Ultrahigh-temperature water vapor oxidation corrosion device and method for evaluating zirconium alloy coating layer

A technology of oxidation corrosion and zirconium alloy, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of difficult assembly, high cost, and difficult operation, and achieve simple installation and layout, low investment cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

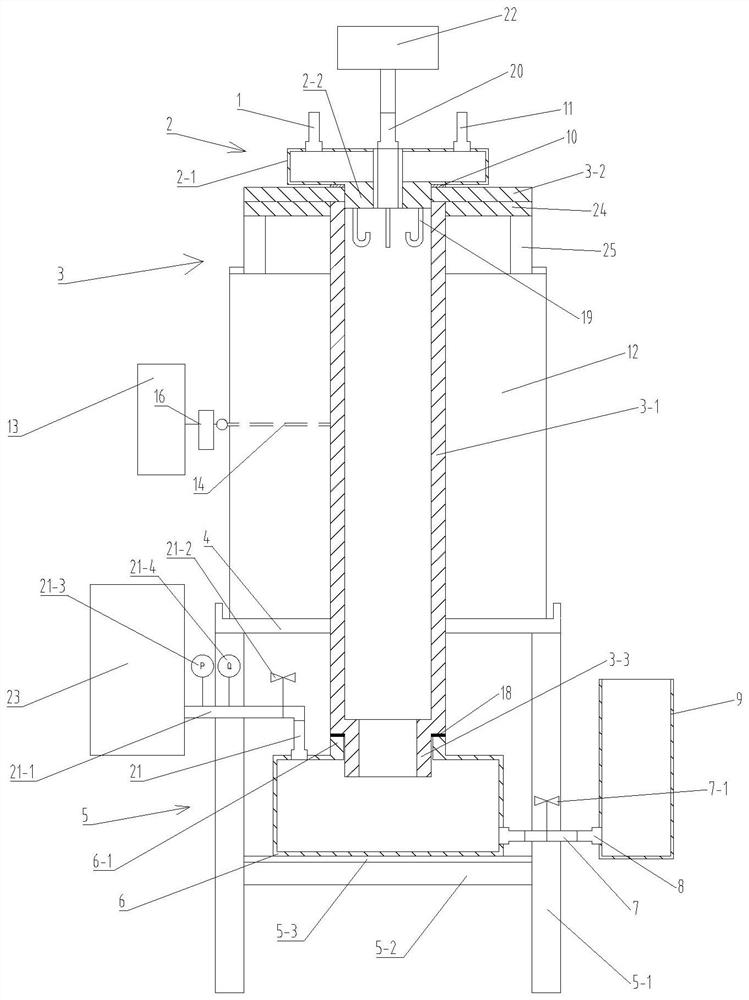

[0074] Such as figure 1 The shown is an ultra-high temperature water vapor oxidation corrosion device for evaluating zirconium alloy coatings, including a frame body, a well-type heating furnace 12 arranged on the frame body, and a steam oxidation reaction chamber arranged in the well-type heating furnace 12 3 and a water supply mechanism arranged at the bottom of the well-type heating furnace 12 and communicated with the steam oxidation reaction chamber 3, the frame body is a hollow structure;

[0075] The water supply mechanism includes a water supply tank 9 and a water storage tank 6 communicating with the water supply tank 9. The top of the water storage tank 6 is provided with an air inlet joint 21, and the air intake joint 21 is connected to an argon source through a vent pipe 21-1. 23 connection, the vent pipe 21-1 is provided with an air valve 21-2, a barometer 21-3 and a flow meter 21-4;

[0076] The steam oxidation reaction chamber 3 includes a sleeve pipe pierced i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com