Magnetic induction coil module

A technology of magnetic induction coils and modules, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, electrical components, etc., can solve the problems of low current resistance, difficult automation process, prone to errors, etc. Achieve the effect of reducing production costs, reducing blind connections, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention is a coil module, which can be applied to magnetic induction elements such as inductors or transformers.

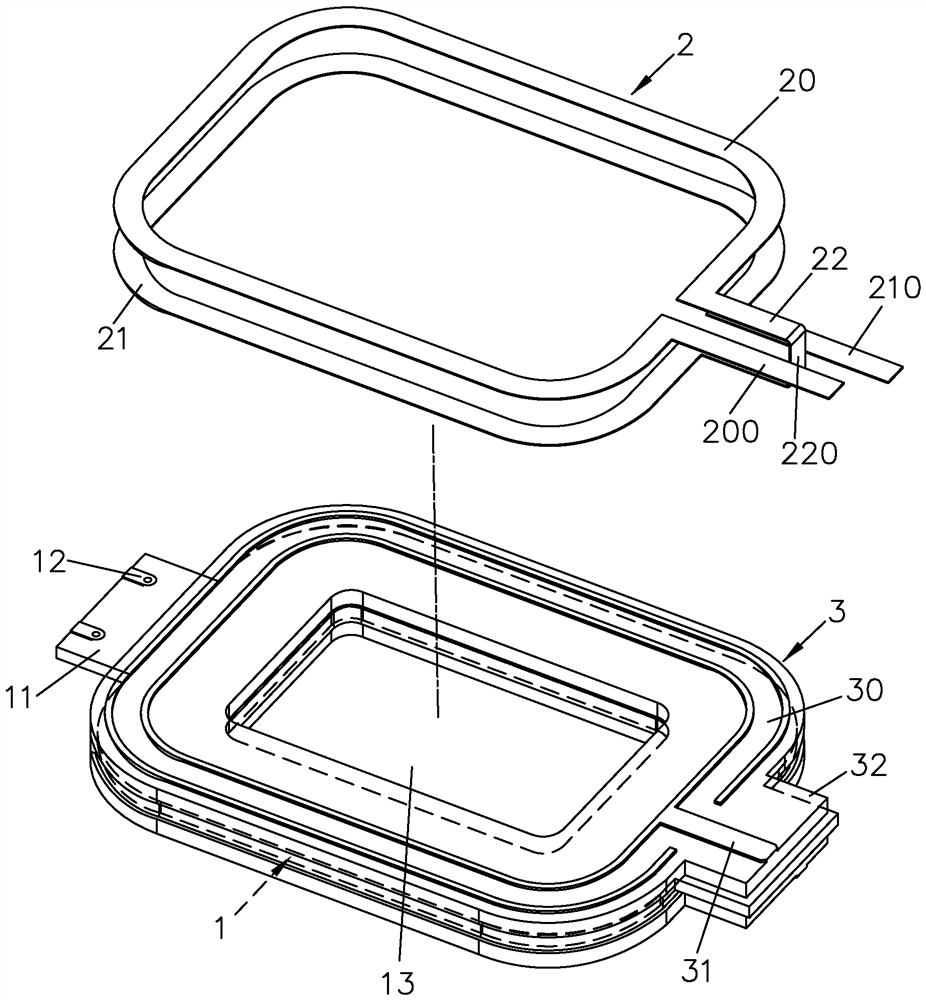

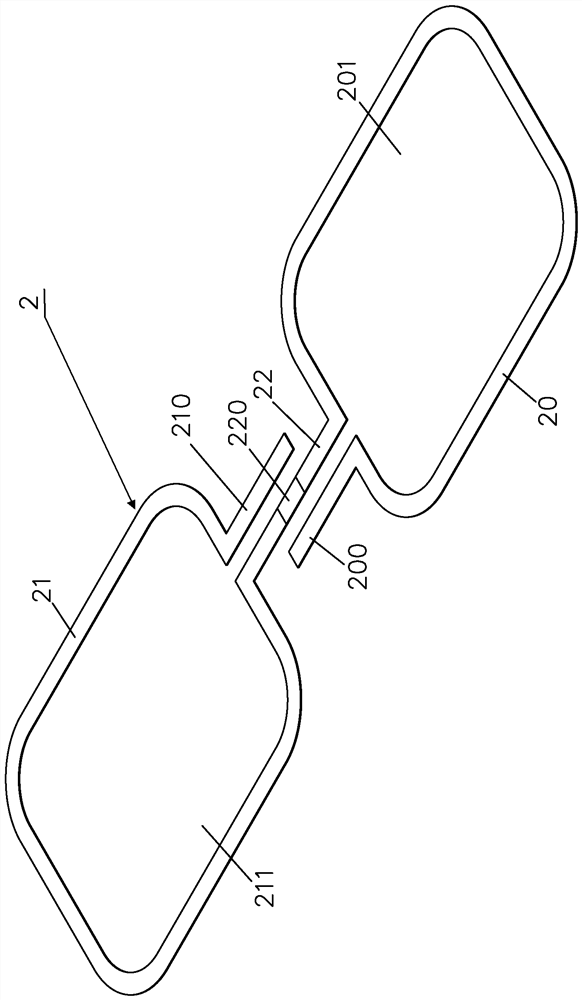

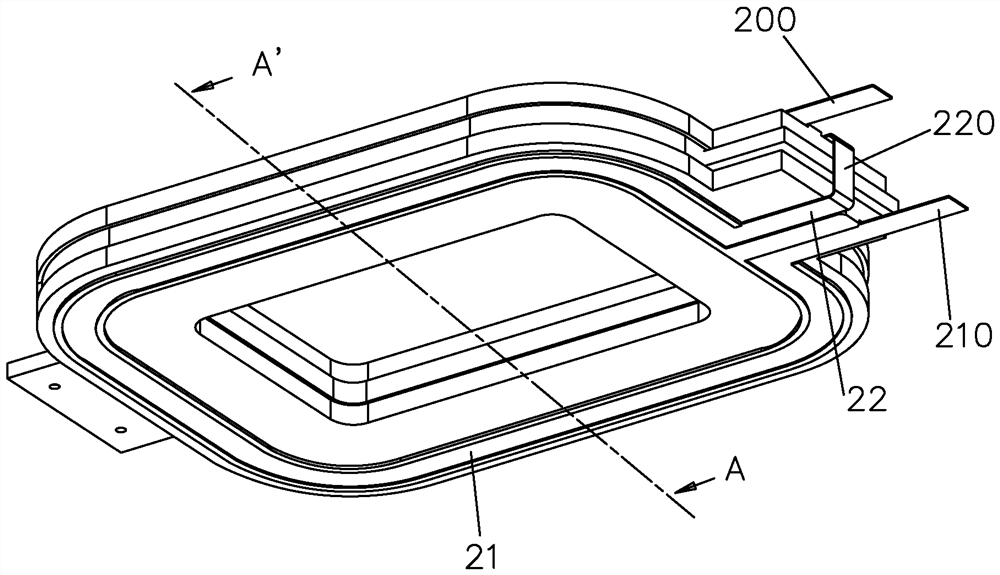

[0039] Please also refer to Figure 1 to Figure 5 , the present invention includes a first set of coils 1 and a second set of coils 2, wherein the first set of coils 1 has a first isolation layer 3 outside, and the second set of coils 2 is positioned on the first set of coils in a sandwiching manner. 1 on isolation layer 3, becomes as image 3 and Figure 4 The coil module shown.

[0040] In preferred embodiments disclosed in the present invention, such as figure 1 and Figure 5 As disclosed, the first set of coils 1 is made by disposing a conductive pattern 10 on an insulating substrate 11, for example, by disposing the conductive pattern 10 in the PCB through a printed circuit board hereinafter referred to as PCB manufacturing technology. The first group of coils 1; or, directly laying the conductive pattern 10 on the insulating substrate 11 t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap