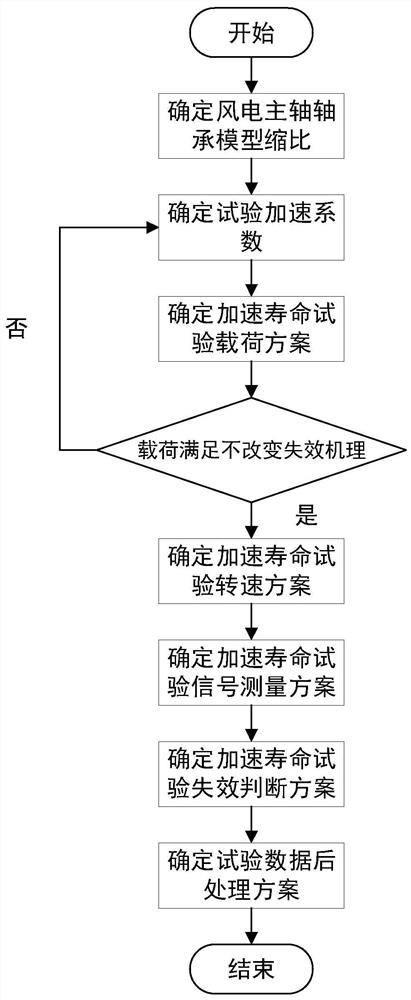

Method used

Image

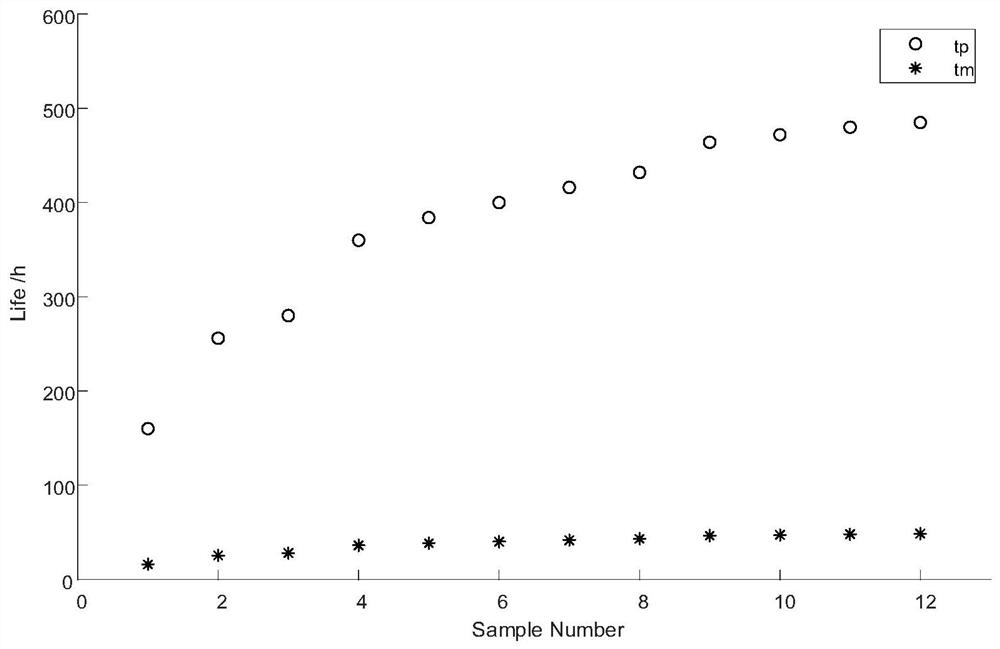

Examples

Embodiment 1

[0079] The material of the bearing ring and rolling body of a wind power main shaft bearing is set to G20Cr2Ni4A bearing steel, and the test parameters are shown in Table 1;

[0080] Table 1 Test prototype parameter table

[0081]

[0082] Due to the nature of the objective conditions of the test bench, it is difficult to realize the fatigue life test of the prototype, so a model with a reduced size ratio is used for research. Now p represents the physical quantity of the test prototype (prototype); m represents the physical quantity of the test model (model); this example Select the roller diameter as D m =6mm, geometric reduction ratio D m / D p is 0.1;

[0083] Customize the non-standard parts of the wind power main shaft bearing model according to the size reduction of the model as the experimental sample, ensure that the material of the test sample is the same as that of the prototype, the roughness is increased to Ra0.8 and above, the surface heat treatment process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com