Method for testing substitution degree of condensed silicon resin

A testing method and technology of silicone resin, applied in the field of silicone resin, can solve problems such as unfavorable product quality control, silicone resin structure analysis, and inability to fully represent the degree of substitution of silicone resin, so as to facilitate quality control, simplify test methods, improve efficiency and accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for testing the degree of substitution of condensation type silicone resin, comprising the steps of:

[0058] S1. After the sample to be tested is pretreated, measure and obtain the mole fraction of the inactive substituent group R, the mole fraction of the active group X, and the ratio R of the amount of the substance of the active group X to the inactive substituent group R X / R ;

[0059] Among them, the pretreatment and determination of the sample to be tested adopt the existing technology;

[0060] S2. After pre-processing the sample to be tested, measure it to obtain the mass fraction w of the silicon element in the total mass of the silicone resin Si ;

[0061] Among them, the pretreatment and determination of the sample to be tested adopt the existing technology;

[0062] S3. Bring the parameters obtained through steps S1 and S2 into formula (1) to obtain the degree of substitution P of the condensation type silicone resin of the sample to be tested ...

Embodiment 2

[0086] Based on Example 1, in this example, the test sample 1 is taken to test the degree of substitution, so as to further illustrate the technical solution of the present invention.

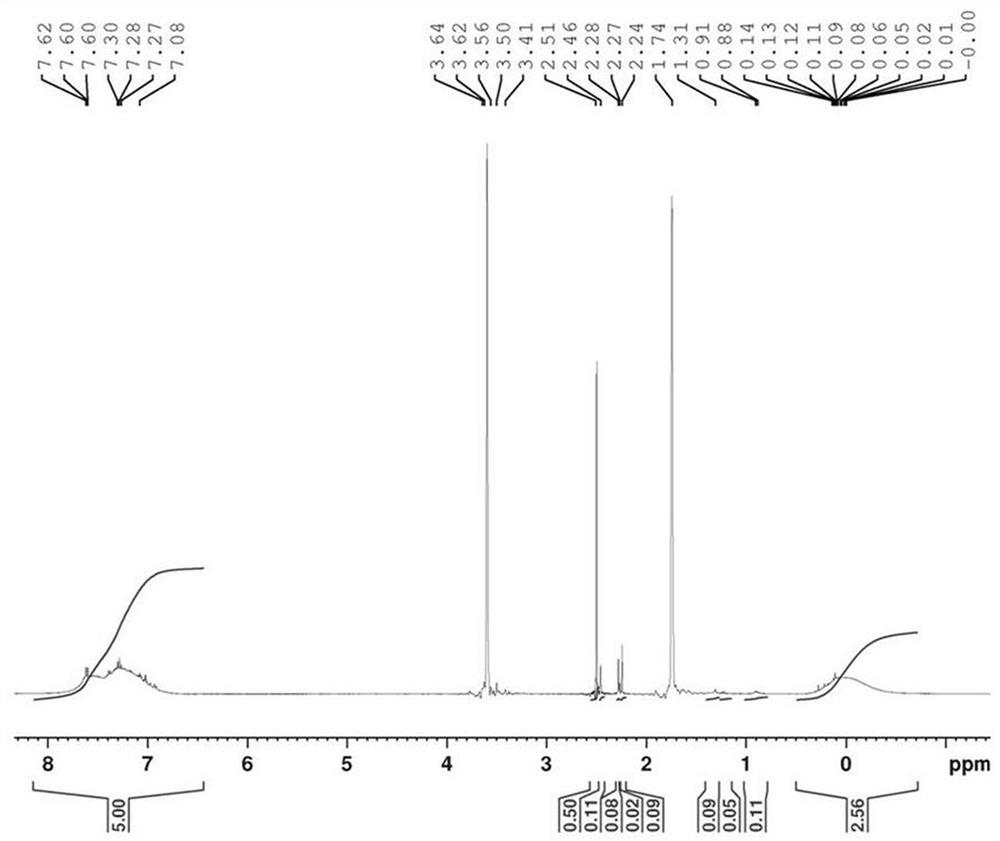

[0087] Take one drop of 0.5mL sample to be tested on a clean and dry glass slide, and let it stand and dry for 24h in a ventilated environment at (25±15)°C; then, put it in a vacuum oven, set the temperature at 50°C, The pressure is not higher than 100Pa, and it is dried for 12 hours. Take (20±2)mg dried sample to be tested and dissolve it in 0.5mL deuterated tetrahydrofuran, send the sample for 1 H NMR test (results such as image 3 shown);

[0088] With no addition of tetramethylsilane in the sample solution to be tested as the internal standard, and the solvent peak calibration, the mole fraction of each inactive substituent group R, the mole fraction of the active group X, and the active group The ratio of X to the amount of substance of the non-reactive substituent group R R X / R .

[...

Embodiment 3

[0091] Based on Example 1, the sample 2 to be tested is taken in this example to test the degree of substitution, so as to further illustrate the technical solution of the present invention.

[0092] Take 40 mg of sample 2 to be tested in a dry NMR tube, and gradually dissolve the sample to be tested in 0.5 mL of deuterated o-dichlorobenzene by solvent replacement, and send the sample for 1 H NMR test;

[0093] With no addition of tetramethylsilane in the sample solution to be tested as the internal standard, and the solvent peak calibration, the mole fraction of each inactive substituent group R, the mole fraction of the active group X, and the active group The ratio of X to the amount of substance of the non-reactive substituent group R R X / R .

[0094] Take 20g of sample 2 to be tested in a dry polytetrafluoroethylene beaker with a diameter of 80mm, and let it dry for 24h in a ventilated environment at (25±15)°C; set the temperature of the electric blast drying oven to 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com